Centrifugal casting machine for manufacturing rotor

A centrifugal casting and rotor technology, used in the manufacture of stator/rotor bodies, etc., can solve the problems of gaps between silicon steel sheets, cumbersome operations, and the pressure cannot be uniformly transmitted to the iron core, and achieve the effect of inhibiting inflow or loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, preferred embodiments of the present invention will be described in detail in conjunction with the accompanying drawings. In describing the embodiments of the present invention, if it is judged that the detailed description of related known functions or configurations may unnecessarily obscure the gist of the present invention, the detailed description will be omitted.

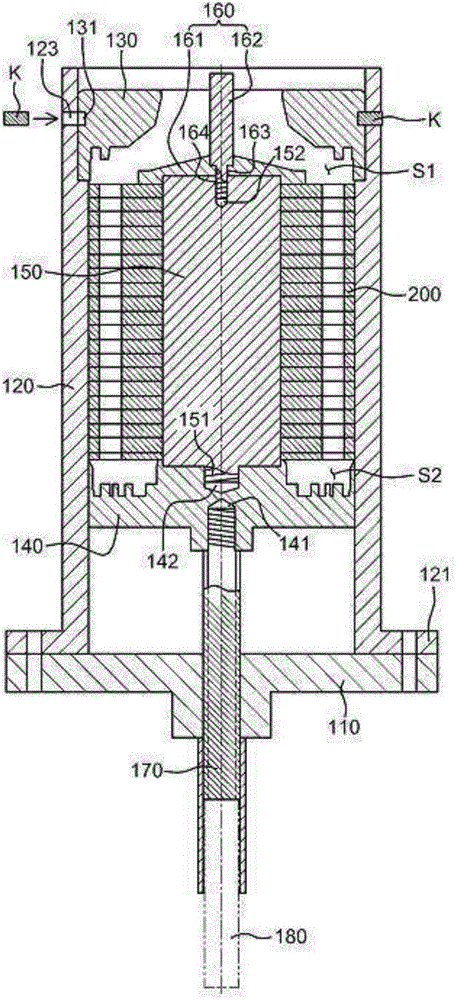

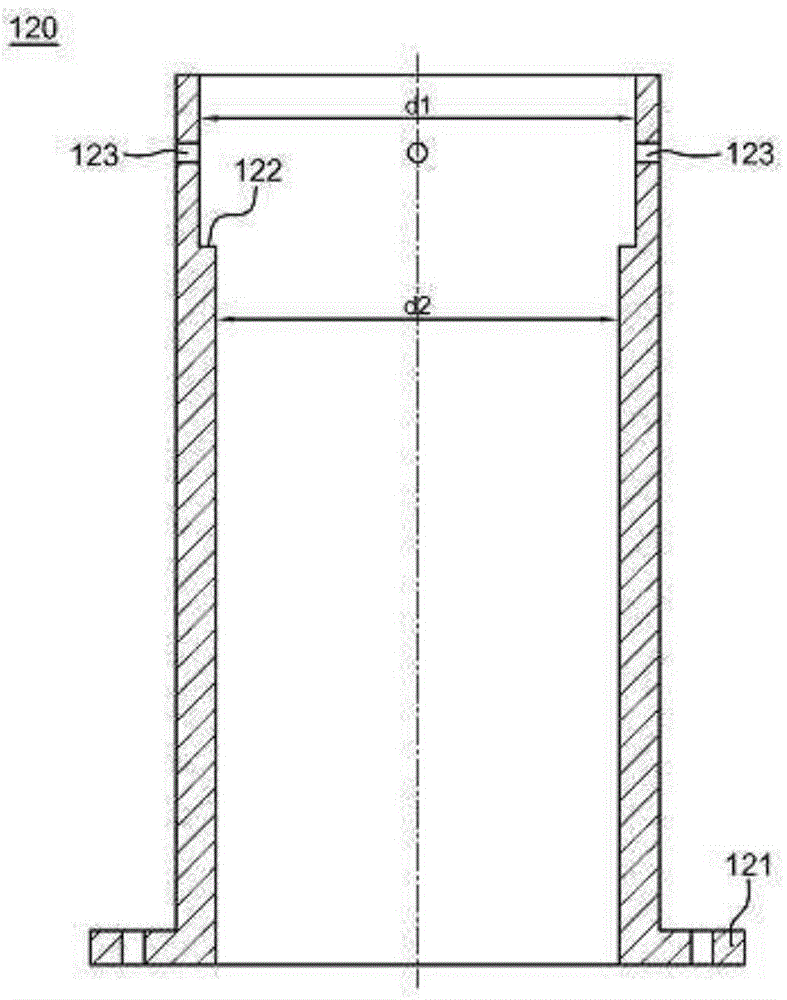

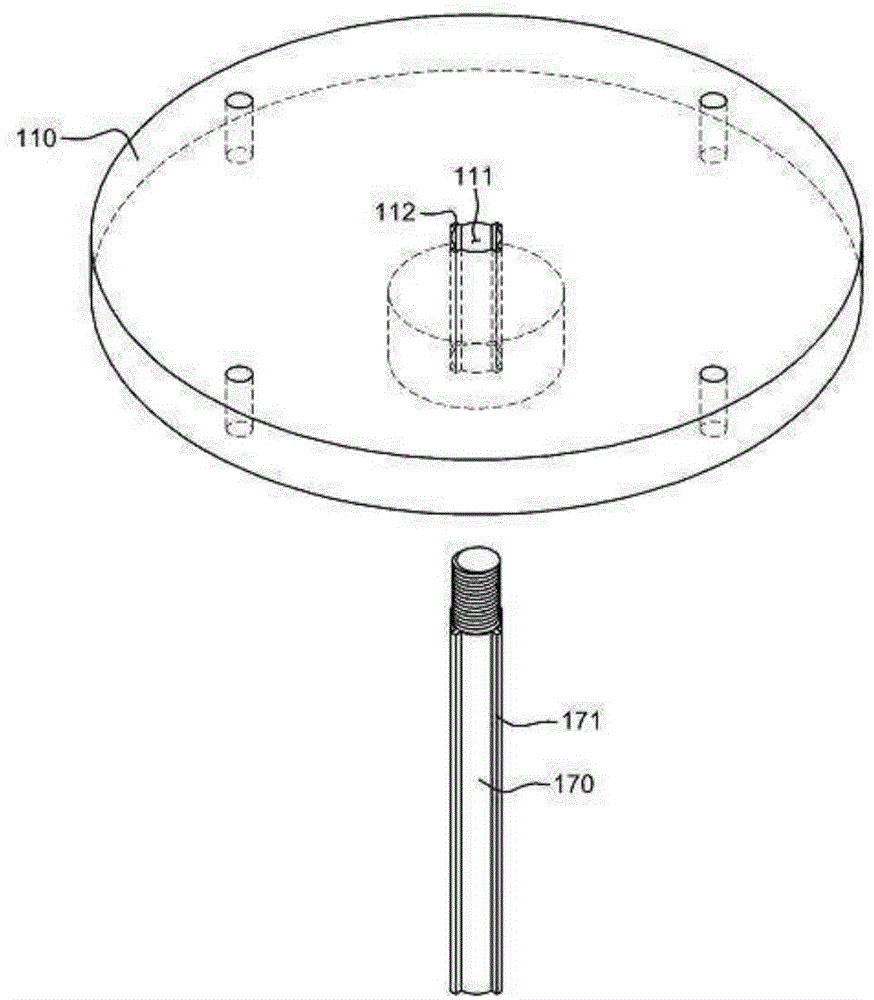

[0027] figure 1 To show a cross-sectional view of the structure of a centrifugal casting device according to a preferred embodiment of the present invention, figure 2 To show a sectional view of the sleeve structure according to the present invention, image 3 It is a perspective view showing the combined structure of the turntable and hydraulic ejector pin according to the present invention.

[0028] The centrifugal casting device according to the present invention has the following characteristics: the lower mold 140 provided at the lower part of the core (core) 200 is configured to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com