Automatic spring piece assembling mechanism

An automatic assembly and spring leaf technology, which is applied in the direction of workpiece clamping devices, hand-held tools, manufacturing tools, etc., can solve the problems of narrow space, push rods that cannot achieve high thrust, precise push, and complex shell structures. To achieve the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

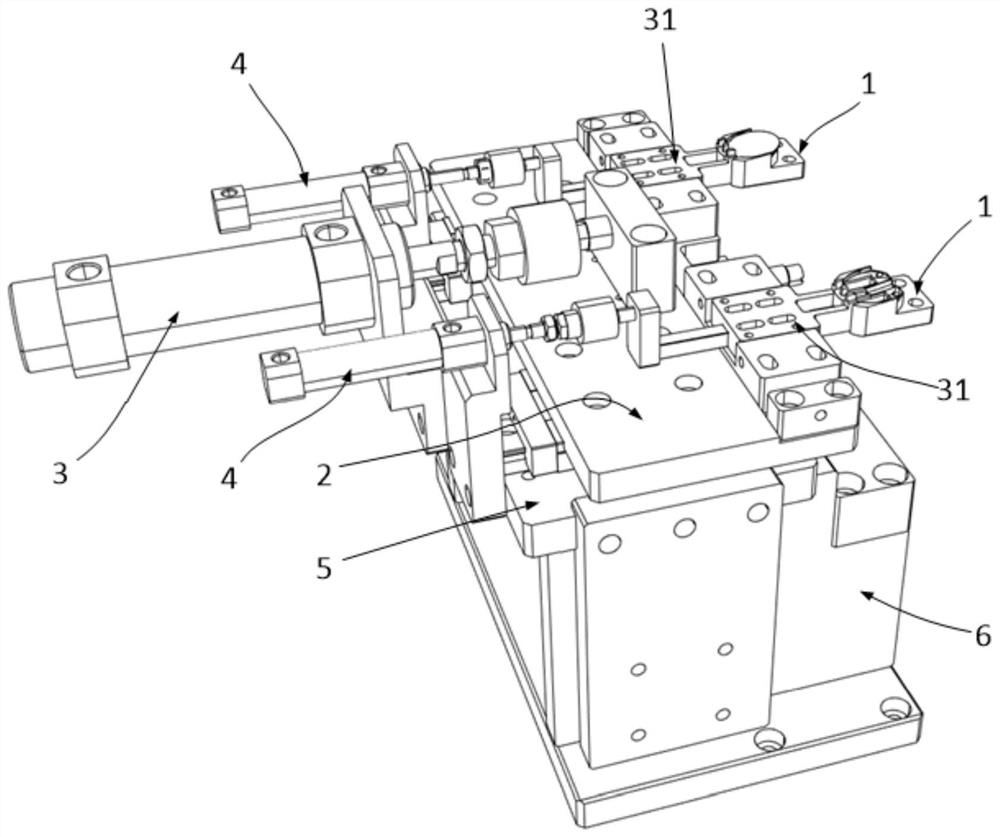

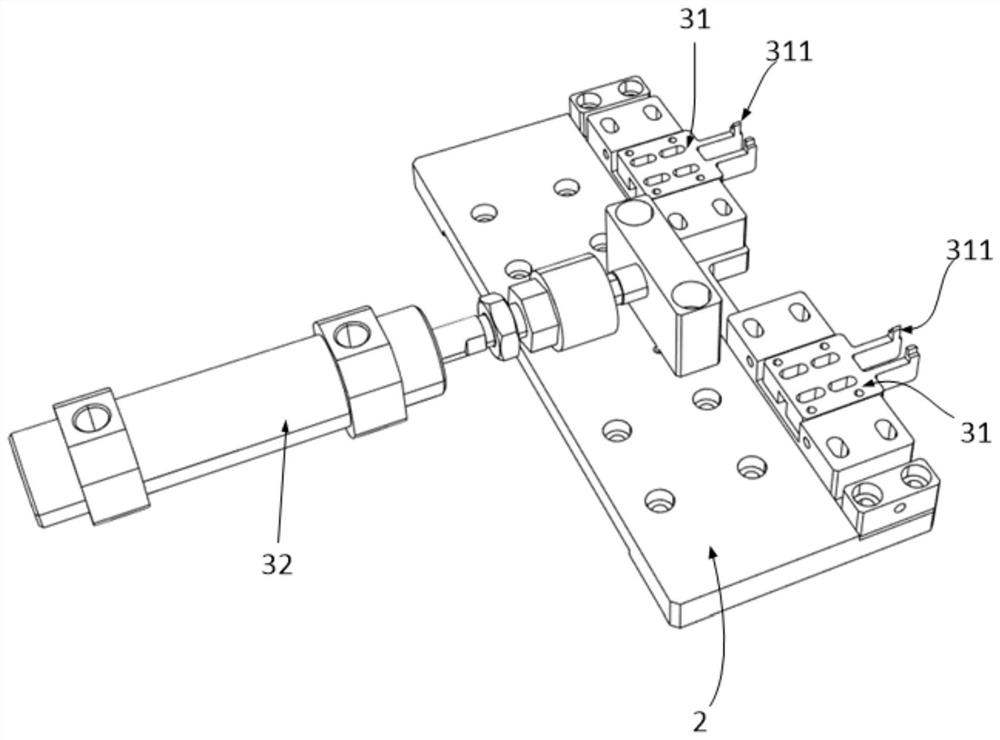

[0067] This embodiment provides an automatic spring assembly mechanism, such as Figure 1-5 shown, including:

[0068] The support seat 1 has a spring sheet slot 11 for placing the spring sheet to be installed;

[0069] The first push mechanism 3 includes a first push rod 31 and a first drive member 32, and the first push rod 31 can move toward the support base 1 driven by the first drive member 32;

[0070] The second push mechanism 4 includes a second push rod 41 and a second drive member 42, and the second push rod 41 can move toward the support base 1 driven by the second drive member 42;

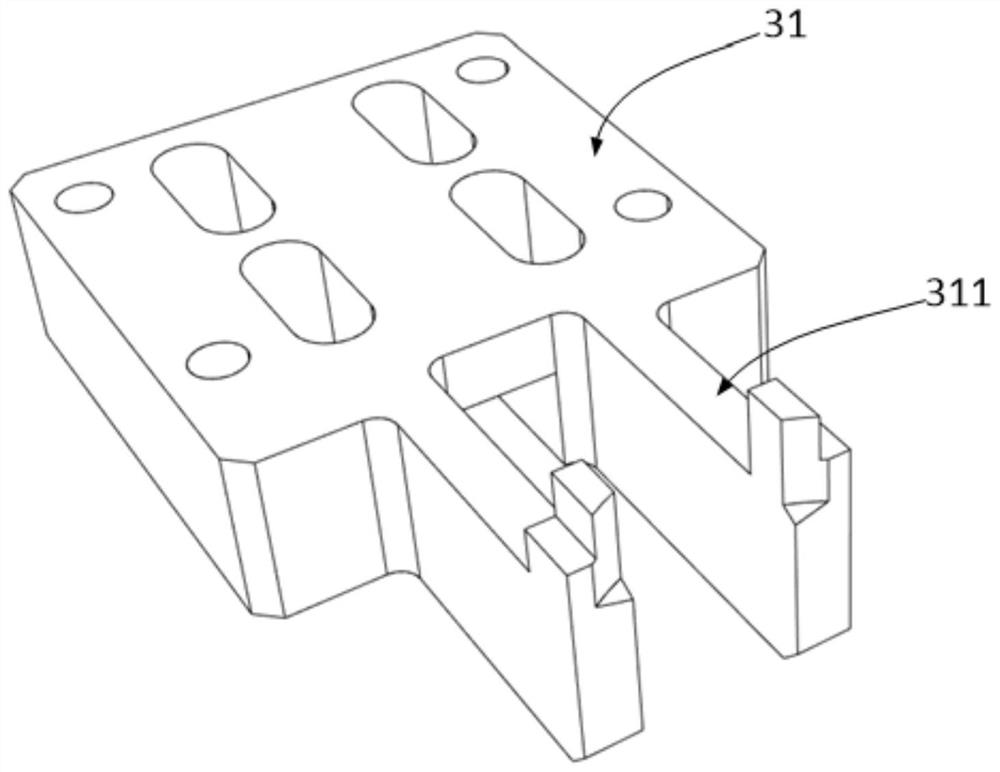

[0071]The end of the first push rod 31 has a push fork 311, and one side of the support seat 1 has a gap 12 for the push fork 311 to extend into; the second push rod 41 includes a push head 411, a guide rod 412, the pushing head 411 is aligned with the middle of the pushing fork 311, and the support base 1 has a slide groove 13 for the moving of the pushing head 411, and the pushing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com