Coil-crossed moisture-proof cotton packaging method based on packaging film

A cotton and film layer technology, applied in the directions of packaging, wrapping paper, transportation and packaging, can solve the problems of moisture deterioration, difficult to distribute, affecting the quality of cotton storage, and achieve the effect of improving the storage period and being less prone to moisture deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

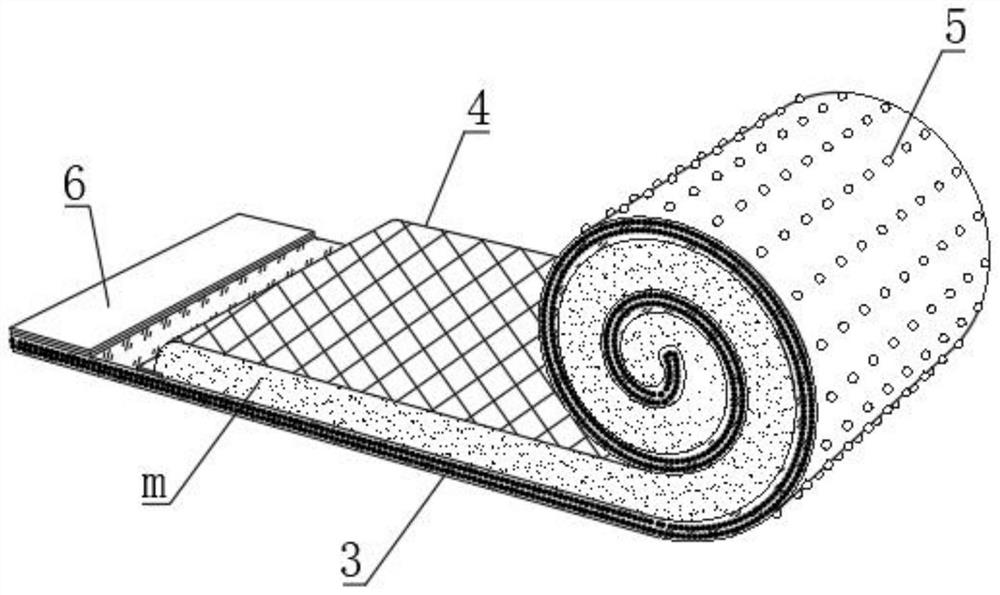

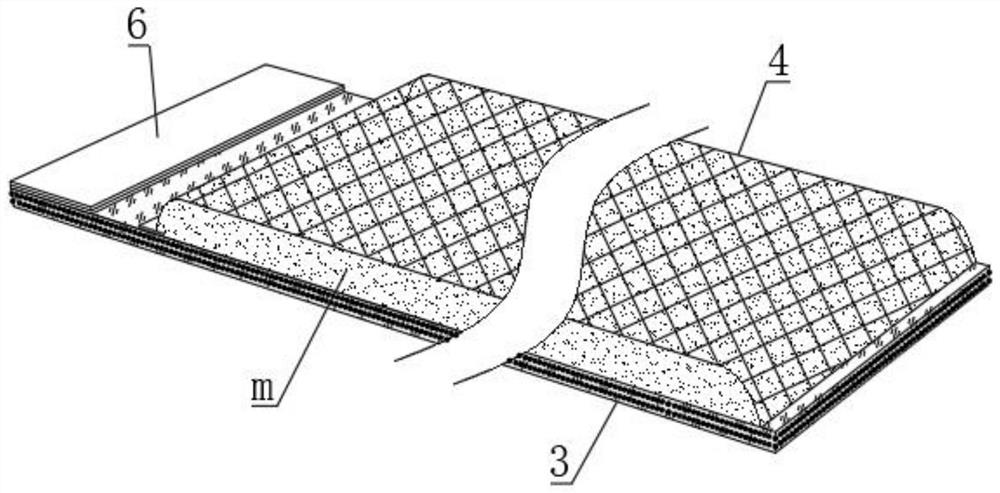

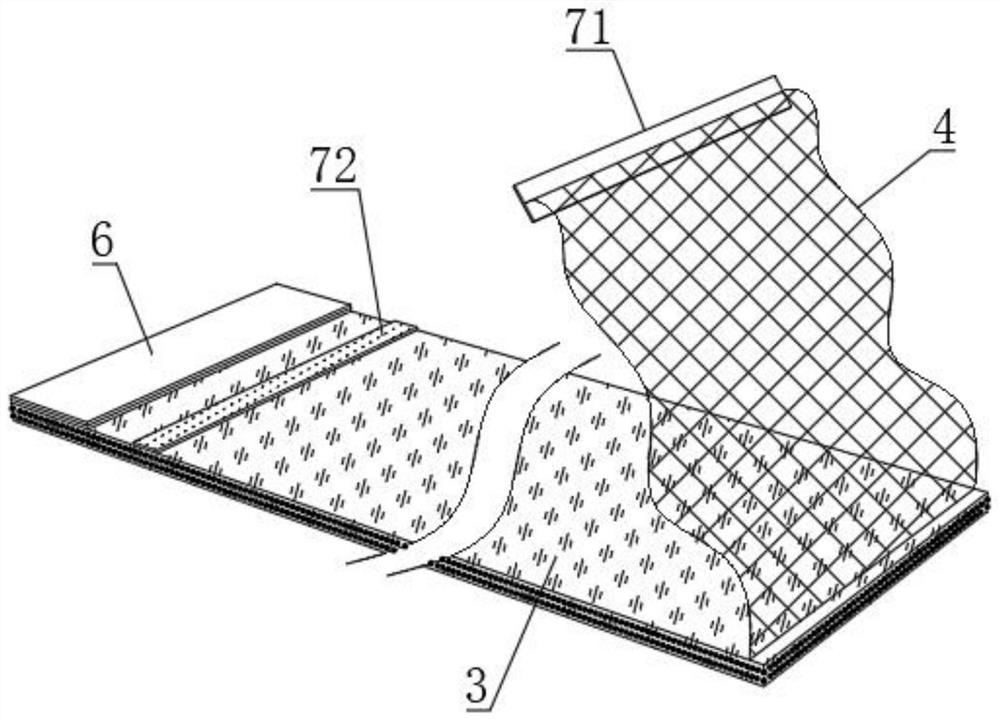

[0045] see Figure 1 to Figure 3 , a kind of winding moisture-proof cotton packaging method based on packaging film, comprising dehumidification packaging film, dehumidification packaging film includes single-sided hygroscopic film 3 and net cover 4, one end of single-sided hygroscopic film 3 and one end of net cover 4 are fixed Connected, the lower surface of the single-sided moisture-absorbing film 3 is provided with a plurality of evenly distributed moisture-absorbing pompoms 5, and the packaging method includes the following steps:

[0046] S1. Fully unfold the single-sided moisture-absorbing film 3 and spread it on a flat surface with its back facing down;

[0047] S2. Pile up the cotton to be packed on the upper surface of the single-sided hygroscopic film 3 and compact it to ensure that the upper surface of the cotton tends to be horizontal;

[0048] S3. Cover the net cover 4 on the upper surface of the cotton, and make the end of the net cover 4 adhere to the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com