Rotational flow spillway tunnel for reducing flow velocity of outlet of rotational flow tunnel

A flood discharge tunnel and flow velocity technology, which is applied in hydroelectric power stations, coastline protection, sea area engineering, etc., can solve problems such as turbulence and corrosion of the diversion tunnel outlet flow state, reduce the water surface height difference, weaken the backwater phenomenon, and improve The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

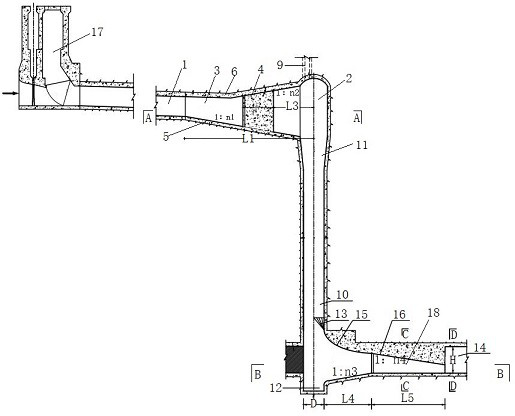

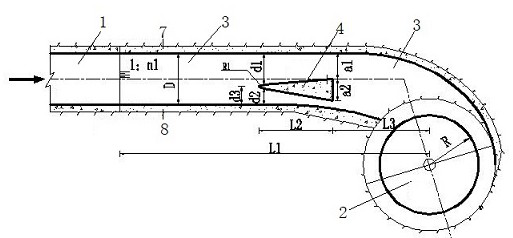

[0026] In order to overcome the problems of severe corrosion of existing diversion tunnels and disordered outlet flow state, the present invention provides such Figure 1-5 Shown is a swirl flood discharge tunnel that reduces the flow velocity at the outlet of the swirl tunnel. The present invention adopts the expansion connecting section to reduce the flow velocity at the bottom of the flood discharge tunnel, and uses the diversion pier to improve the flow state of the water flow, so as to ensure that the inner wall of the diversion tunnel will not be damaged. Excessive water erosion improves the service life of the diversion tunnel.

[0027] A swirl flood discharge tunnel that reduces the flow velocity at the outlet of the swirl tunnel, comprising a discharge sluice chamber 17, a diversion tunnel 1, a vortex chamber 2, a vertical shaft 10, an expansion connecting section, a stilling pool 12 and a diversion tunnel 14. The upstream of the diversion tunnel 1 is connected to the...

Embodiment 2

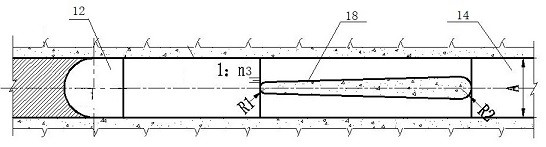

[0030] Based on the basis of Example 1, in this embodiment, preferably, the expansion connecting section includes a vertical section 13, a turning section 15 and a slope section 16, and the vertical section 13 and the slope section 16 Connected by the turning section 15, the width of the side wall of the turning section 15 and the pressure slope section 16 is the same as the width A of the diversion tunnel 14; the vertical section 13 transitions gradually from a semicircle of the shaft to a body shape in which the outside is a round arch and the inside is a straight line; The top arch of the turning section 15 is based on the end of the vertical section 13 as the starting point, and transitions to the starting point of the pressure slope section 16 in the form of a 1 / 4 ellipse major axis turning, wherein the ellipse equation is , a, b are determined according to the width A of the diversion tunnel, and the value of a is (1~3)A, and the value of b is (0.3~1)a; the bottom of the...

Embodiment 3

[0044] Based on the basis of embodiment 1 or 2, in the present embodiment, preferably, the thickness of the side wall-7 is 50cm; the width D of the bottom plate 5 is 680cm, the slope ratio of the bottom plate 5 is 1:7.4, and the slope ratio of the top arch 6 slope section is 1:8.6, the radius R of the vortex chamber 2 is 500cm, the distance a1 between the backwater surface and the side wall-7 of the transition section 3 is 300cm, the width a2 of the backwater surface is 300cm, the arc radius R1 of the water-facing surface is 150cm, and the side wall-7 of the water-facing surface The distance between the first wall 7 is d1 is 410cm, the distance d2 between the second side of the water-facing surface and the second side wall 8 is 195cm, the distance between the central axis of the water-facing surface and the second side wall 8 is d3, which is 240 cm, and the bottom plate is 5 The distance between the slope point and the center line of the vortex chamber 2 is L1, which is 4800cm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com