A heavy-duty high-strength steel lightweight side-opening double-door container structure

A high-strength steel, lightweight technology, applied in the direction of windows/doors, building components, building structures, etc., can solve the problems of increasing the lateral length of the car, easy to hit passing vehicles or roadside buildings, etc., to improve the flexibility of use , to facilitate the effect of induction alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

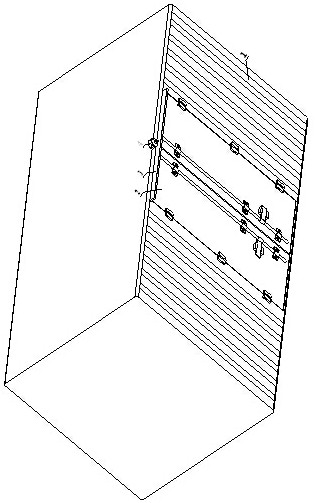

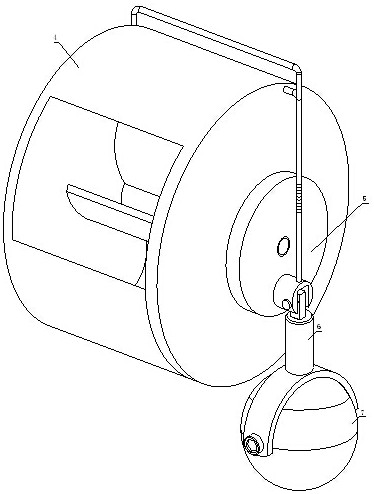

[0029] refer to Figure 1-2 , a heavy-duty high-strength steel lightweight side-opening double-door container structure, including a container main body 1, double doors 2 and a top plate 3, the double door 2 is arranged in the middle of one side of the container main body 1, and the top plate 3 is set on the upper end of the double door 2 On one side of the main body of the container 1, there is also an air control switch 4 arranged in the middle of the upper end of the top plate 3. A pusher 6 is arranged on one side of the air control switch 4, and the pusher 6 runs through the top plate 3, and an alarm ball 7 is arranged at the lower end , the lower third of the alarm ball 7 is on par with the double door 2 upper end faces.

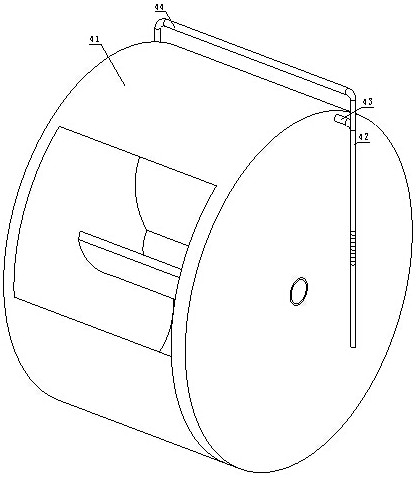

[0030] refer to Figure 3-4And 7, a heavy-duty high-strength steel lightweight side-opening double-door container structure, the wind control switch 4 includes an air guide ring 41 fixedly arranged on the top plate 3, and the upper end of the air guide...

Embodiment 2

[0034] refer to Figure 1-2 , a heavy-duty high-strength steel lightweight side-opening double-door container structure, including a container main body 1, double doors 2 and a top plate 3, the double door 2 is arranged in the middle of one side of the container main body 1, and the top plate 3 is set on the upper end of the double door 2 On one side of the container main body 1, it also includes a wind control switch 4 arranged in the middle of the upper end of the top plate 3. One side of the wind control switch 4 is movably provided with a connection assembly 5 located directly above the center line of the double door 2. One of the connection assembly 5 The side is provided with a pusher 6, and the pusher 6 runs through the top plate 3, and the lower end is provided with an alarm ball 7, and the lower third of the alarm ball 7 is flat with the upper end surface of the double door 2.

[0035] refer to Figure 3-4 , a heavy-duty high-strength steel lightweight side-opening d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com