Preparation method of high-freeze-thaw-stability and high-internal-phase emulsion capable of 3D printing

A freeze-thaw stability, high internal phase emulsion technology, applied in the field of edible emulsion preparation, can solve the problems of food emulsion quality reduction, instability, easy flocculation, coalescence oil-water separation, etc., to achieve high freeze-thaw stability , expand the scope of application, and improve the effect of economic added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

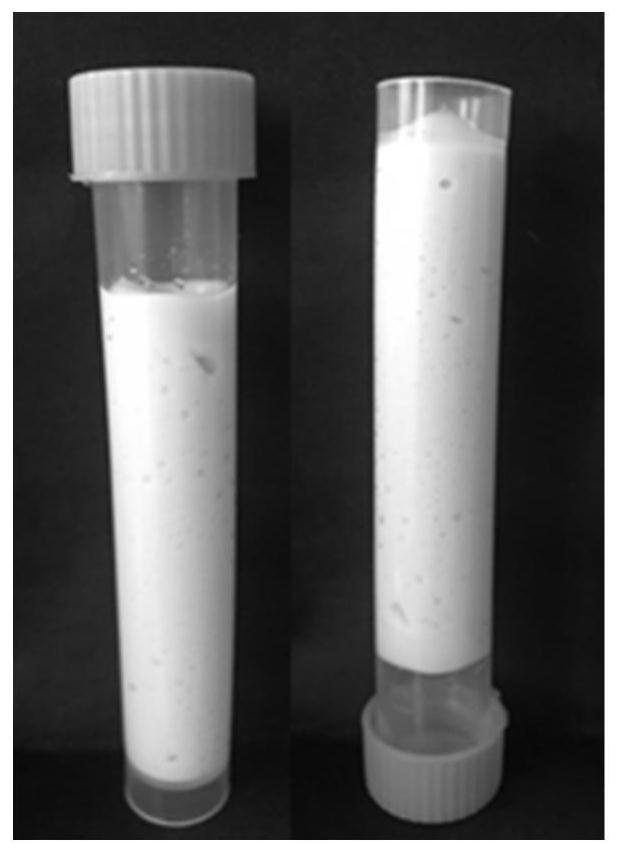

Image

Examples

Embodiment 1

[0053] A method for preparing a 3D printable high internal phase emulsion with high freeze-thaw stability, comprising the steps of:

[0054] S1. Preparation of Atlantic cod protein crude extract: take Atlantic cod meat and deionized water, mix them at a weight ratio of 1:10, and homogenize at 10,000 rpm for 3 minutes to obtain a homogenate; adjust the pH of the homogenate to 10.5 with 6N NaOH solution, and Stir at 100rpm and 4°C for 2h, centrifuge at 10,000rpm for 20min, take the supernatant; adjust the pH of the supernatant to 4.5 with 2N hydrochloric acid, let stand at 4°C for 30min, centrifuge at 10,000rpm for 5min, and take the precipitate as Atlantic cod protein crude extract.

[0055] S2, Maillard reaction preparation of water phase: the Atlantic cod protein crude extract obtained in step S1 is mixed with deionized water, and the pH of the homogenate is adjusted to 10 with 6N NaOH solution, and the concentration of the Atlantic cod protein crude extract is 30 mg / The At...

Embodiment 2

[0061] A method for preparing a 3D printable high internal phase emulsion with high freeze-thaw stability, comprising the steps of:

[0062] S1. Preparation of Atlantic cod protein crude extract: Take Atlantic cod meat and deionized water, mix them at a weight ratio of 1:10, and homogenize at 10,000 rpm for 3 minutes to obtain a homogenate; adjust the pH of the homogenate to 10.5 with 6N NaOH solution , and at 100 rpm, stirred at 4°C for 2h, centrifuged at 10,000rpm for 20min, and took the supernatant; adjusted the pH of the supernatant to 4.5 with 2N hydrochloric acid, left it at 4°C for 30min, centrifuged at 10,000rpm for 5min, and took the precipitate. Crude protein extract of Atlantic cod.

[0063] S2, Maillard reaction to prepare the water phase: use water to mix the Atlantic cod protein crude extract obtained in step S1 with deionized water, adjust the pH of the homogenate to 10 with 6N NaOH solution, and obtain the Atlantic cod protein crude extract concentration of 50...

Embodiment 3

[0068] A method for preparing a 3D printable high internal phase emulsion with high freeze-thaw stability, comprising the steps of:

[0069] S1. Preparation of Atlantic cod protein crude extract: Take Atlantic cod meat and deionized water, mix them at a weight ratio of 1:10, and homogenize at 10,000 rpm for 3 minutes to obtain a homogenate; adjust the pH of the homogenate to 10.5 with 6N NaOH solution , and at 100 rpm, stirred at 4°C for 2h, centrifuged at 10,000rpm for 20min, and took the supernatant; adjusted the pH of the supernatant to 4.5 with 2N hydrochloric acid, left it at 4°C for 30min, centrifuged at 10,000rpm for 5min, and took the precipitate. Crude protein extract of Atlantic cod.

[0070] S2. Prepare the water phase: use water to mix the crude Atlantic cod protein extract obtained in step S1 with deionized water, adjust the pH of the homogenate to 10 with 6N NaOH solution, and obtain a protein with a concentration of 50 mg / ml of the crude Atlantic cod protein ext...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap