Vertical sliding rail type steel structure machining platform

A processing platform and sliding rail technology, applied in the field of steel structures, can solve the problems of difficulty in ensuring accuracy and product quality, and achieve the effects of improving flexibility, versatility and convenience in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be described in detail below through specific examples, but the scope of the present invention is not limited by these examples.

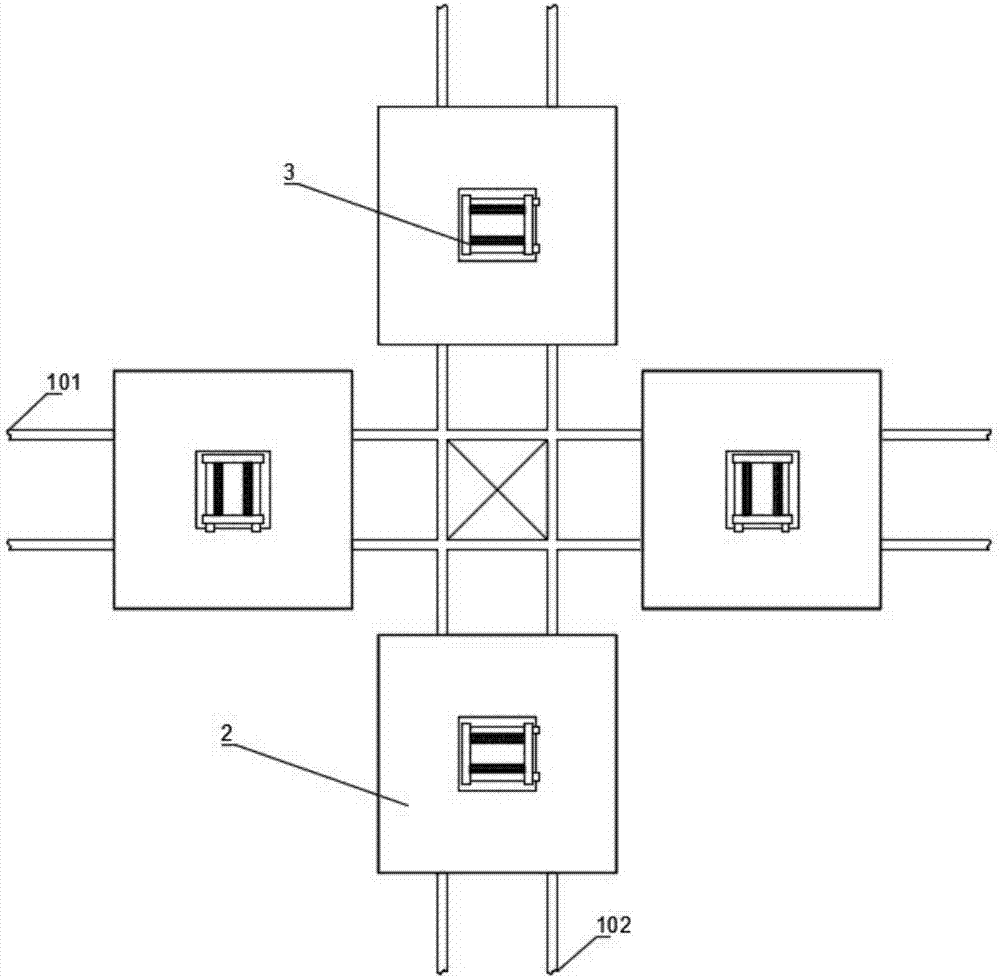

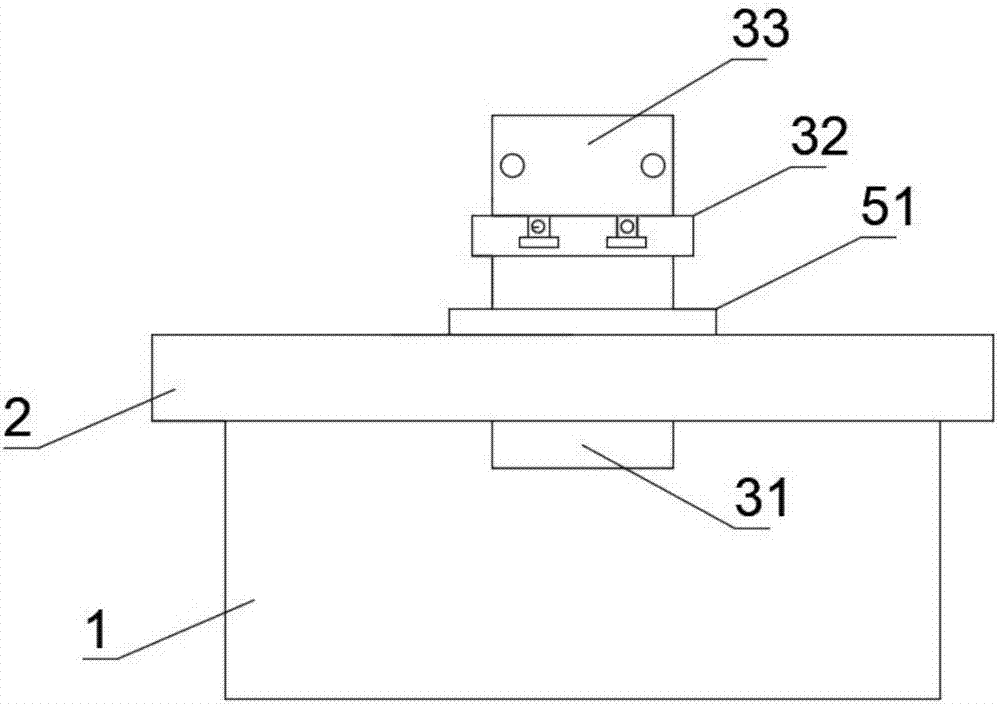

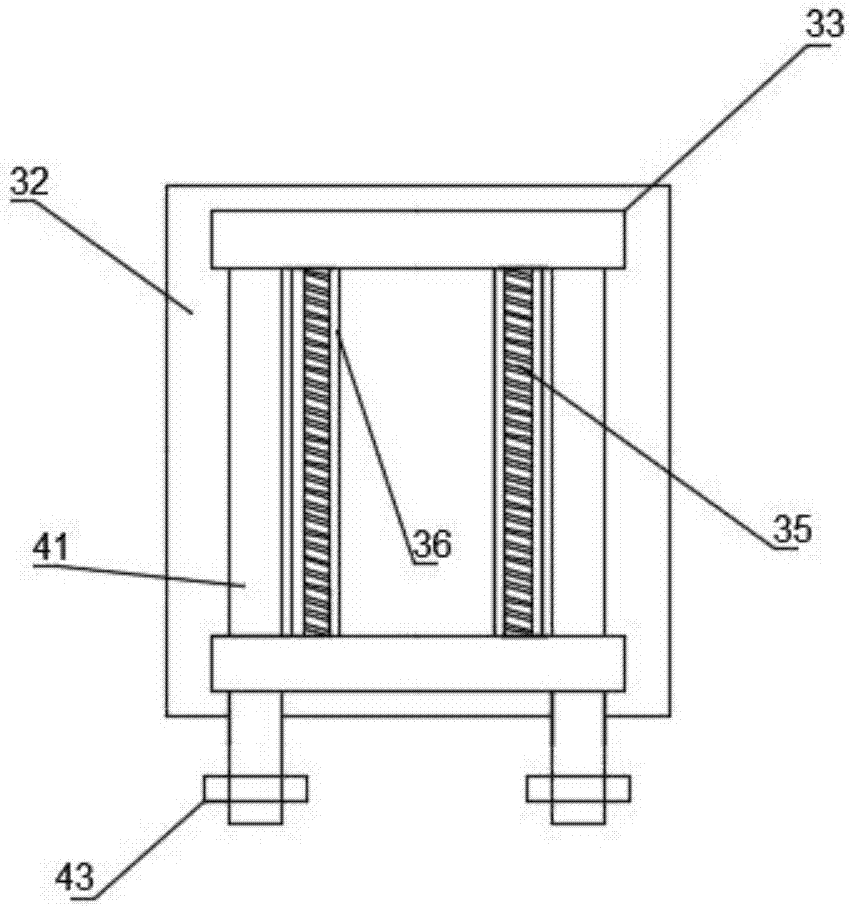

[0013] Such as Figures 1 to 3 As shown, this embodiment provides a vertical slide rail type steel structure processing platform, including a slide rail and a clamping platform; 102; two clamping platforms are movably installed on the horizontal slide rail 101 and the longitudinal slide rail 102; the clamping platform includes a base 1, a table top 2 and a clamping mechanism 3; the bottom of the base 1 slides through a chute Installed on the slide rail; the table top 2 is arranged on the top of the base 1, and the center of the table top 2 is provided with a mounting hole; the clamping mechanism 3 includes a mounting column 31, a mounting plate 32 and two clamping arms 33; clamping The mechanism 3 is rotatably installed in the mounting hole on the table top 2 through the mounting column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com