Gear device for railway vehicle

A technology for gear devices and railway vehicles, which is applied to transmission parts, gear lubrication/cooling, belts/chains/gears, etc., and can solve problems such as cumbersome maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

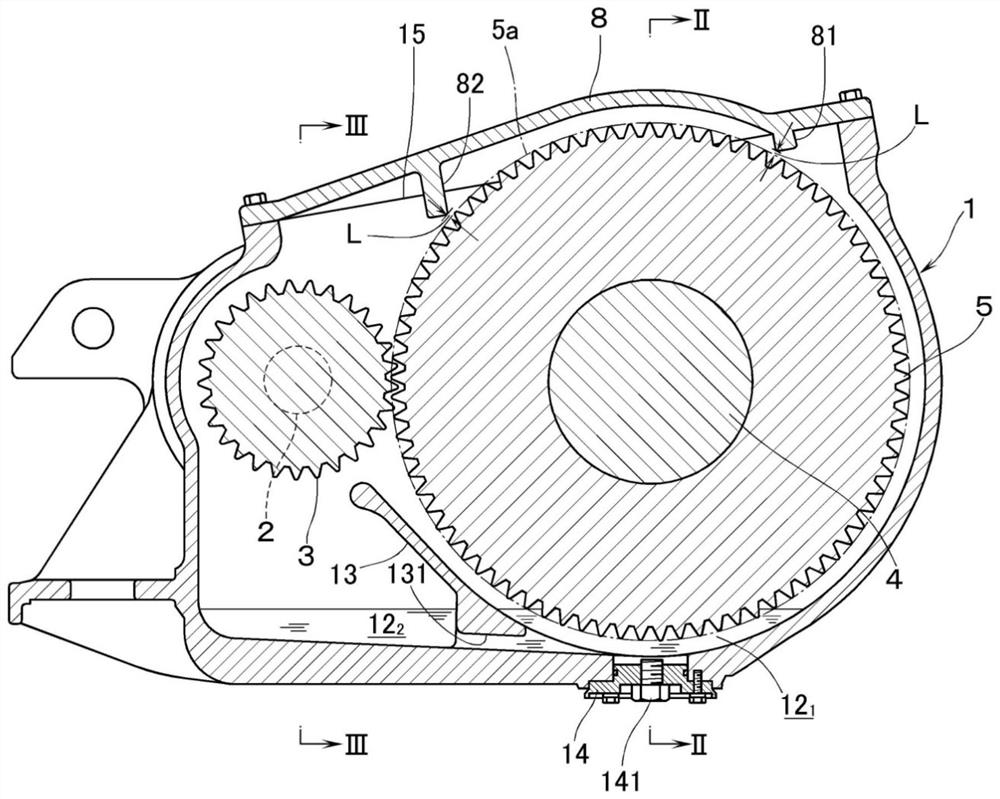

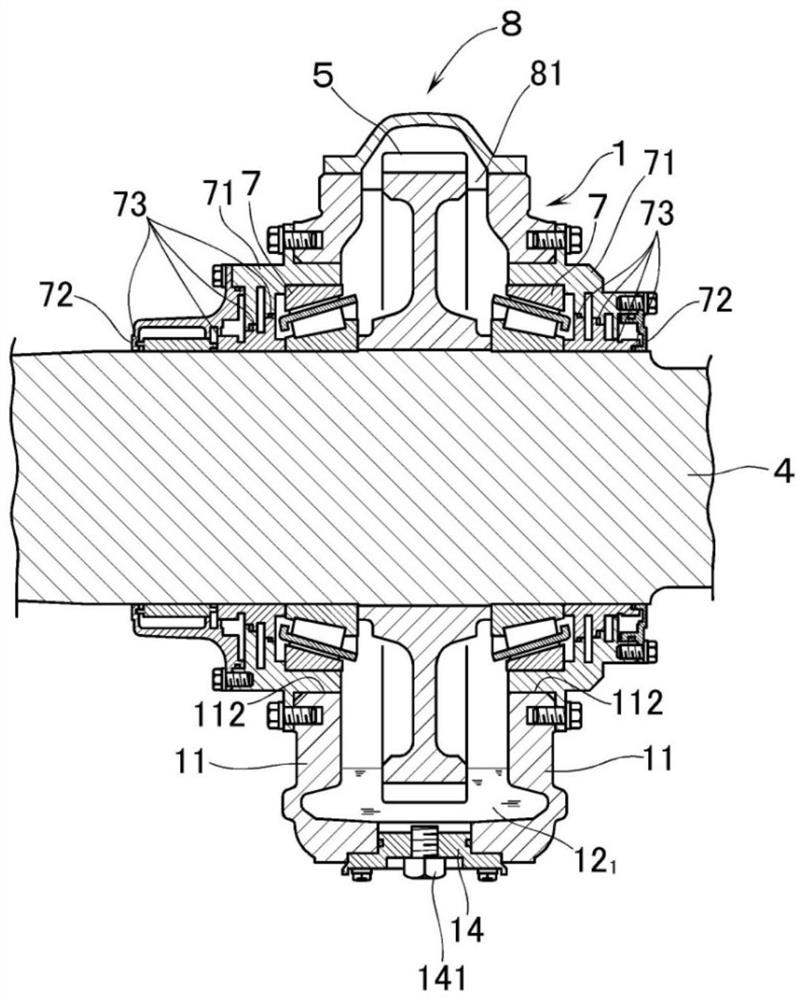

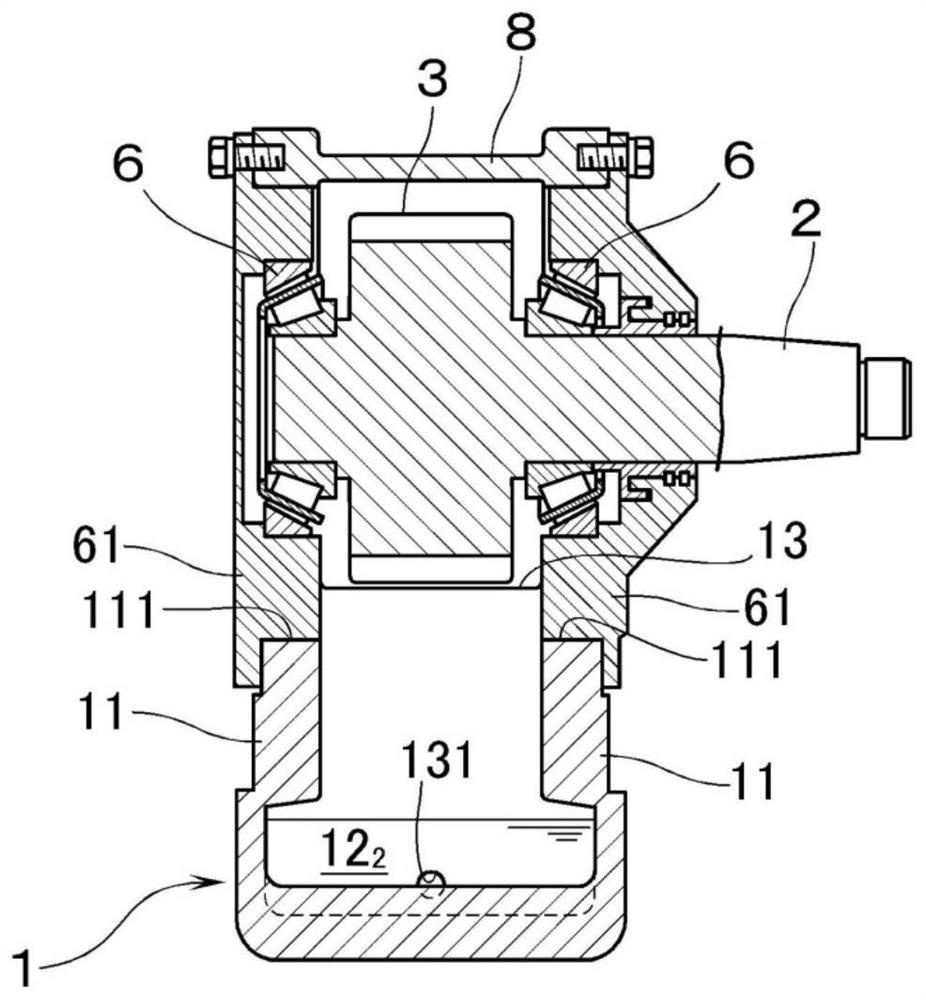

[0016] refer to figure 1 , The railway vehicle gear device according to the embodiment of the present invention includes a gear case 1 . In the gear box 1, a pinion gear 3 and a bull gear 5 are housed in a state of meshing with each other in the horizontal direction. The pinion gear 3 is composed of a helical gear and is fixed to a drive source not shown in the figure. Input shaft 2 driven in rotation (see image 3 ), the large gear 5 is composed of a helical gear, and is fixed to the axle 4. refer to figure 2 , image 3 A pair of input shaft bearings 6 and 6 for supporting the input shaft 2 and a pair of axle shaft bearings for supporting the axle 4 are installed on the side wall parts 11 and 11 on both axial sides of the gearbox 1 . Bearing 7,7. Specifically, an opening 111 concentric with the input shaft 2 and larger in diameter than the pinion gear 3 , and an opening 112 concentric with the axle 4 and smaller in diameter than the bull gear 5 are formed in each side w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap