A kind of super high-rise building core tube steel column connection structure and core tube construction method

A technology for connecting structures and core tubes, which is applied in the direction of building construction, construction, and building material processing, etc., can solve problems such as poor firmness and lower overall strength of the core tube structure, and achieve pressure reduction, self-strength improvement, and space size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Attached to the following Figure 1-9 This application will be described in further detail.

[0054] The embodiment of the present application discloses a steel column connection structure for a core tube of a super high-rise building.

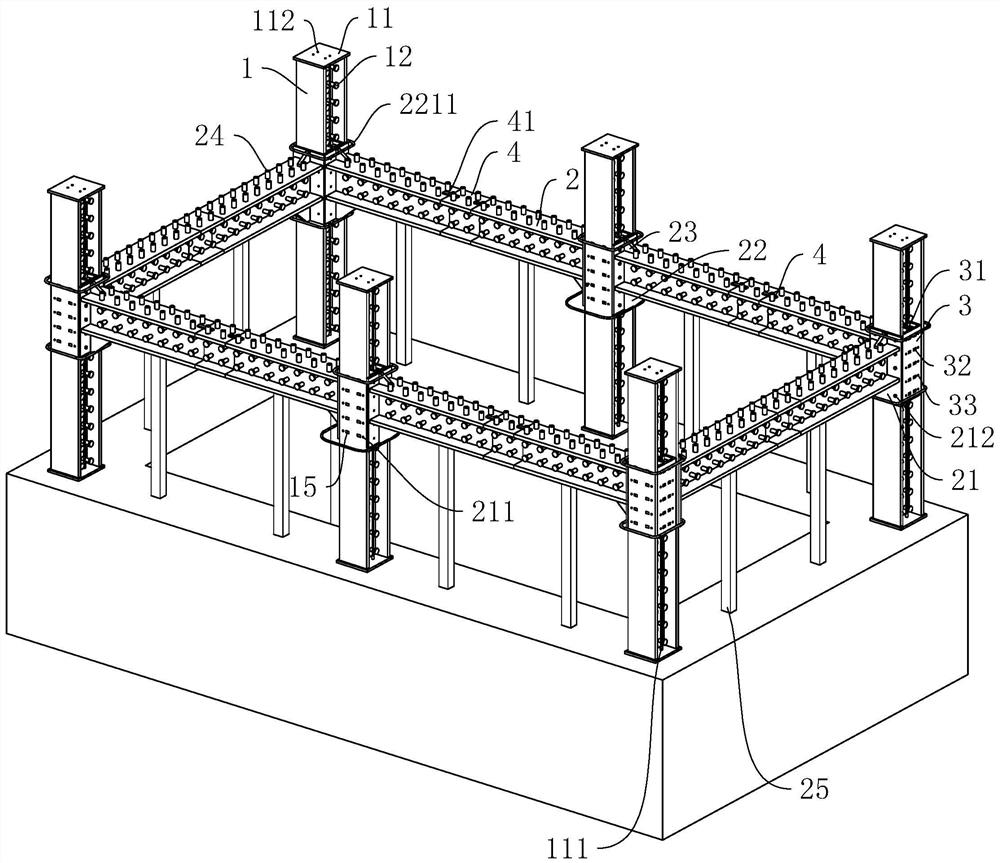

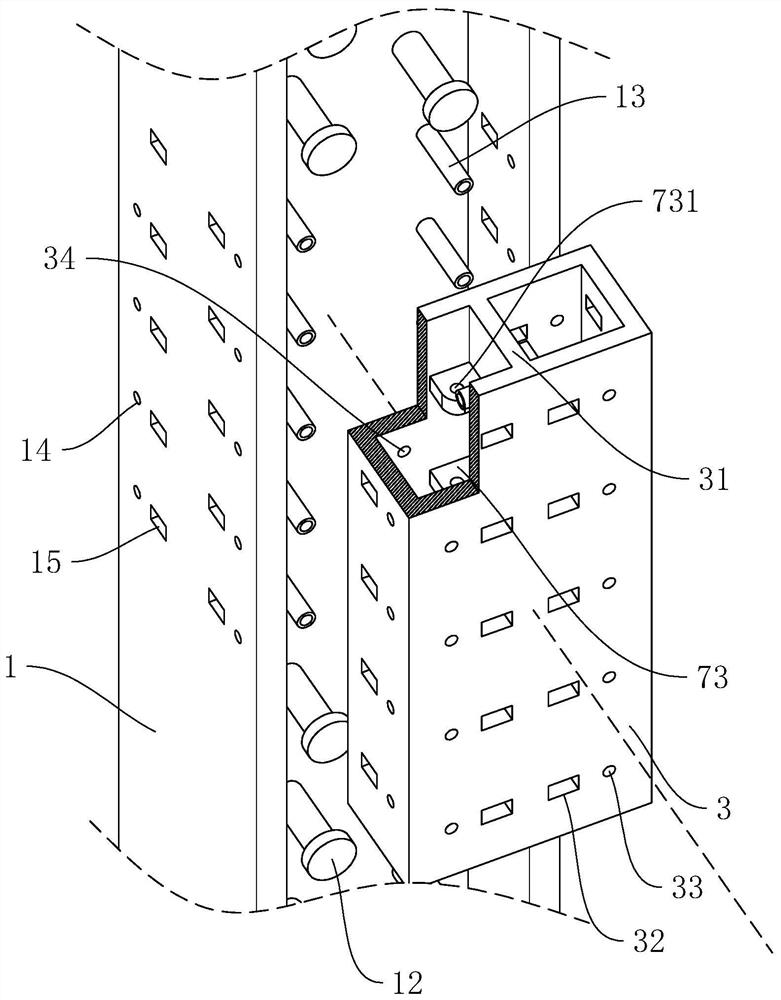

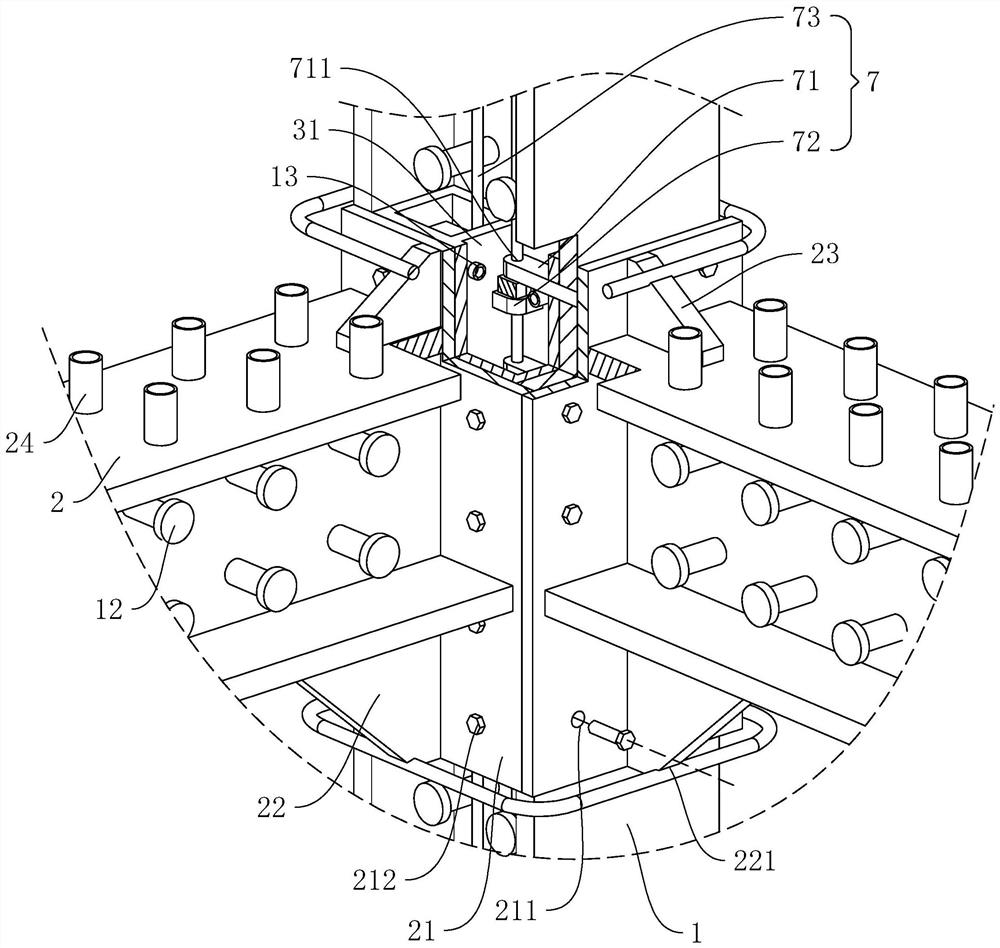

[0055] refer to figure 1 , the steel column connection structure of the core tube of the super high-rise building includes a steel column 1, a beam 2 and a reinforcement frame 3, the steel column 1 is vertically arranged and is H-shaped steel, and the top and bottom ends of the steel column 1 are welded with flanges for connection. Plate 11, the fixing plate 11 at the bottom end of the steel column 1 is flanged to the fixing plate 11 at the top of the steel column 1 below; the beam 2 is horizontally arranged, and one end is welded with a flange plate 21, the beam 2 is also H-shaped steel, and the upper surface of the beam 2 A reinforcing rib plate 23 is welded near the flange plate 21 , and the reinforcing rib plate 23 is fixedly weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com