Telescopic special equipment for crossing distribution network line

A special equipment and telescopic technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of time-consuming, labor-intensive, high cost, and difficult construction of new lines across operating lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

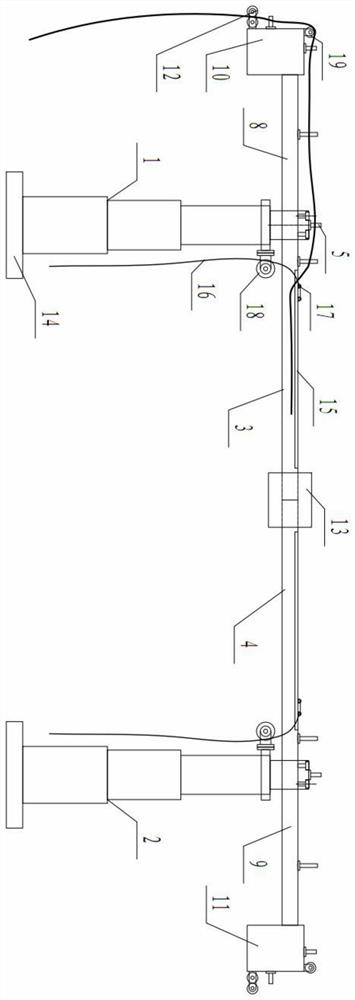

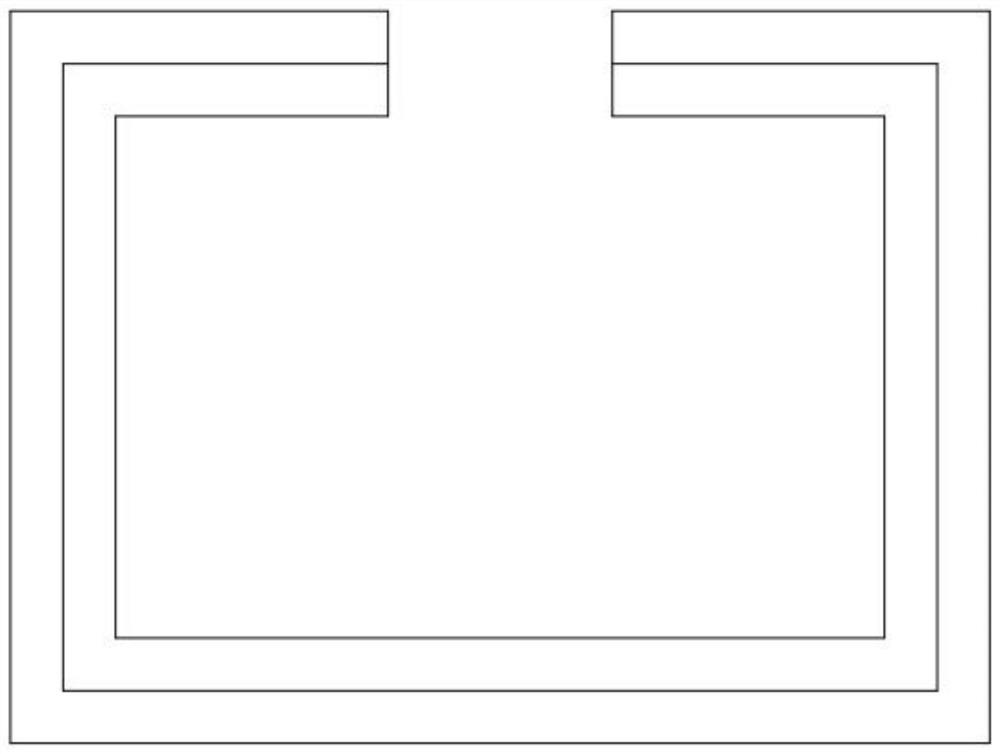

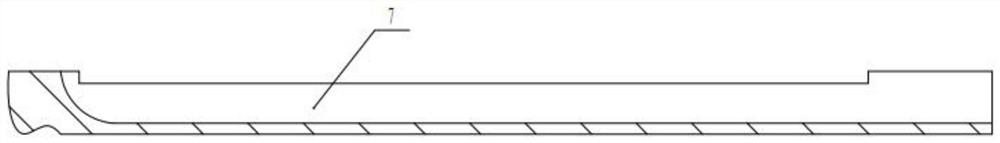

[0021] Embodiment 1: as Figure 1-Figure 5 As shown, a telescopic special equipment for crossing distribution network lines, including an insulated first hydraulic telescopic rod 1, a second hydraulic telescopic rod 2, a first cantilever rod 3 and a second cantilever rod 4, the first cantilever rod 3 and the second cantilever rod Two cantilever rods 4 are respectively connected to the upper ends of the first hydraulic telescopic rod 1 and the second hydraulic telescopic rod 2, the free ends of the first cantilever rod 3 and the second cantilever rod 4 can be docked, and the first hydraulic The top of the telescopic rod 2 is provided with a wire clip 5, and a U-shaped wire notch 6 is arranged on the wire clip 5, and the upper sides of the first cantilever rod 3 and the second cantilever rod 4 are provided with two wires that can be connected. Through slot 7, the upper cover of the wire conveying through groove 7 is closed with two cover plates 15 that are separated, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com