Filling element, filling system and method for filling containers

A technology for filling components and containers, applied in liquid filling, transportation and packaging, using back pressure perfusion, etc., can solve problems such as technical cost and power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

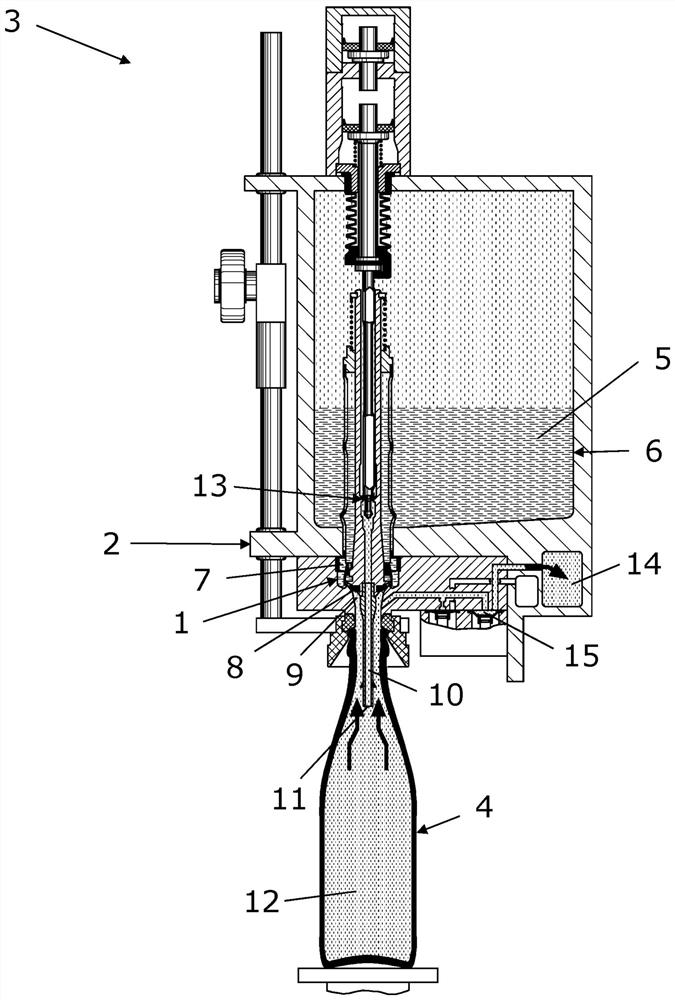

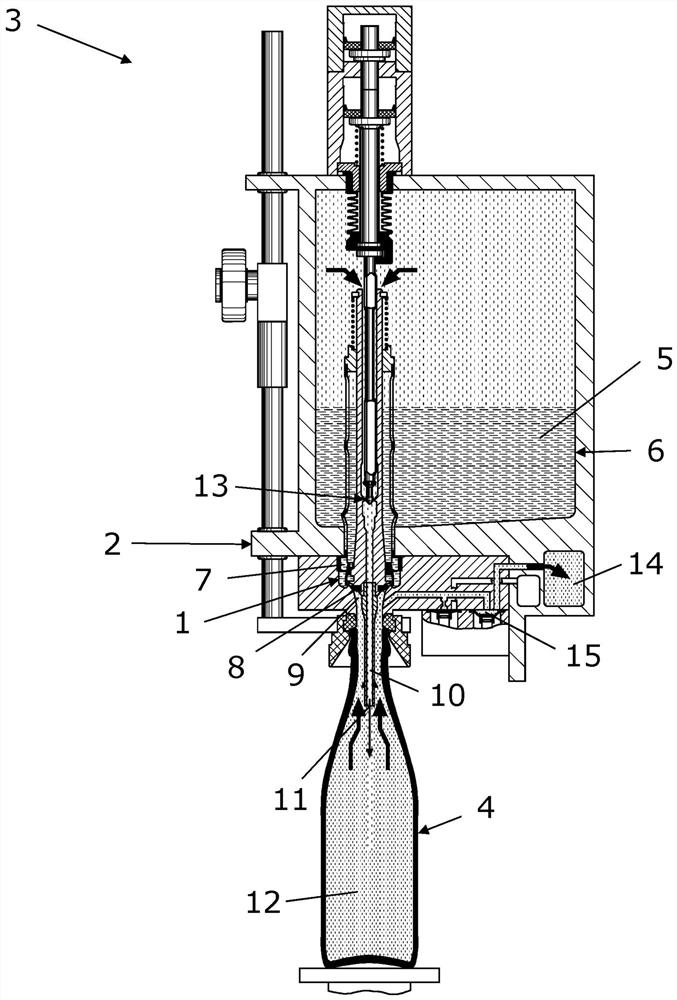

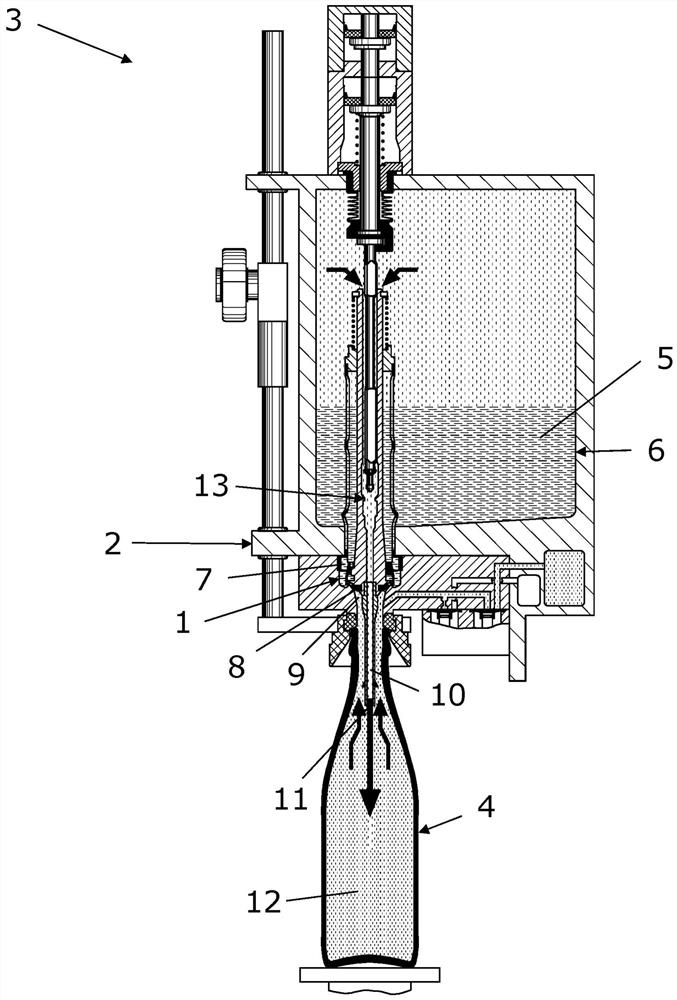

[0043] Figures 1a-1e A longitudinal section through a filling element 1 according to the invention is shown in each case by way of example at different points in time during the filling process. Here, the filling element 1 is arranged on a delivery element 2 of a filling system 3 , of which only a section is shown here.

[0044] Preferably during the filling process a container 4 is connected to the filling element 1 according to the invention, which container 4 is to be filled with a liquid filling 5 which is prepared in a filling reservoir 6 . exist Figures 1a-1e In the figure, the container 4 is shown as a bottle, however, the filling element 1 and the associated filling method are also suitable for other containers, such as jars or cups, with minor modifications customary in the industry.

[0045] In principle, every kind of liquid that can be filled in the container 4 can be considered as the liquid filler 5, however, in particular, the filling element 1 and the filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com