Multi-specification rotary intelligent vending machine and method thereof

An intelligent vending machine, a rotary technology, applied in the directions of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., can solve the problem of unfavorable utilization. space etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following is attached Figure 1-8 The application is described in further detail.

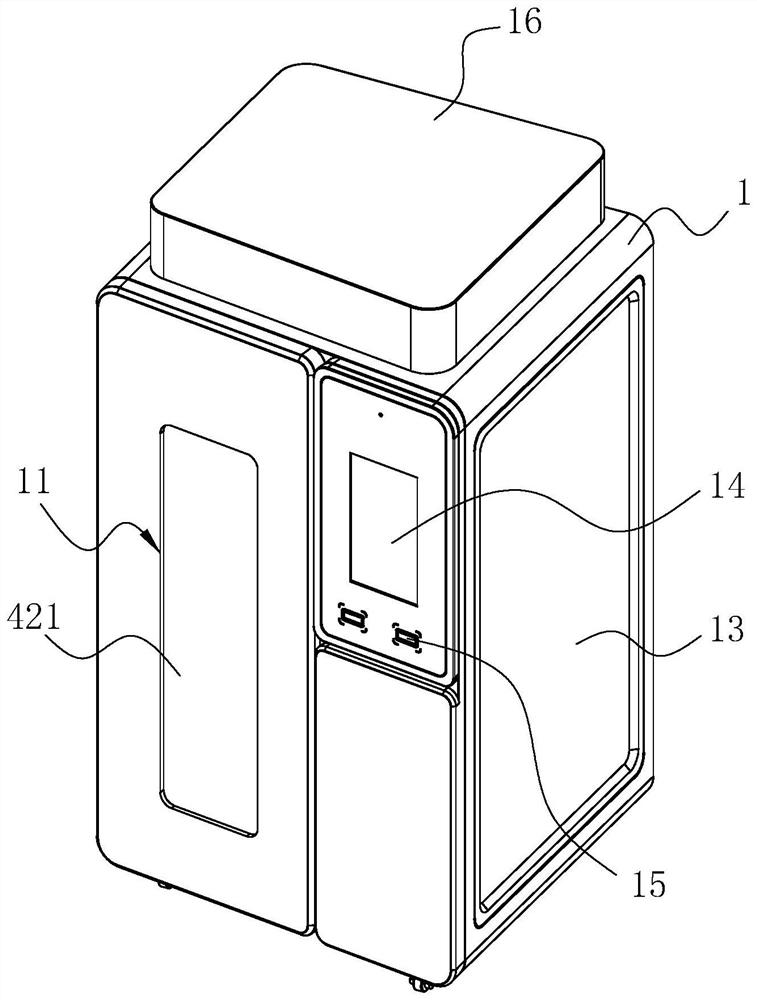

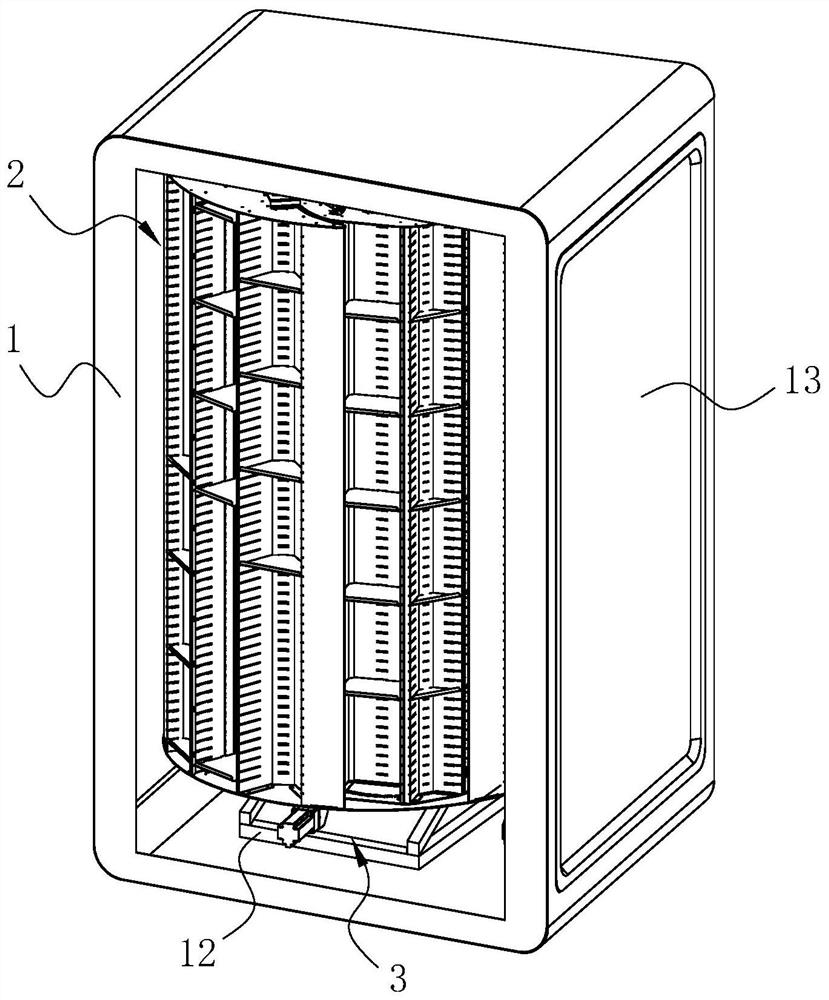

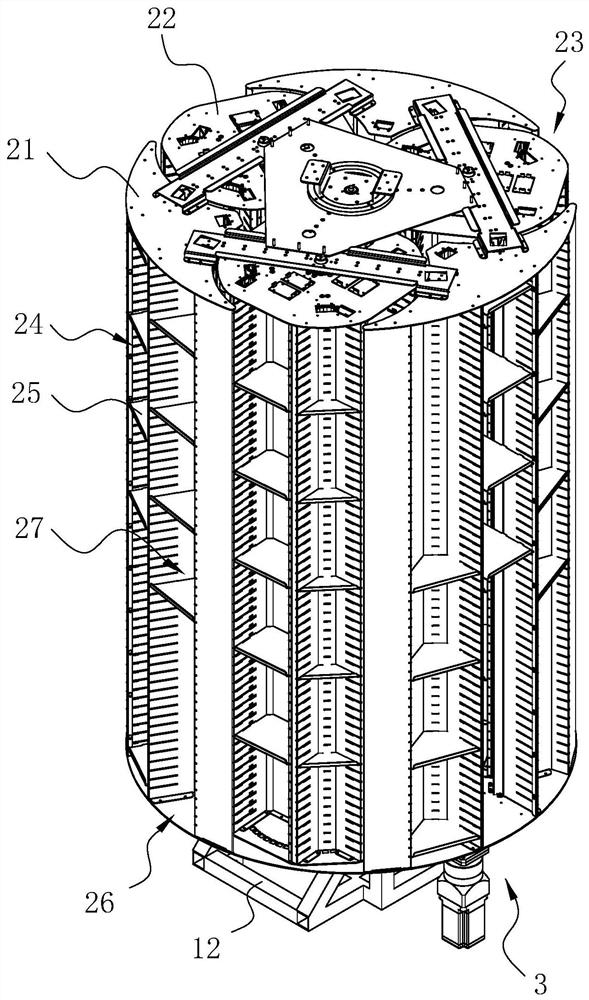

[0048] The embodiment of the present application discloses a multi-standard rotary intelligent vending machine. refer to figure 1 with figure 2 , The multi-standard rotary intelligent vending machine includes a cabinet body 1. The cabinet body 1 is in the shape of a square prism as a whole, and a square light box 16 is arranged on the top, and four universal wheels capable of self-locking are installed at the four corners of the bottom. The cabinet body 1 is built with a cargo storage mechanism 2, a cargo rack driving mechanism 3 for driving the cargo storage mechanism 2 to rotate, a door opening mechanism 4, a cargo grid scanning mechanism 5, and a control system. The control system is electrically connected with the cargo rack driving mechanism 3, the door opening mechanism 4 and the cargo grid scanning mechanism 5, and is used to control the rotation of the cargo rack driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com