Mushroom cultivation workshop door

A workshop and mushroom technology, applied in the field of workshop doors, can solve the problems affecting the temperature and humidity of the germ chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

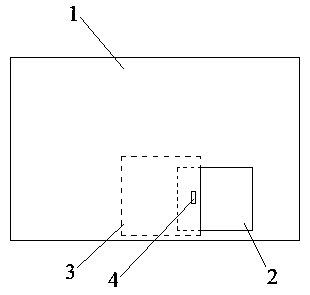

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0011] A door for a mushroom breeding workshop, characterized in that it includes a sliding door 1, the sliding door 1 is composed of two door panels and an insulating layer filled between the two door panels, and the bottom of the sliding door 1 is also provided with The entrance and exit 2, the bottom end of the entrance and exit 2 is provided with a distance from the bottom of the sliding door 1, and also includes a drawing door 3 installed between the two door panels of the sliding door 1 to block the entrance and exit 2, on the drawing door 3 There is a pull groove 4. The drawing door 3 is rectangular in shape and 1.6-2m high.

[0012] Since the sliding door 3 installed between the two door panels of the sliding door 1 can block the entrance and exit 2, in the actual production and use process, when there is no need to transport the fungus racks, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com