A hydraulic hinge with adjustable buffer speed for double opening

A hydraulic hinge and speed technology, applied in the field of hinges, can solve the problems of unadjustable buffer speed, short service life, affecting appearance, etc., and achieve the effect of adjustable return buffer speed, ensuring uniform motion and improving buffer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: A double-opening hydraulic hinge with adjustable buffer speed.

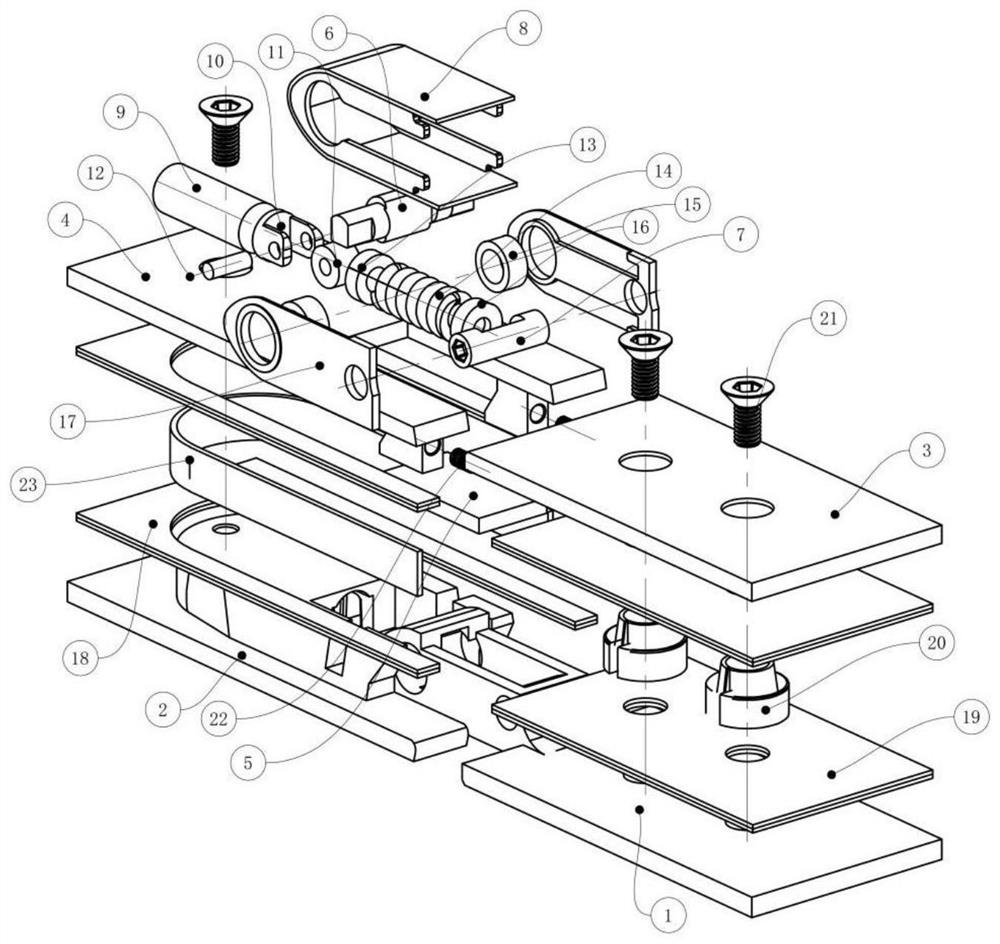

[0028] refer to Figure 1 to Figure 8 As shown, a hydraulic hinge with double-open buffer speed adjustable, including:

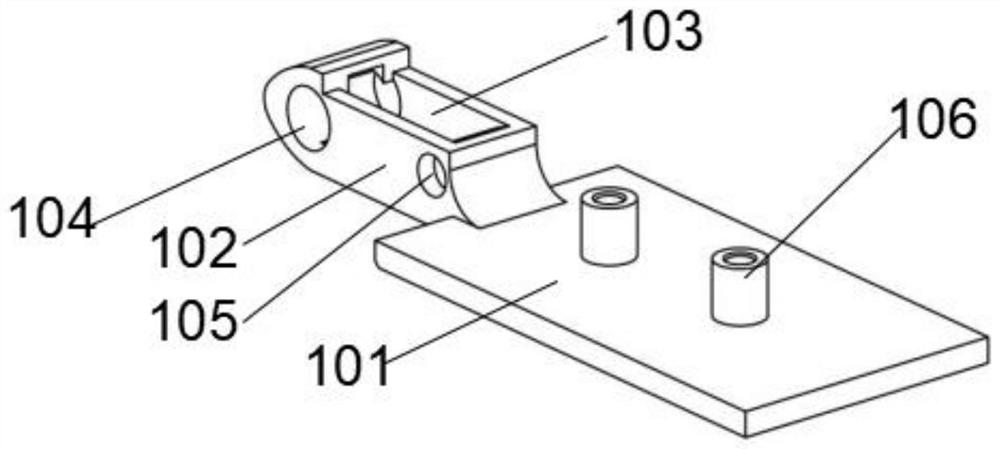

[0029]The fixed seat 1, the fixed seat 1 includes a fixed seat plate 101, the front end of the fixed seat plate 101 is provided with a rotating shaft mounting seat 102, the outer side of the rotating shaft mounting seat 102 is sleeved with a buffer shell 8, and the front end of the buffer shell 8 It is arranged in an arc shape so as to contact the buffer wheel 11 at the front end of the buffer cylinder 9 with different pressures during the rotation process to realize the pressing of the buffer cylinder 9. A spring installation groove 103 is provided on the rotating shaft mounting seat 102 for installing the spring buffer assembly , the front end of the spring mounting groove 103 is provided with a rotating shaft mounting hole 104 for installing the central rotating shaft 6...

Embodiment 2

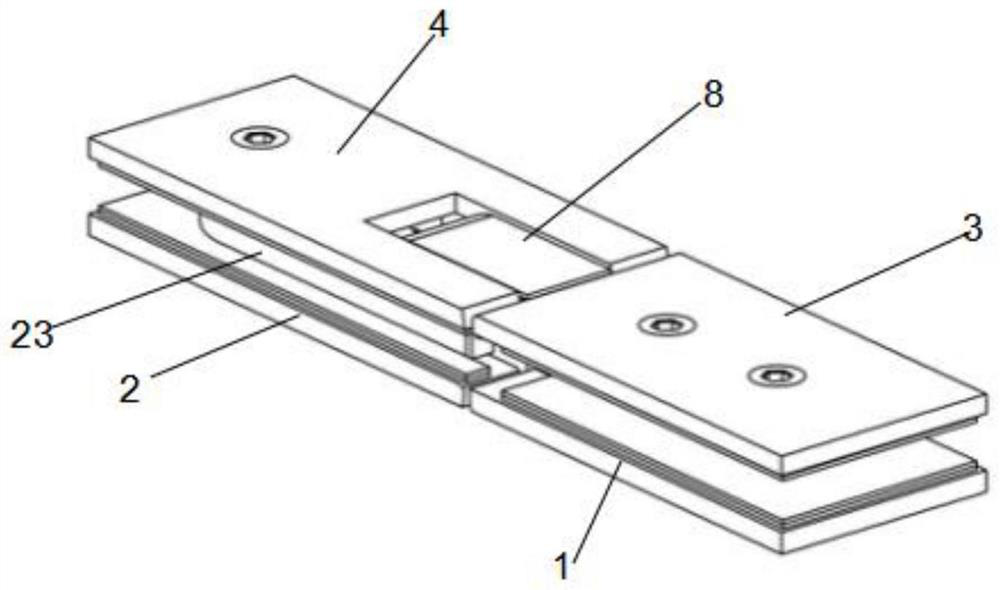

[0038] Embodiment 2: A double-opening hydraulic hinge with adjustable buffer speed.

[0039] refer to Figure 9 As shown, a double-opening hydraulic hinge with adjustable cushioning speed, the fixed seat 1 is replaced by a mounting plate, and the distance between the mounting plate and the movable seat 2 is set at 90°, and other technical features are the same as in embodiment 1.

Embodiment 3

[0040] Embodiment 3: A double-opening hydraulic hinge with adjustable buffer speed.

[0041] refer to Figure 10 As shown, a double-opening buffer speed-adjustable hydraulic hinge, the angle between the fixed seat 1 and the movable seat 2 is set to 135°, and the rest of the technical features are the same as in the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap