Semiconductor device and method for manufacturing same

A semiconductor, opposite-side technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

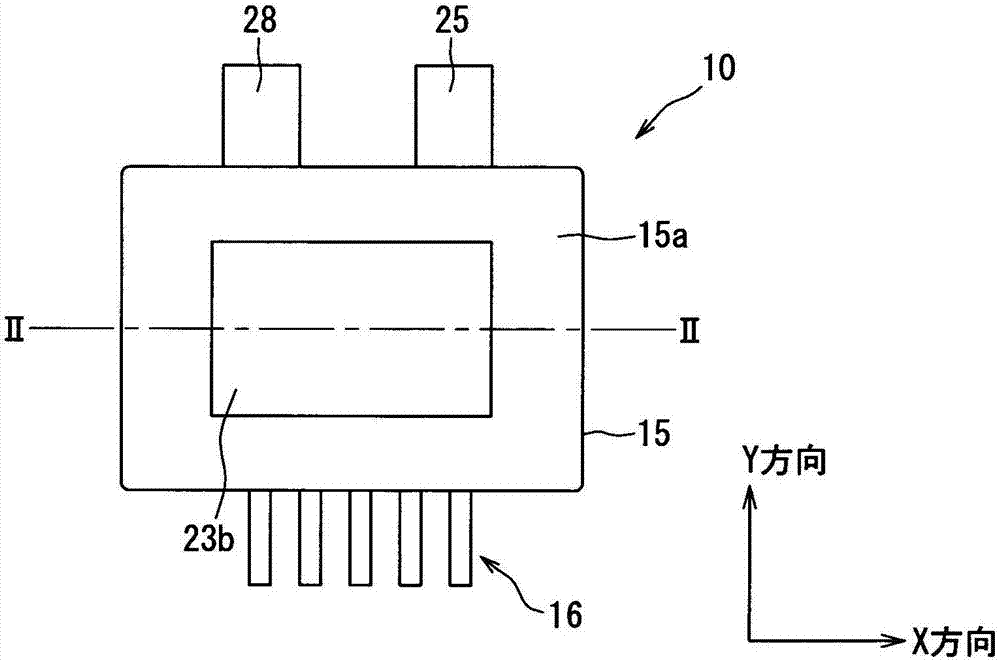

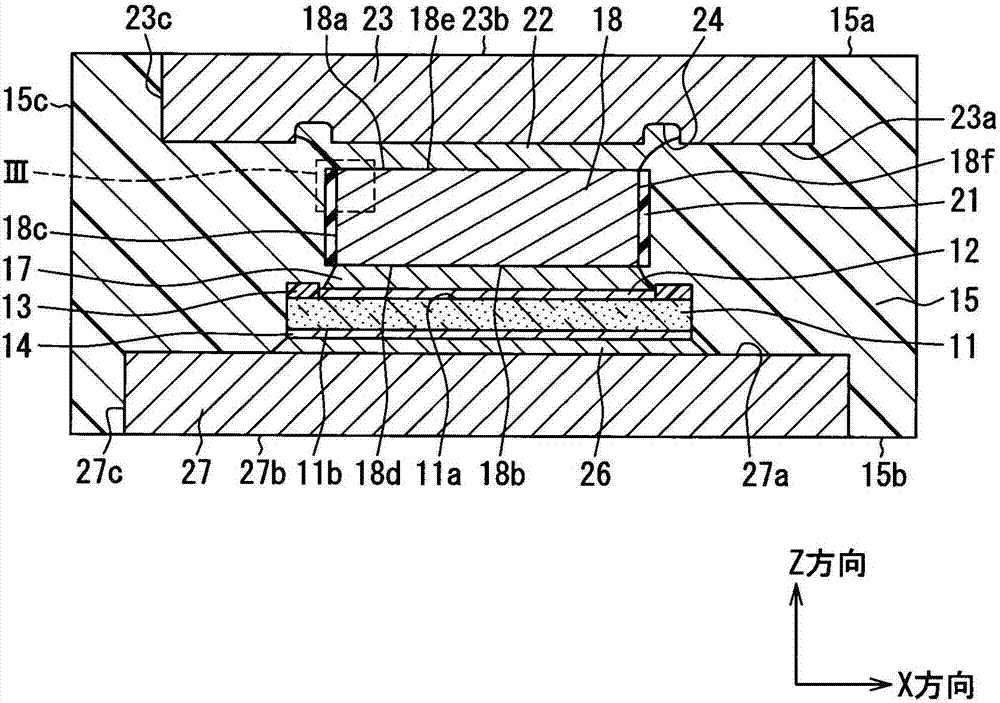

[0049] First, based on Figure 1 ~ Figure 3 , the schematic structure of the semiconductor device will be described.

[0050] Such as figure 1 as well as figure 2 As shown, the semiconductor device 10 includes a semiconductor chip 11 , a sealing resin body 15 , a terminal 18 , a first heat sink 23 , and a second heat sink 27 . Furthermore, the semiconductor device 10 includes signal terminals 16 and main terminals 25 and 28 as terminals for external connection. Such a semiconductor device 10 is known as a so-called 1-in-1 package constituting one of six arms of a three-phase converter, and is incorporated into, for example, a converter circuit of a vehicle.

[0051] The semiconductor chip 11 is formed by forming a power transistor such as an insulated gate bipolar transistor (IGBT) on a semiconductor substrate such as silicon. In this embodiment, an n-channel IGBT is formed, and a freewheel diode (FWD) connected in antiparallel to the IGBT is formed. That is, RC (Revers...

Embodiment 1

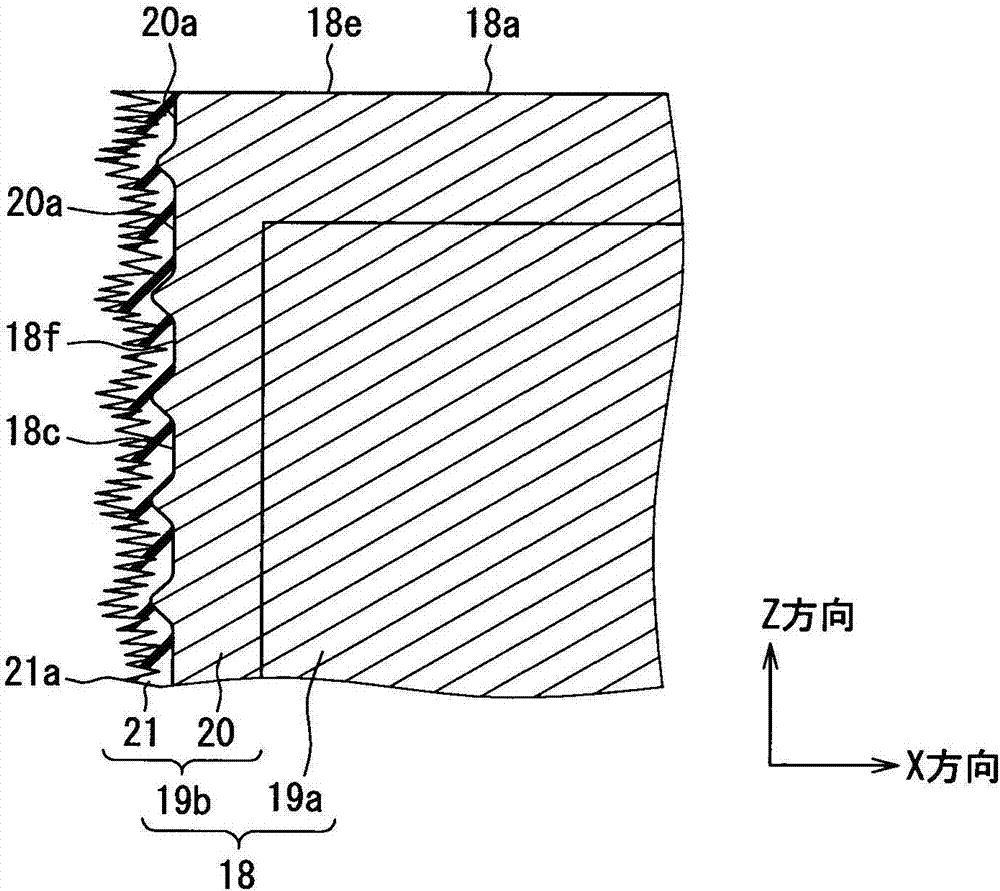

[0106] The present inventors confirmed the relationship between the presence or absence of the uneven oxide film 21 and the formation range of the uneven oxide film 21 and solder wetting. express its results in Figure 9 middle. At this time, the semiconductor device 10 was formed by the above-mentioned manufacturing method and evaluated. When there is no uneven oxide film 21, the amount of the second solder 22 that does not cause wetting and spreading to the joint 18 was used as a reference amount, and a comparison was made between the reference amount and the amount three times the reference amount. In addition, the formation range of the uneven oxide film 21 on the side surface 18c is set to the entire surface, from the end on the first opposing surface 18a side to 1 / 2 of the side surface 18c, and from the first opposing surface 18a side. These three types from the end up to 1 / 3 of the side 18c were compared. At this time, using an energy density of 12J / cm 2 Concavo-con...

Embodiment 2

[0111] The present inventors confirmed the relationship between the presence or absence of the metal thin film 20 , the type of the metal thin film 20 , the presence or absence of the uneven oxide film 21 , and the easiness of occurrence of solder bridges. express its results in Figure 10 middle. At this time, the semiconductor device 10 was formed by the above-mentioned manufacturing method and evaluated. That is, in the case of forming the uneven oxide film 21, at an energy density of 6 J / cm 2 The metal thin film 20 was irradiated with laser light, and then soldered by reduced-pressure reflow under a hydrogen atmosphere. Regarding the metal thin film 20 , the metal thin film 20 formed by electroplating Ni and the metal thin film 20 formed by electroless Ni plating were respectively evaluated.

[0112] In addition, in each case, the material tolerance target value (hereinafter, expressed as material tolerance Typ) and the material tolerance max were evaluated. The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com