Push-button switch

A switch and button technology, which is applied in the field of retaining structure of terminals, can solve the problems of deterioration of installation performance, inclination of terminal circuit boards, and penetration of flux into housing 11, etc., and achieves the effect of simple structure and prevention of twisting and bending.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

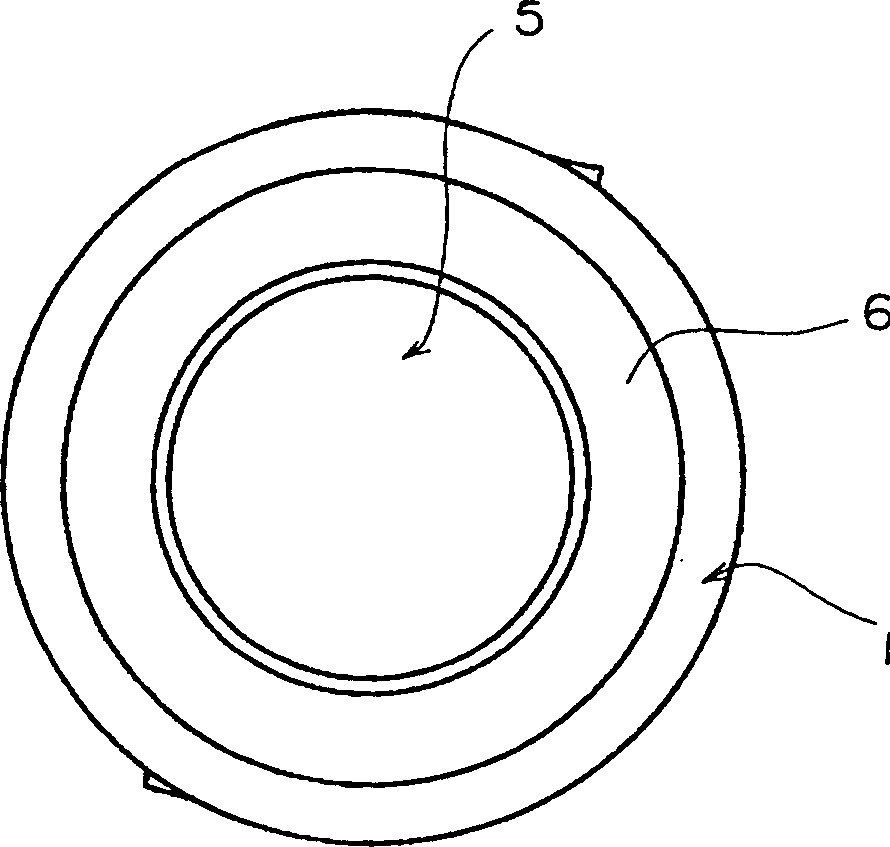

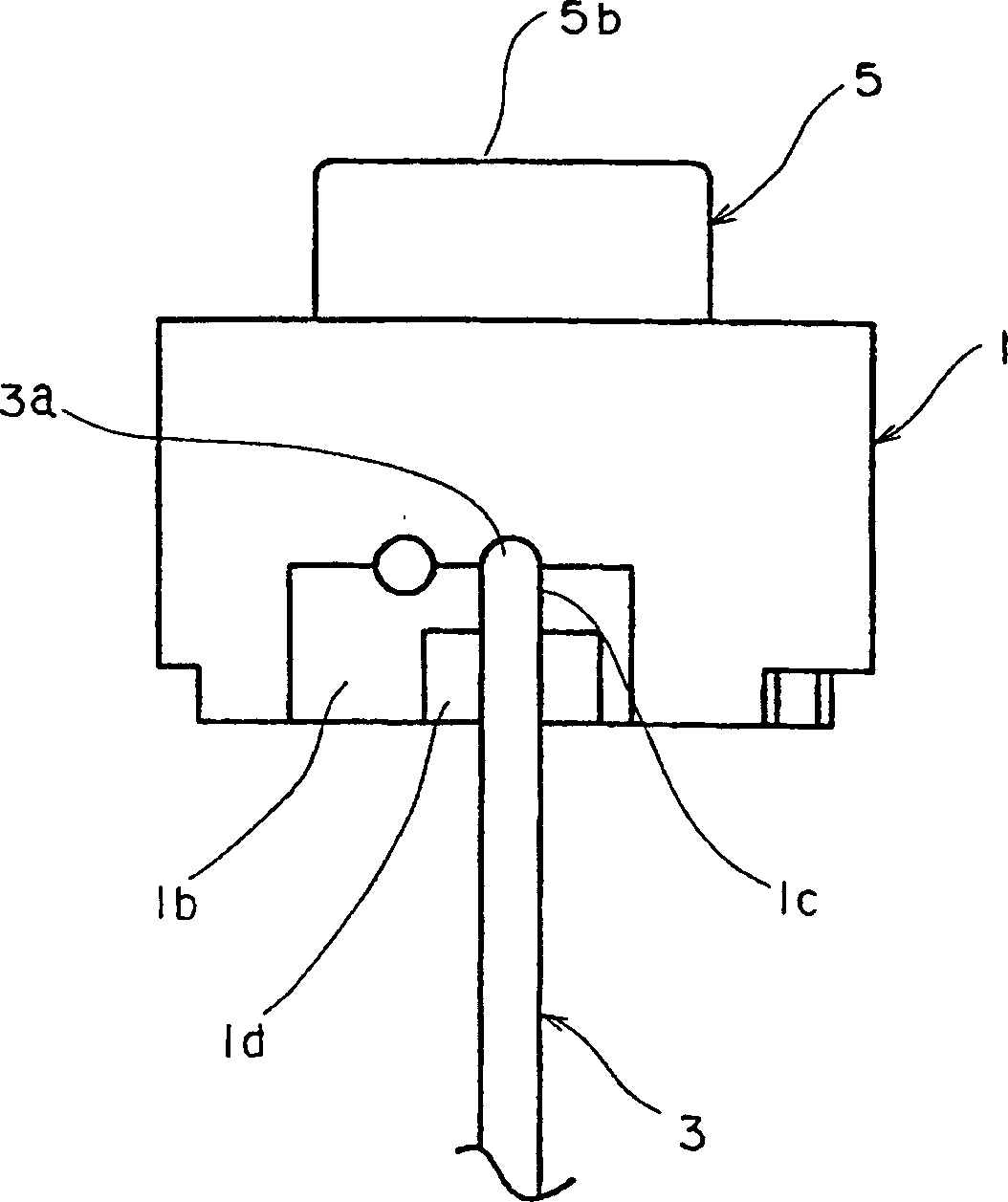

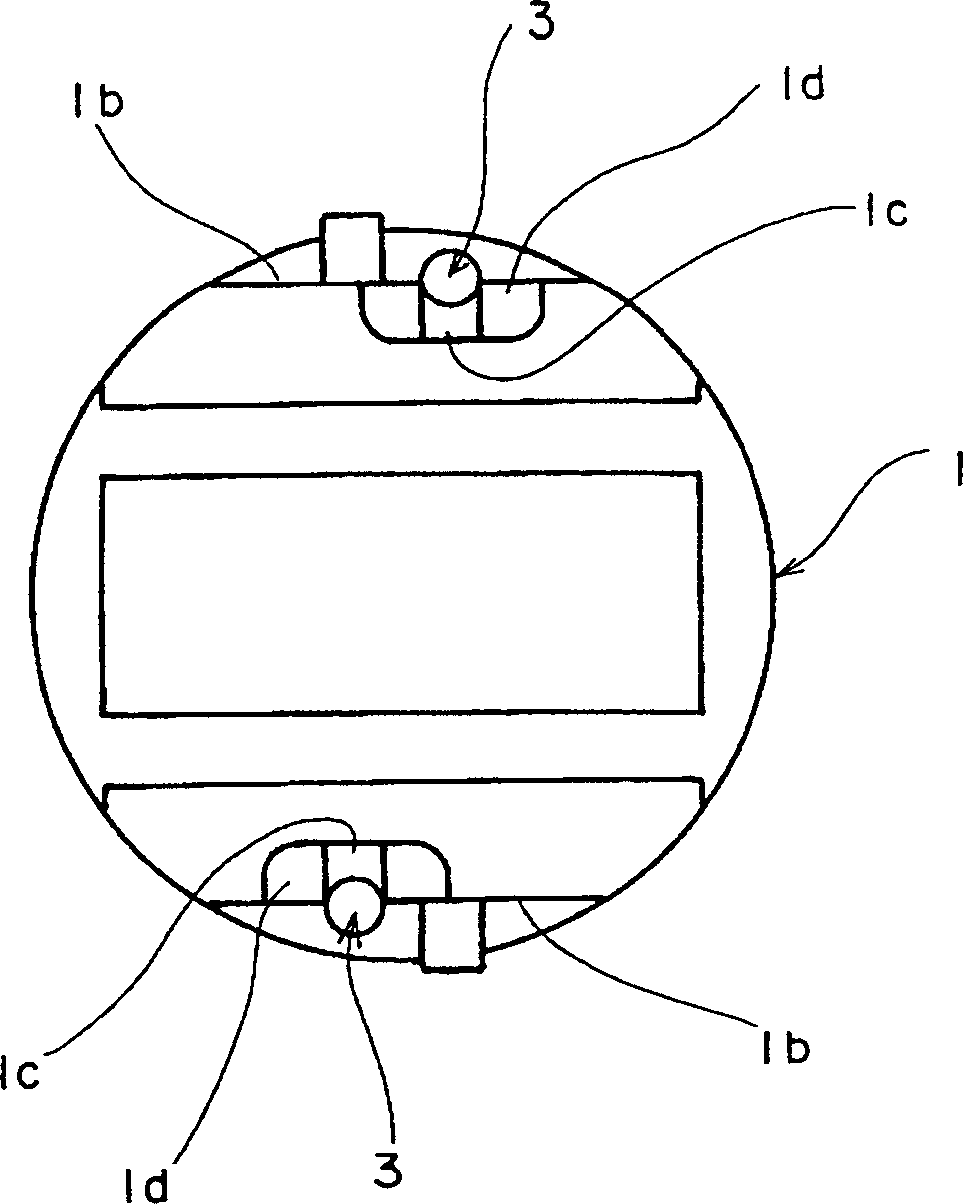

[0025] exist Figure 1 to Figure 6 Among them, the casing 1 is made of an insulating material such as synthetic resin and it has a bottomed box shape with an accommodating portion 1a therein. On the inner bottom surface of the accommodating portion 1a of the case 1, opposing fixed contacts 2, 2 composed of a pair of circular wires are arranged. The other ends of the fixed contacts 2, 2 protrude beyond the outer surface of the housing 1, so that the protruding free ends respectively form wirings connected to the circuit patterns of the electric circuit board, etc. not shown. Terminal 3. In addition, the connection terminal 3 is formed pendulously along the outer surface of the housing 1 and is bent into a Shaped curved portion 3a.

[0026] A pair of flat portions 1b on which the connection terminals 3 protrude are formed on the outer side of the housing 1 . On the flat portion 1b, a longitudinal groove 1c extending perpendicular to the bottom surface of the housing 1 from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com