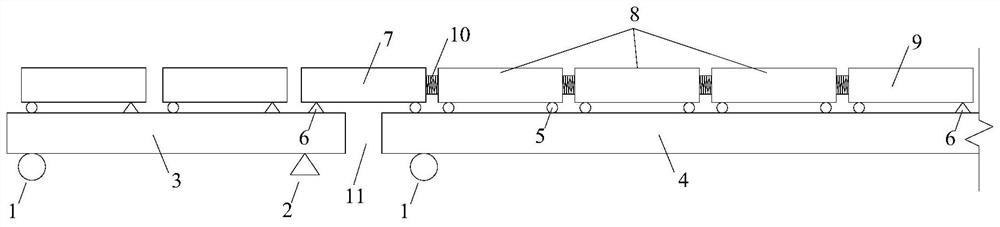

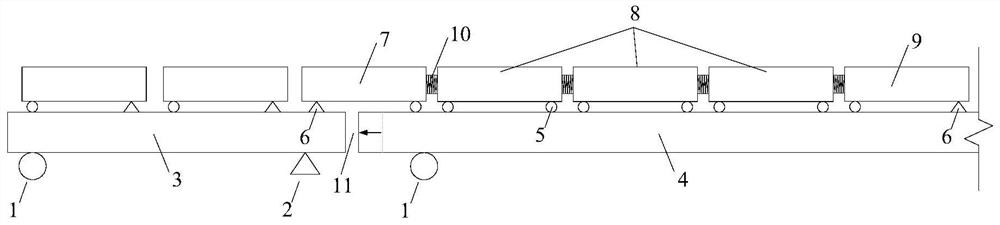

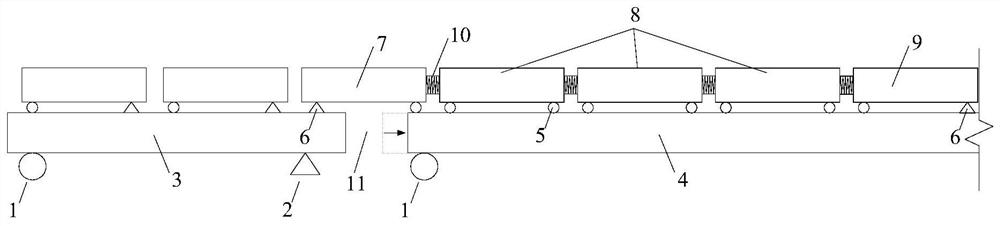

Large-span bridge beam end telescopic structure suitable for high-speed maglev traffic

A telescopic structure and large-span technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as difficult gap control, achieve good force transmission performance, solve stator gap overrun, and ensure longitudinal stability and displacement consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Taking the main bridge with a temperature span of 200m as an example, the design beam gap is 200mm, and the maximum temperature change range of the beam body affected by the external environment is ±20°C. The maximum expansion and contraction of the main bridge end affected by temperature is ±40mm, and the variation range of the beam gap is 160mm~240mm. The stator clearance requirement of 90~100mm at the joint position between the main bridge and the approach bridge cannot be met, and a telescopic structure at the end of the beam needs to be installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com