Mortise and tenon type scaffold inclined strut system

A scaffolding and mortise-and-tenon technology, which is applied in the field of mortise-and-tenon scaffolding brace system, can solve the problems that tenon-and-tenon scaffolding cannot become a complete system independently, and it is inconvenient to promote and use, so as to achieve small deformation, low cost, The effect of reliable self-locking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

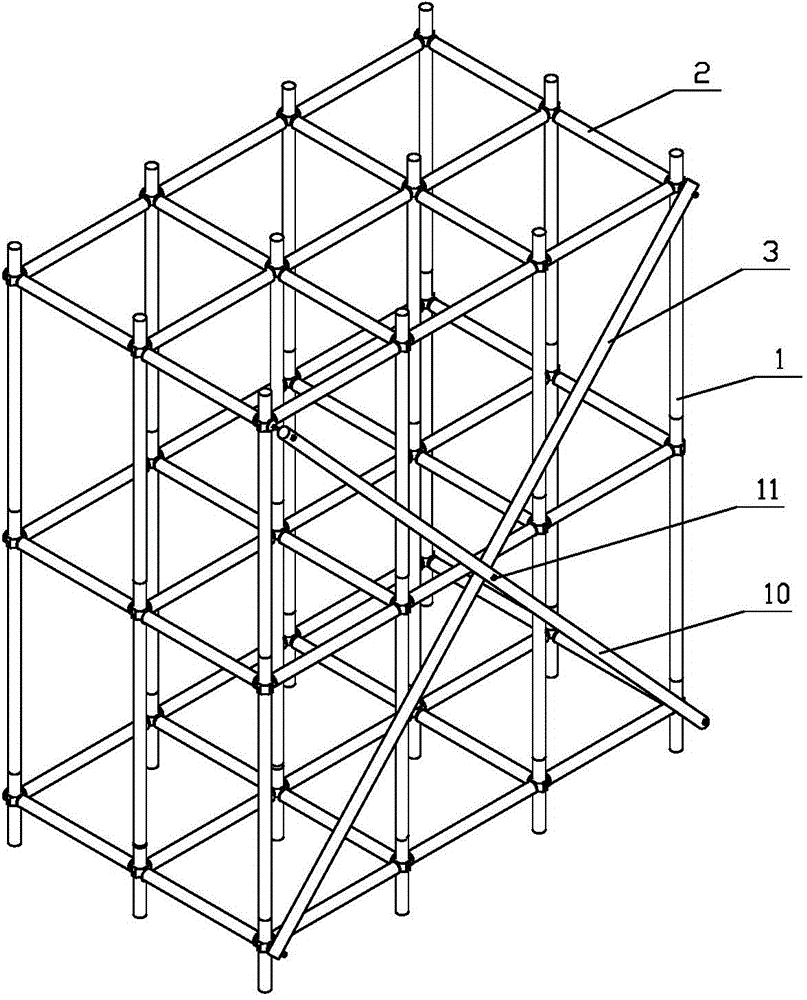

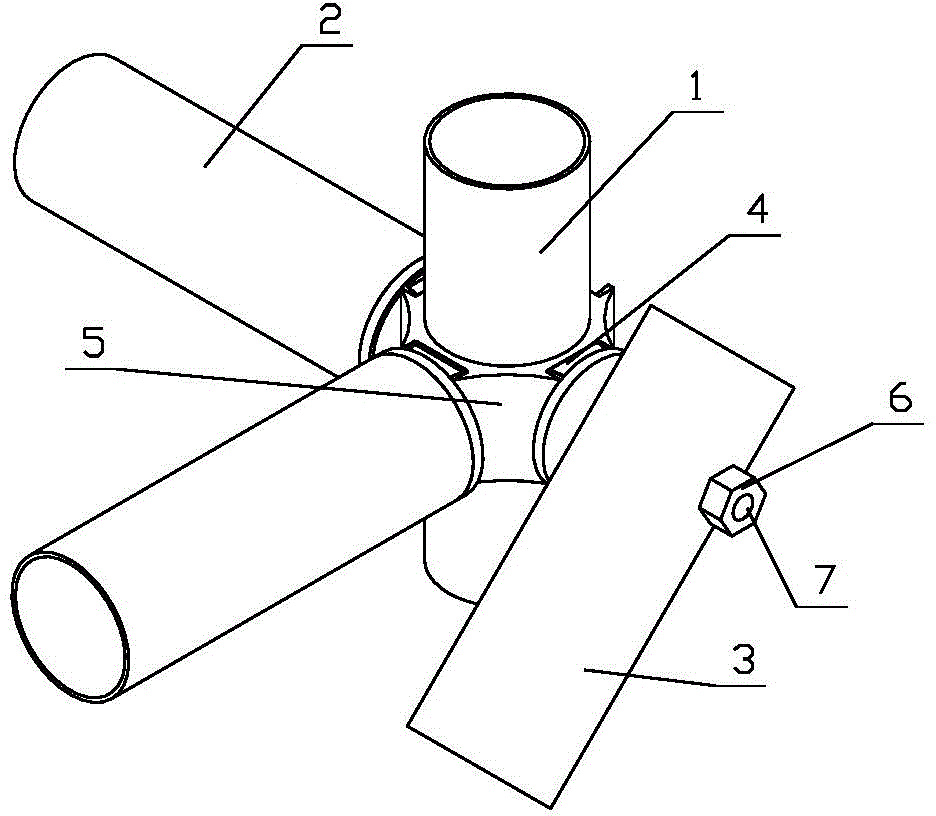

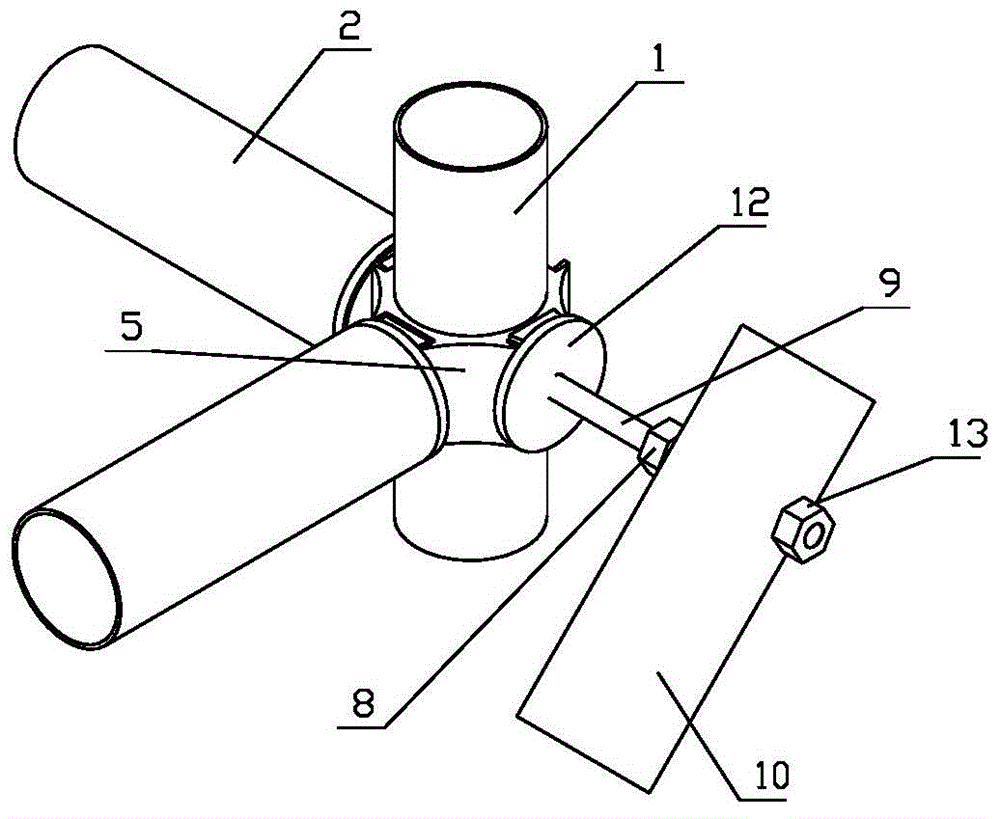

[0023] see Figure 1 to Figure 10 , a mortise-and-mortise scaffolding bracing system for mortise and tenon scaffolding, the mortise and tenon scaffold is composed of a horizontal bar 2 with a mortise head and a vertical bar 1 with a central mortise socket 5 .

[0024] The above-mentioned mortise and tenon scaffolding brace system includes a short screw brace 3 and a long screw brace 10 intersecting it. The long screw brace 10 is located outside the short screw brace 3 .

[0025] The upper and lower ends of the short screw connected to the brace 3 are penetrated with a short screw 7 perpendicular to it, and the inner end of the short screw 7 is fixed with a tenon I4, and the tenon I4 is assembled in the corresponding central mortise socket 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com