Reversible micro-fluidic chip clamp

A technology of microfluidic chips and fixtures, which is applied to manufacturing tools, workpiece clamping devices, etc., can solve the problems of inconvenient rotation and connection of microfluidic chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

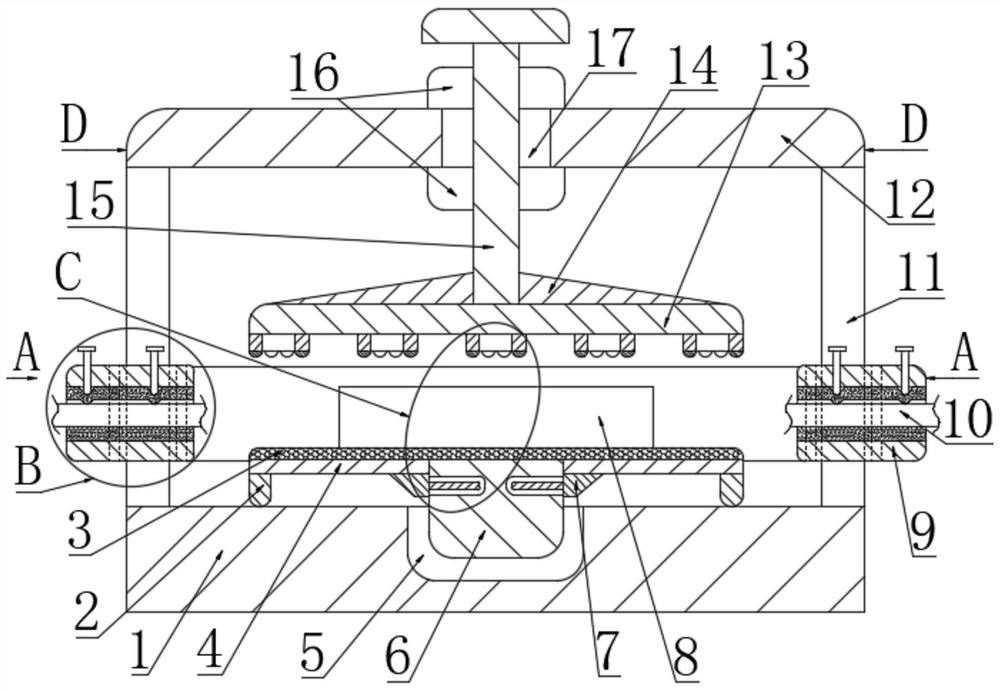

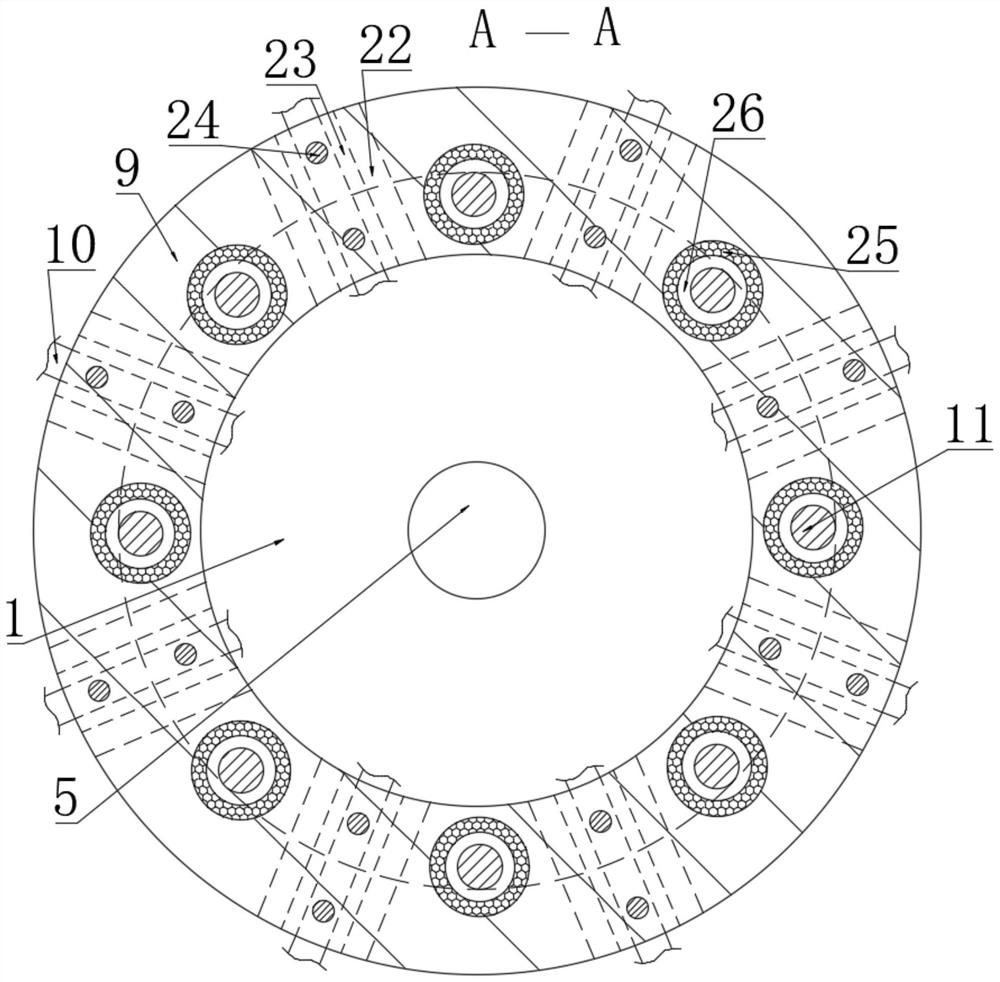

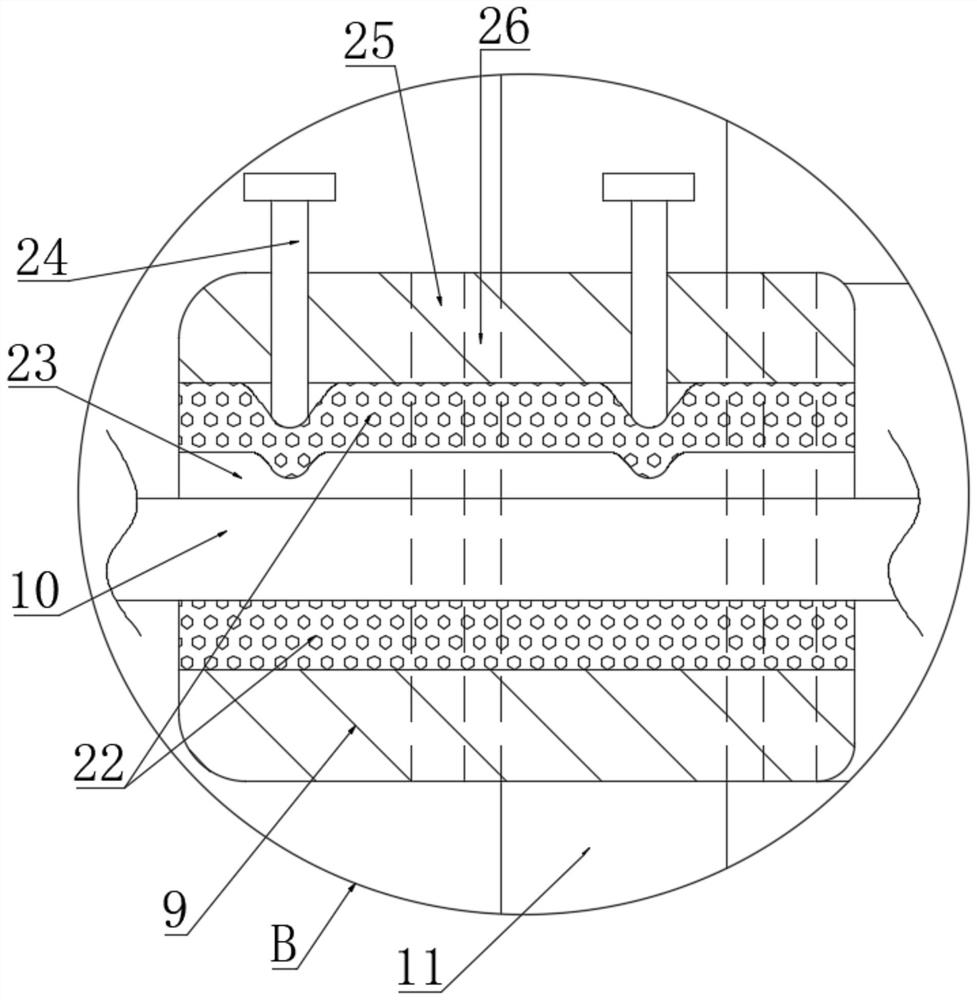

[0029] see figure 1 , figure 2 and Figure 6 , a reversible microfluidic chip fixture, including a bottom plate 1, the bottom plate 1 is a circular structure; the top of the bottom plate 1 is provided with a groove 5, and the groove 5 is a circular structure; the inside of the groove 5 is inserted with a rotary table 6, and the rotary table The height of 6 is not less than the depth of groove 5.

[0030] see figure 1 , figure 2 and Figure 6 , the rotary table 6 is rotatably connected to the bottom plate 1 through the groove 5, and is used to drive the microfluidic chip 8 to rotate, and adjust the angle of the connection between the microfluidic chip 8 and the fluid conduit 10; the side of the rotary table 6 is equipped with a support bar 4 , the support bar 4 is an elongated structure, the top of the support bar 4 is flush with the top of the turntable 6, the support bar 4 is parallel to the base plate 1, and the length of the support bar 4 is not greater than the radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com