An electric tooth extraction device

An electric and dental technology, applied in dentistry, dentist forceps, dental restorations, etc., can solve the problems of increased infection risk, time-consuming and laborious, large wound area, etc., to reduce the risk of infection, simple and efficient operation, and small wound area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will hereinafter be described in more detail with reference to the accompanying drawings, which illustrate embodiments of the invention. However, the present invention may be embodied in many different forms and should not be construed as limited by the embodiments set forth herein. Rather, these embodiments are presented so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art. In the drawings, the size and relative sizes of layers and regions may be exaggerated for clarity.

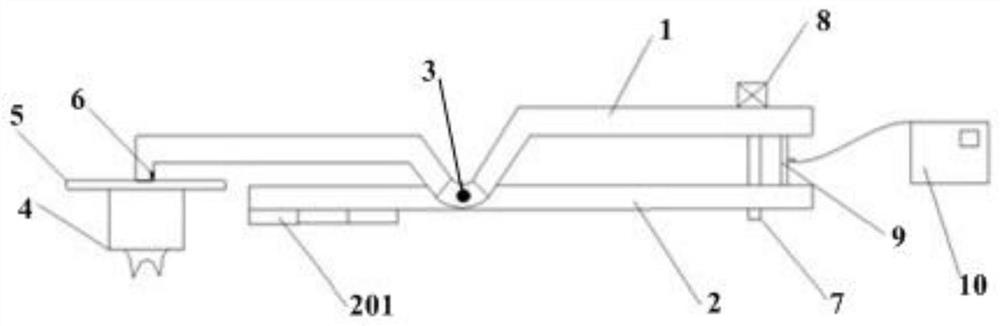

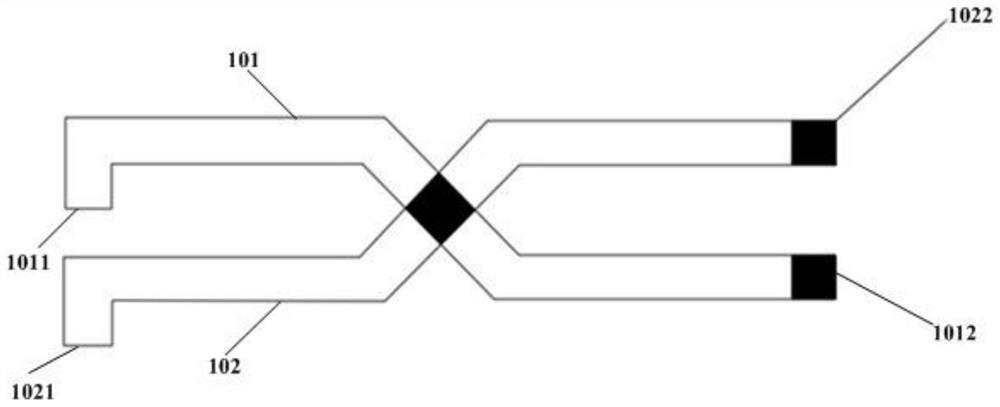

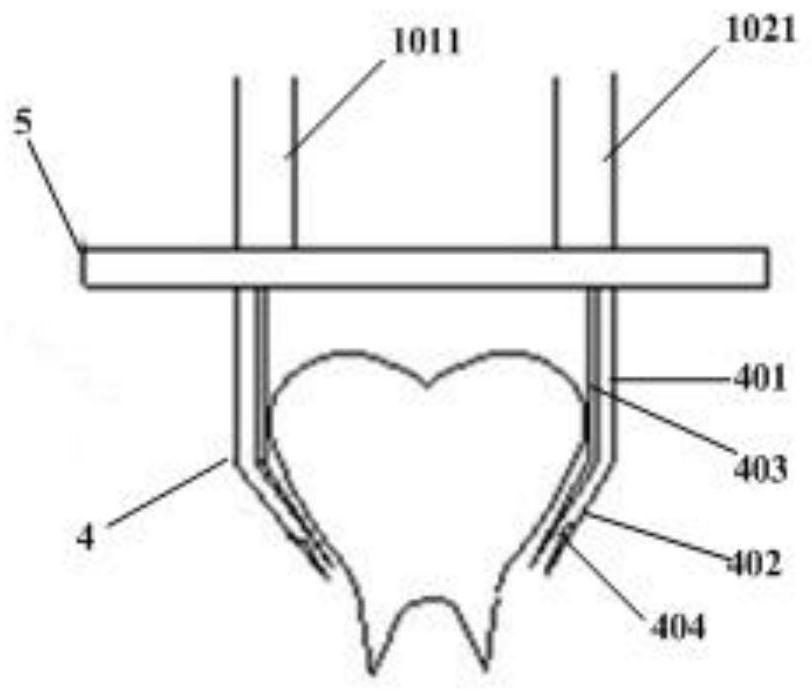

[0034] refer to Figure 1-5 , the present application provides an electric tooth extraction device, including a forceps assembly 1 , a support base 2 and a controller 10 . The clamp body assembly 1 includes a first clamp rod 101 , a second clamp rod 102 , a first clamping portion 1011 disposed at the front end of the first clamp rod 101 , a first clamping portion 1021 disposed at the front end of th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap