Veneer mounting structure

A technology for installing structures and decorative panels, which is applied in building components, building structures, buildings, etc., can solve the problems that the installation direction of decorative panels is difficult to match the actual working conditions and the cost of decoration increases.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example:

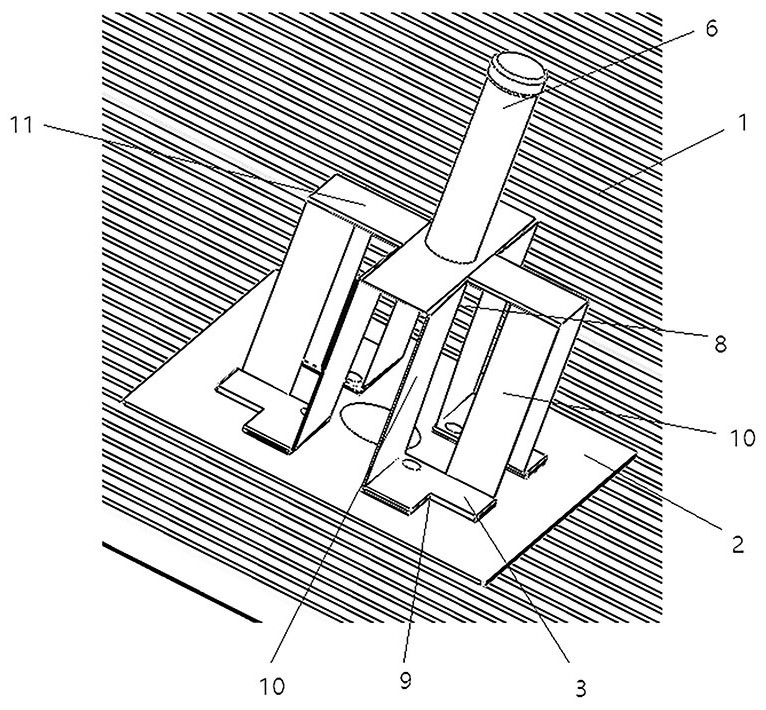

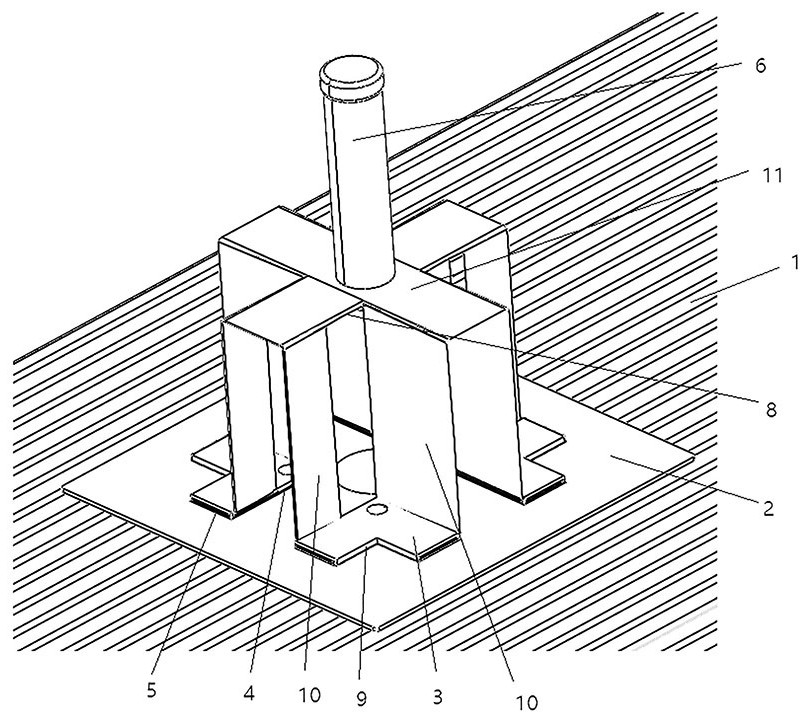

[0024] see Figure 1-2 , This embodiment provides a veneer installation structure, including a veneer 1, a mounting plate 2 and a hanging piece.

[0025] The decorative panel 1 is set horizontally, the mounting plate 2 is fixed on the upper surface of the decorative panel 1 by screws, the upper surface of the mounting plate 2 is provided with a connecting seat, the lifting piece is connected with the connecting seat, the upper end of the lifting piece is installed on the ceiling, and the lifting piece passes through The connecting seat hoistes the mounting plate 2 and the decorative panel 1 .

[0026] Specifically, the number of connecting seats is at least three, all connecting seats are arranged in a circular array, and the distance between two circumferentially adjacent connecting seats in the circular array is a constant value, and the hoisting parts are connected with all connecting seats in the circular array. Detachable connection.

[0027] Taking t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com