An anti-cracking exterior wall coating for buildings

A technology for exterior wall coatings and construction, applied in the direction of polyester coatings, coatings, etc., can solve problems such as cracking, and achieve the effects of good water resistance, good cracking resistance, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

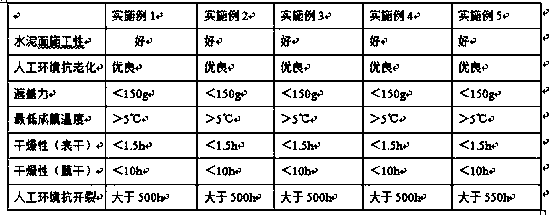

Examples

Embodiment 1

[0024] An anti-cracking exterior wall coating for buildings, which is formulated according to the following proportions: styrene-acrylic emulsion 25kg, methyl acrylate 12kg, acrylic modified alkyd resin 10kg, dimethyldichlorosilane 5kg, unsaturated polyester resin 5kg, bisphenol A diglycidyl ether 9kg, heavy calcium powder 1kg, sodium bentonite 2kg, sepiolite fiber 0.5kg, zinc oxide 1.5kg, magnesium stearate 5kg, triglycidyl isocyanurate 0.5kg, water 5kg, 0.3kg of diethylenetriamine, 1kg of other additives, the acid value of the unsaturated polyester resin is 110, and the epoxy value of bisphenol A diglycidyl ether is 0.48-0.5mol / 100g.

Embodiment 2

[0026] An anti-cracking architectural exterior wall coating, which is formulated according to the following proportions: styrene-acrylic emulsion 34kg, methyl acrylate 15kg, acrylic modified alkyd resin 15kg, dimethyldichlorosilane 3kg, unsaturated polyester resin 3kg, bisphenol A diglycidyl ether 7kg, heavy calcium powder 3kg, sodium bentonite 5kg, sepiolite fiber 1.5kg, zinc oxide 1kg, magnesium stearate 3kg, triglycidyl isocyanurate 0.3kg, water 10kg , 0.5kg of diethylenetriamine, 3kg of other additives, the acid value of the unsaturated polyester resin is 80, and the epoxy value of bisphenol A diglycidyl ether is 0.48-0.5mol / 100g.

Embodiment 3

[0028] An anti-cracking architectural exterior wall coating, which is formulated according to the following proportions: styrene-acrylic emulsion 27kg, methyl acrylate 14kg, acrylic modified alkyd resin 12kg, dimethyldichlorosilane 3kg, unsaturated polyester resin 5kg, bisphenol A diglycidyl ether 8kg, heavy calcium powder 1kg, sodium bentonite 5kg, sepiolite fiber 1.5kg, zinc oxide 1kg, magnesium stearate 5kg, triglycidyl isocyanurate 0.5kg, water 5kg , 0.4kg of diethylenetriamine, and 3kg of other additives. The acid value of the unsaturated polyester resin is 80, and the epoxy value of bisphenol A diglycidyl ether is 0.48-0.5 mol / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com