Local maintenance method for furnace bottom of flash furnace

A flash furnace and furnace bottom technology, used in furnace, lining repair, furnace components and other directions, can solve the problems of high economic cost, difficult to remove furnace bottom, time-consuming and laborious, etc., to reduce maintenance difficulty, reduce copper infiltration risk, The effect of ensuring the quality of masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

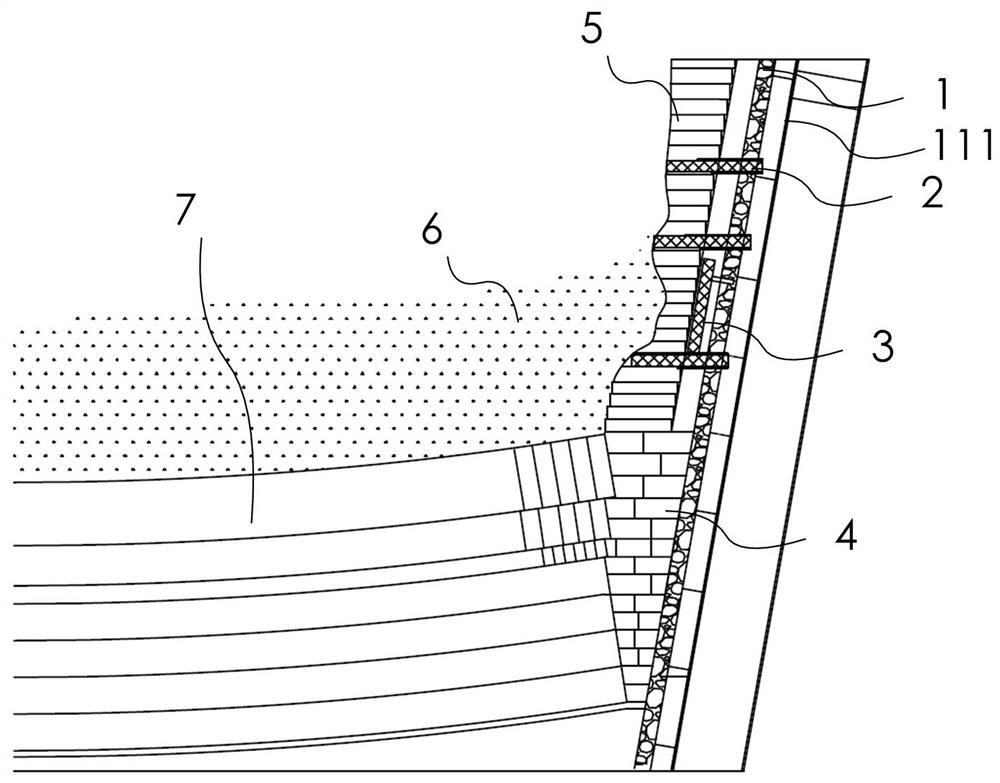

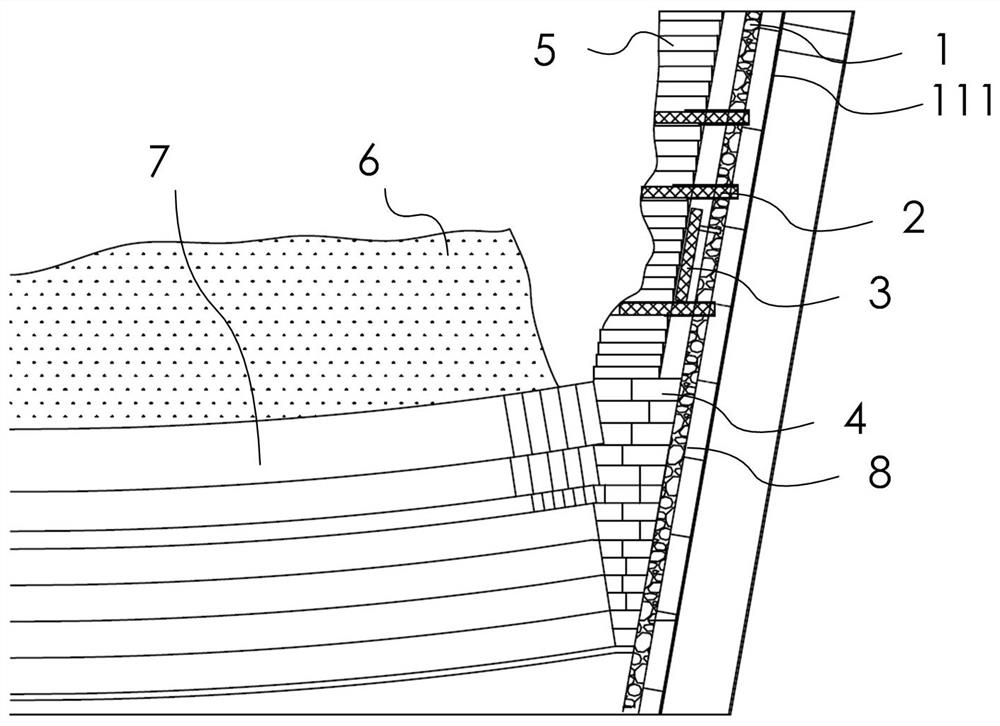

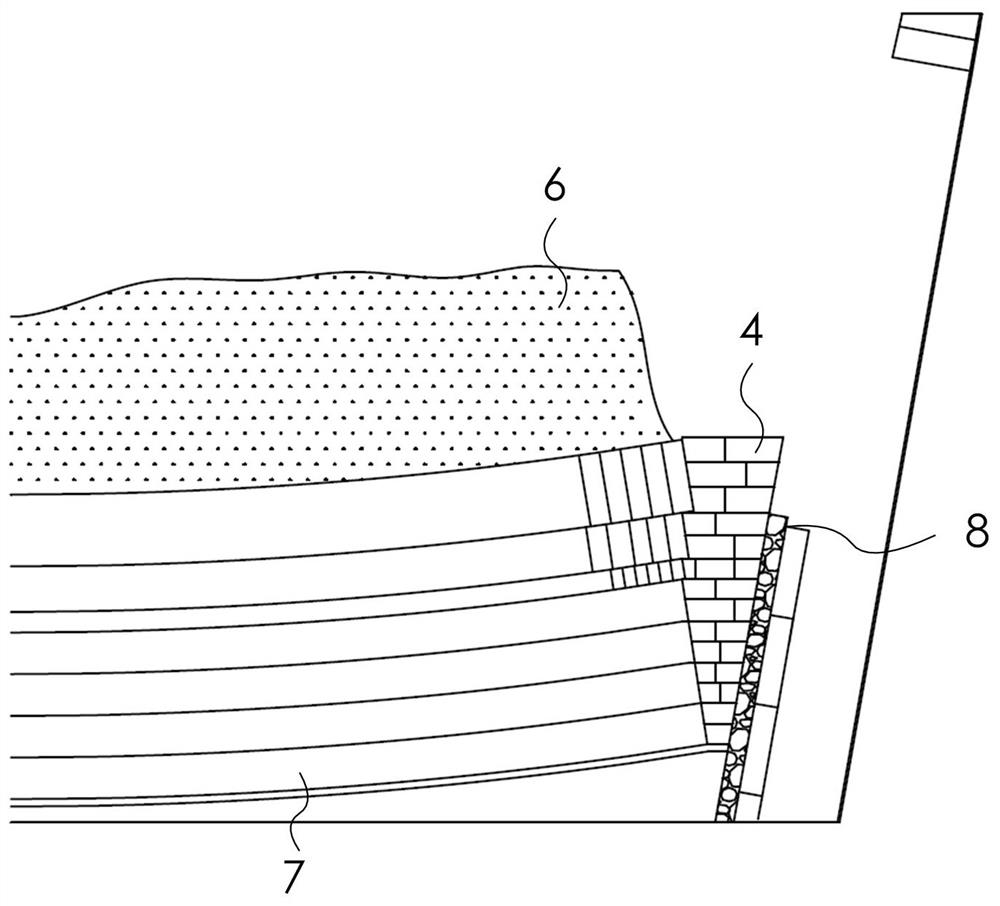

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0027] Such as Figures 1 to 7 Shown, the local overhaul method of this flash furnace bottom of the present invention, the steps are as follows:

[0028] S1, build a support frame;

[0029] S2. Directly dismantle supporting objects such as steel plates, copper water jackets, steel beams and other supporting objects of the furnace wall shell of arch foot bricks in the area to be replaced, and remove them to the position below the arch foot bricks;

[0030] S3, remove the refractory bricks of the furnace wall above the area;

[0031] S4, remove the damaged arch brick 4;

[0032] S5, remove the slagging 6 with the free surface;

[0033] S6. Replace the arch foot brick 4.

[0034] When dismantling the 6 slagging places, the horizontal distance from the arch brick 4 is 300mm, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com