Lifting travelling crane type vertical separation garbage compressor moving device and method

A garbage compactor and mobile device technology, which is applied in the direction of hoisting devices, lifting frames, presses, etc., can solve the problems of small footprint, achieve the effects of occupying less ground space, fast moving and changing positions, and convenient daily maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

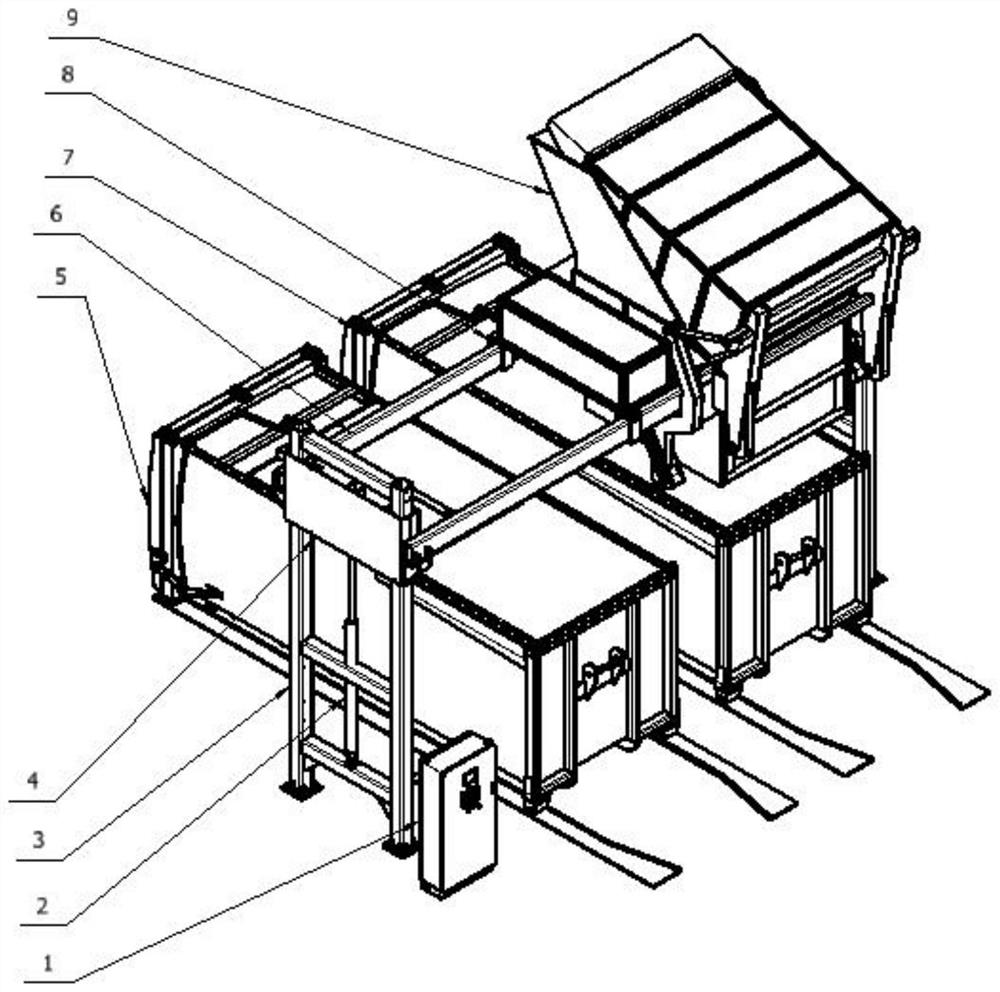

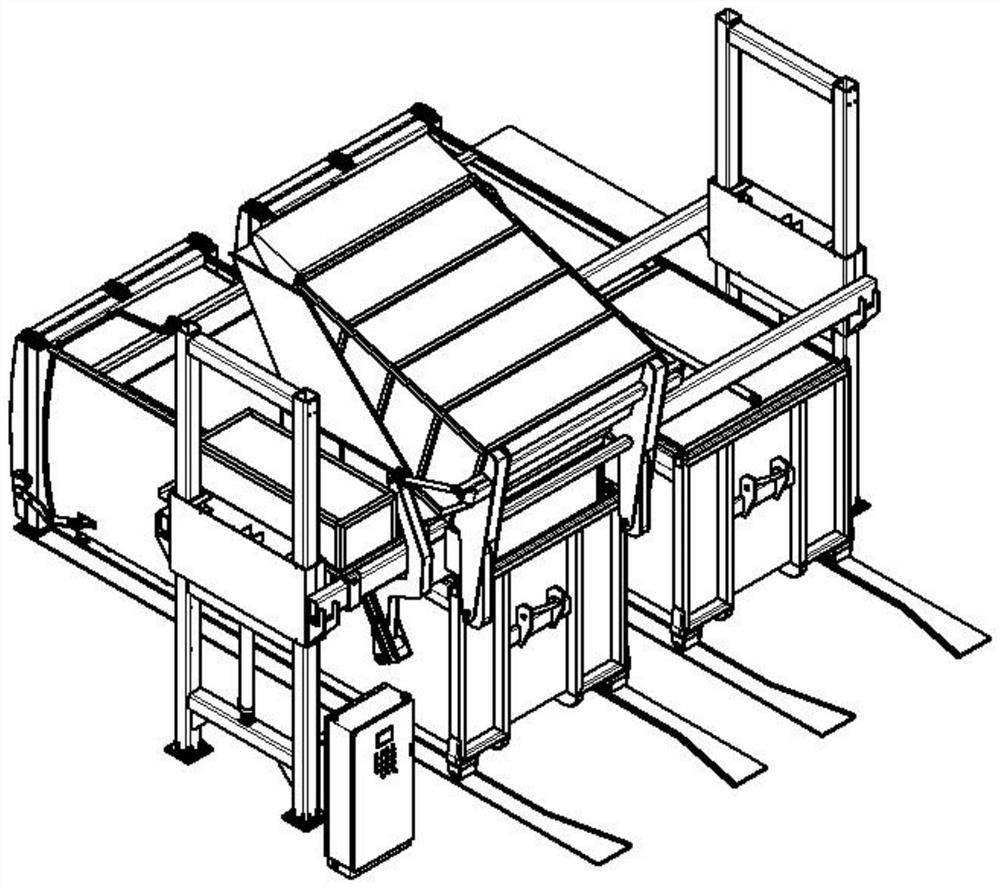

[0029] A mobile device for lifting and driving type vertically separating garbage compressors. A vertical movement block and a lifting drive device for pushing the vertical movement block are respectively installed on the driving frame, and a driving crossbeam is connected between the two vertical movement blocks, and a translation block is installed on the driving crossbeam. The translation driving device that pushes the translation pulley; the vertical split type garbage compressor, the vertical split type garbage compressor is installed on the compressor moving pulley, corresponding to the feeding port of any garbage container; the control system, the control system is respectively connected with the Garbage container, lifting crane, and vertical split garbage compressor are connected.

[0030] The lifting driving device adopts an oil cylinder, and the translation driving device adopts an oil cylinder or a geared motor. The vertical moving block is slidably fitted on the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com