Double-layer elevated structure for high-intensity area under limited clearance and construction method of double-layer elevated structure

A frame structure and lower layer technology, applied in the field of double-layer elevated structure and its construction, can solve the problems of compressing the clearance under the bridge, the weight of the upper structure of the double-layer elevated, and the height of the bridge structure, so as to solve the problem of earthquake resistance and the effect of shock absorption and isolation Obvious, low overall height of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

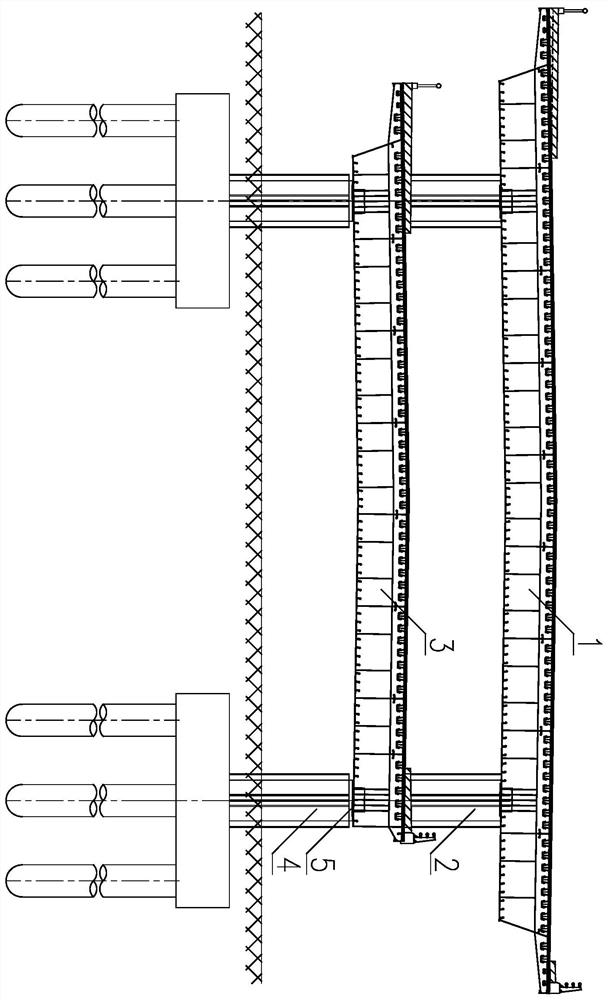

[0032] Such as Figure 1-2 As shown, this embodiment provides a double-layer elevated structure for high-intensity areas with limited clearance, including: a frame structure fixedly connected to the upper end surface of the lower column 4 through the support 5;

[0033] Wherein, the support 5 is a shock-absorbing and isolating support; the frame structure includes: the upper main beam 1, the upper column 2 and the lower main beam 3;

[0034] The lower end surface of the upper main beam 1 is fixedly connected to the upper end surface of the upper column 2 , and the lower end surface of the upper column 2 is fixedly connected to the upper end surface of the lower main beam 3 .

[0035] As a preferred embodiment, the lower end surface of the lower main beam 3 is fixedly connected to the upper end surface of the lower column 4 through the support 5 .

[0036] As a preferred embodiment, the upper column 2 is located at the left and right ends of the lower main beam 3 .

[0037] A...

Embodiment 2

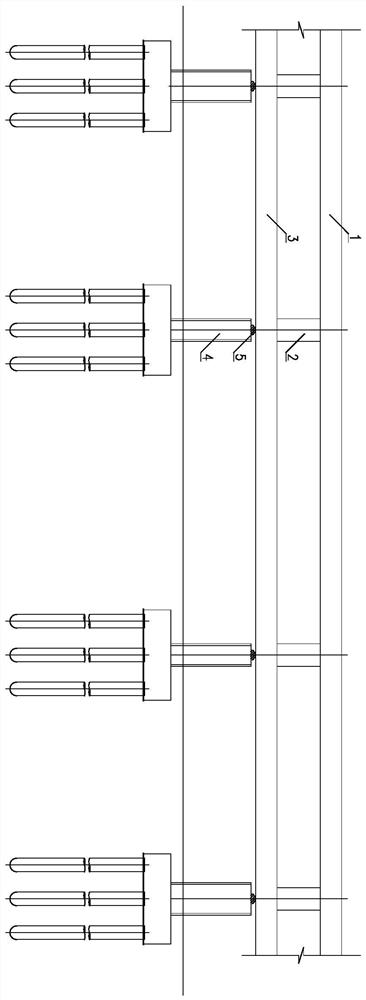

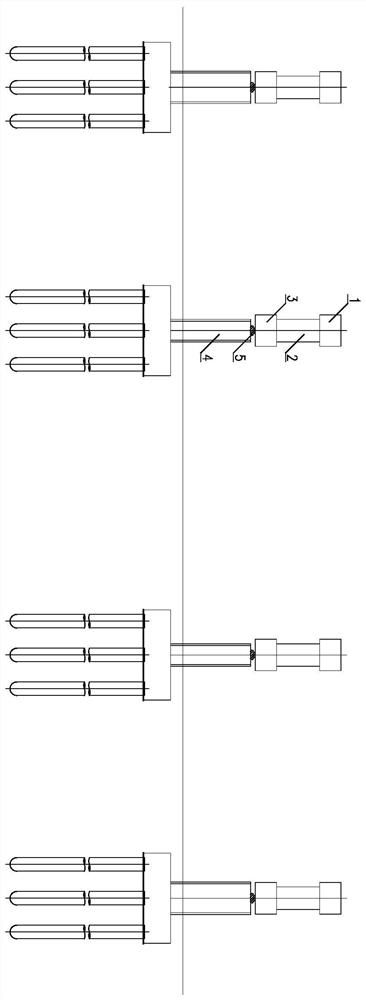

[0041] Such as Figure 3-5 As shown, this embodiment provides a construction method for a double-deck elevated structure as described in Embodiment 1, and the steps include:

[0042] Step S1: constructing the lower column 4;

[0043] Step S2: placing the support 5 on the upper end of the lower column 4;

[0044] Step S3: forming a transverse frame on the ground at the connection between the upper main beam 1 and the lower main beam 3 and the upper column 2;

[0045] Step S4: Overall construction of the transverse frame on the upper end of the support 5;

[0046] Step S5: set up a support on the ground, and construct the remaining main beam 3 of the lower floor;

[0047] Step S6: Erecting supports on the lower main girder 3 and constructing the remaining upper main girder 1 to obtain the double-layer elevated structure.

[0048] To sum up, the shock-isolation and anti-seismic method adopted by the double-deck elevated structure of the present invention has obvious shock-abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com