Tying-bar type cable-stayed bridge system

A cable-stayed bridge and tie-rod technology, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as difficulty in replacement, increase in deflection of main beams and negative bending moments of side beams, and achieve clear force and shock absorption. Good performance, easy to replace effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in combination with specific embodiments and examples.

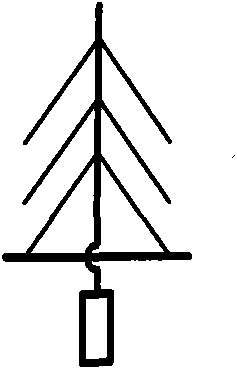

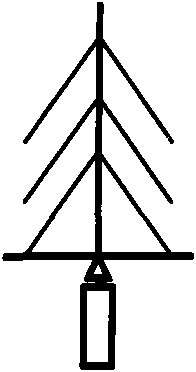

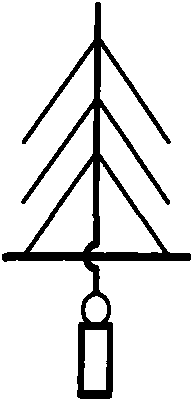

[0020] Such as Figure 2-3 A tie-rod single-tower cable-stayed bridge system of the present invention is shown, which includes a main pier 1 and a plurality of piers 2 spaced apart from the main pier, and is erected on the main pier through a supporting base 3 And the main girder 4 on a plurality of bridge piers, there is a groove 5 on the bottom surface of the main girder at the position of the main pier, and the position of the main pier at the position of the groove is provided with two main beams inserted in the groove Pier corbels 6, each main pier corbel 6 is connected to one end of a plurality of steel strand tie rods 7, and the other end of the plurality of steel strand tie rods is connected to the main beam end 8 on the pier.

[0021] Generally, single-tower cable-stayed bridges with small and medium spans adopt a structural system of towers, piers, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com