Detection method and detection device for load state of lead screw transmission mechanism

A technology of load state and transmission mechanism, applied in the testing of machine/structural components, measuring devices, testing of mechanical components, etc., can solve the problems of long testing period and high testing cost, and achieve lower testing costs, high promotion value, and reduced testing costs. The effect of the number of equipment failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0024] The invention discloses a method for detecting the load state of a lead screw transmission mechanism, comprising the following steps:

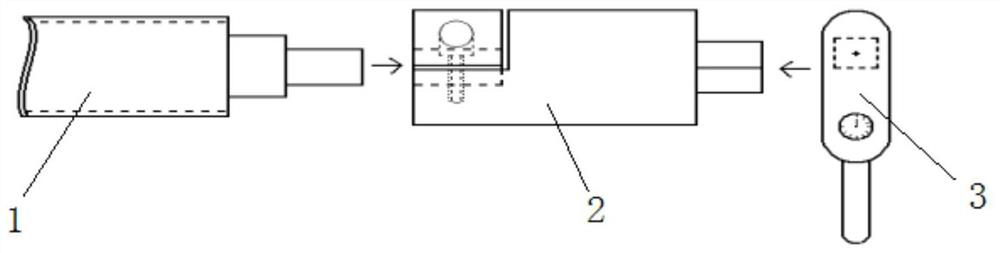

[0025] S1. Connect the connector 2 at one end of the lead screw 1, and connect the other end of the connector 2 with the driving device 3 with a torque gauge;

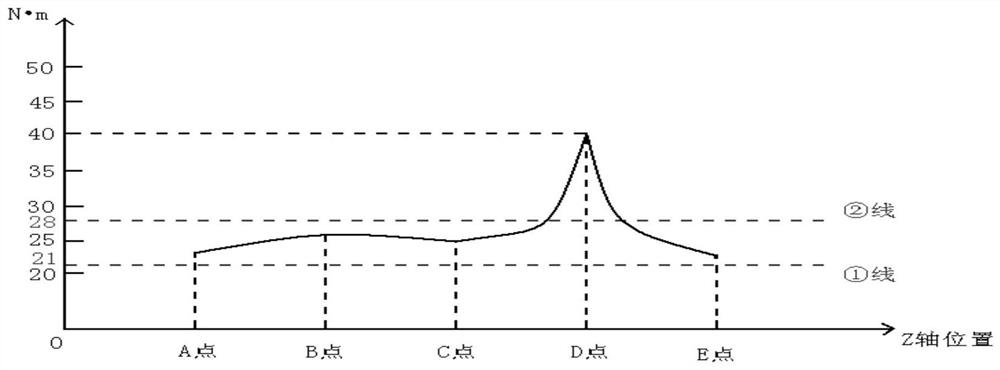

[0026] S2. Drive the connecting piece 2 to rotate through the driving device 3, and the connecting piece 2 drives the lead screw 1 to rotate. The driving device 3 displays the value through the transmission torque, collects the torque value through the torque meter, and compares the multi-point measurement data with the equipment control parameters. , the location where the data value is abnormal is the exact location of the fault point to find out the fault point.

[0027] Specifically, by us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com