A vertical ultrasonic cleaning machine for anti-sensitivity oral liquid bottle

A technology of ultrasonic wave and cleaning machine, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of low cleaning efficiency, labor and time consumption, etc., and achieve the effect of automatic liquid drainage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

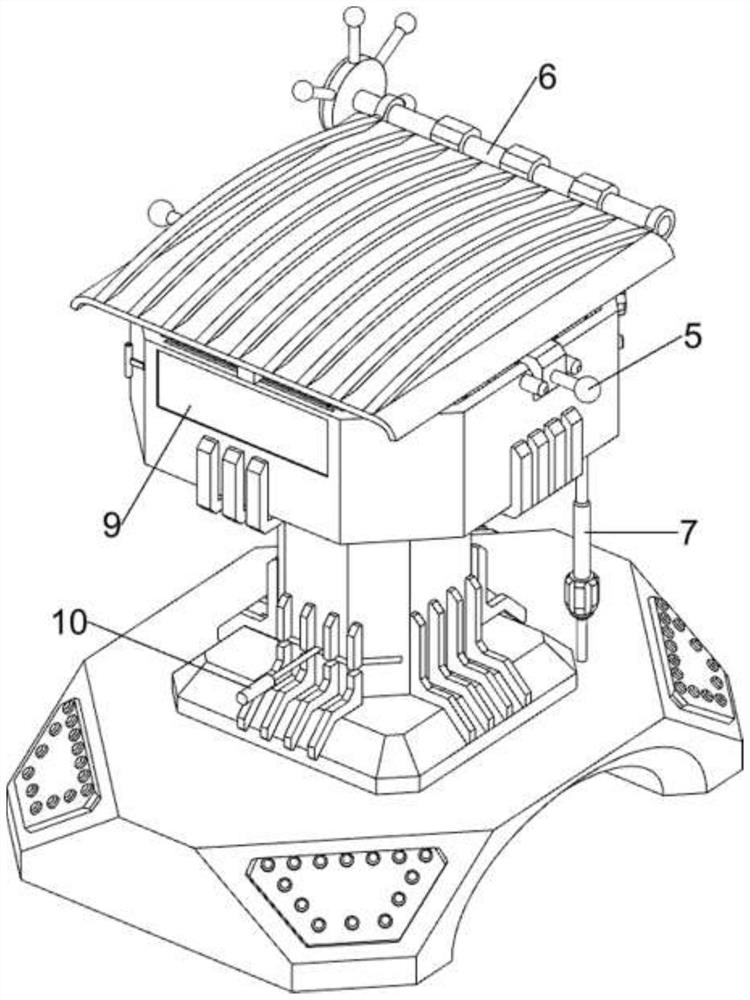

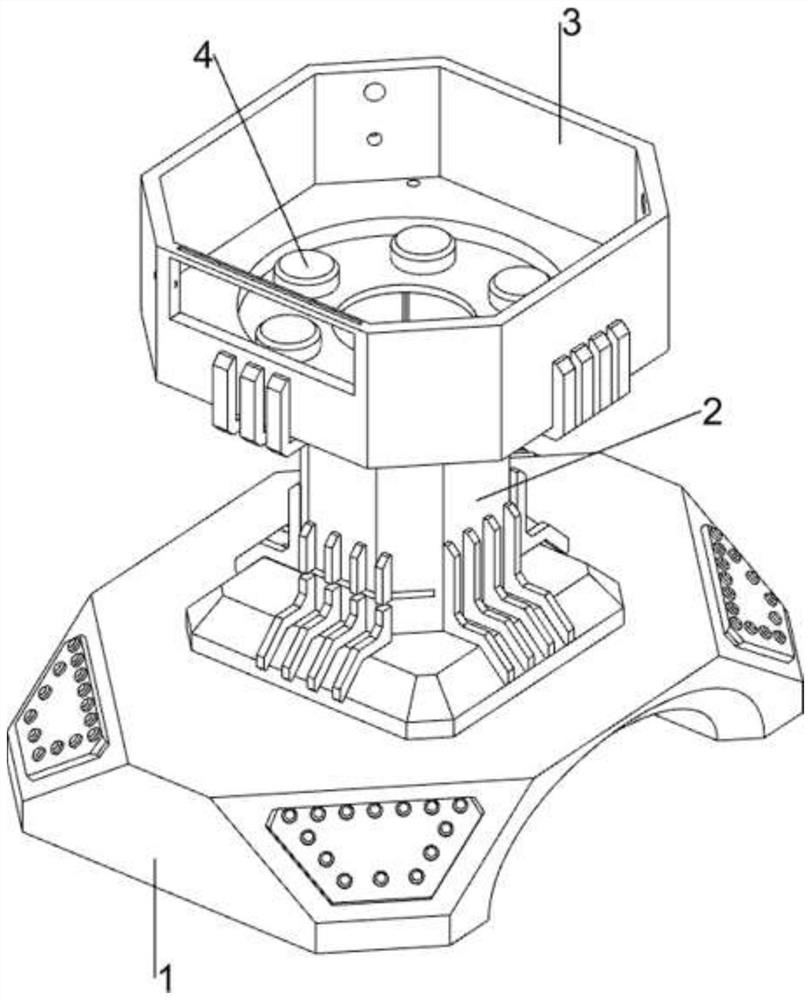

[0029] A vertical ultrasonic cleaning machine for anti-sensitivity oral liquid bottles, such as Figure 1-5 As shown, it includes a base 1, a mounting seat 2, a cleaning box 3, a cleaning device 4, a placement mechanism 5 and an anti-splashing mechanism 6. The mounting seat 2 is provided in the middle of the top of the base 1, and the cleaning box 3 is provided on the top of the mounting seat 2. A cleaner 4 is connected to the cleaning box 3 , a placement mechanism 5 is placed in the cleaning box 3 , and an anti-sputter mechanism 6 is provided on the top of the cleaning box 3 .

[0030] Placement mechanism 5 includes placing box 50, clamping plate 51, clamping rod 52 and handle 53, is placed with placing box 50 in cleaning box 3, and placing box 50 left and right sides is all provided with clamping plate 51, and clamping plate 51 outsides are all provided with. There is a handle 53, and two clamping rods 52 are arranged on the left and right sides of the cleaning box 3.

[00...

Embodiment 2

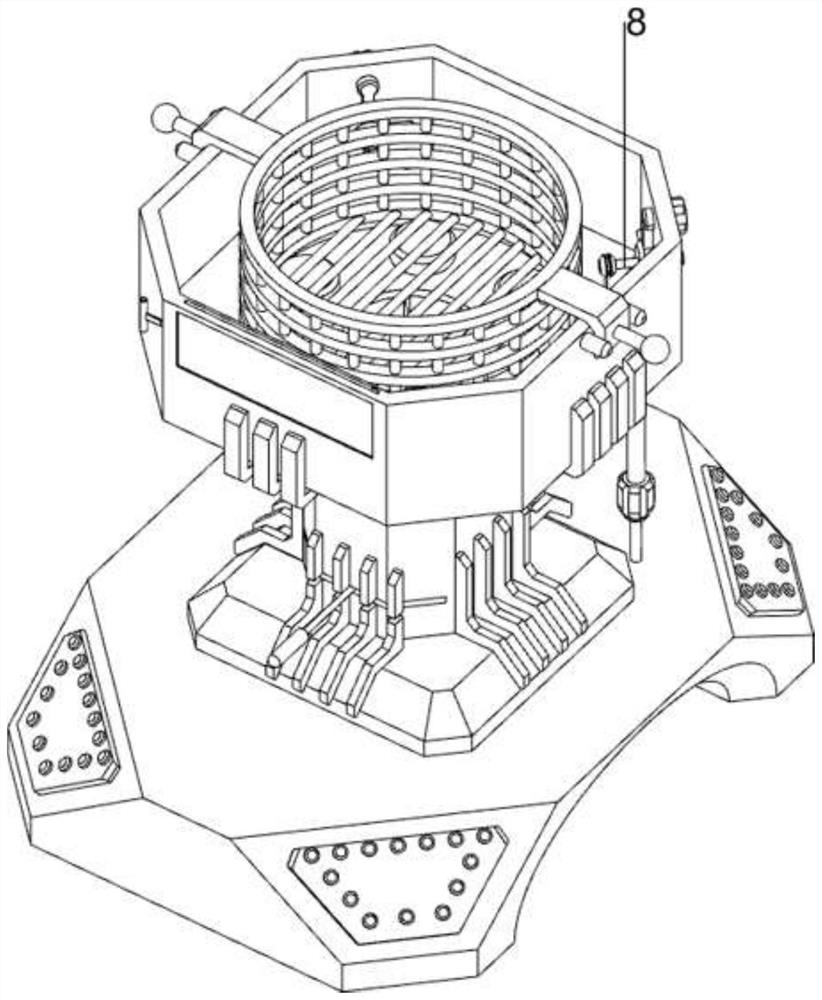

[0034] On the basis of Example 1, such as Figure 6-11 As shown, a liquid inlet mechanism 7 is also included, and the liquid inlet mechanism 7 includes a connecting seat 70, a cylinder 71, a lifting rod 72, a second rotating disk 73, a plug 74, a screw cap 75 and a scroll spring 76, and the rear of the base 1 Side top left and right sides are all provided with connection seat 70, are all provided with cylinder 71 on connection seat 70, are all provided with elevating rod 72 on the telescoping rod on the top of cylinder 71, all left and right sides of cleaning box 3 rear parts are all threadedly connected with screw cap 75, the middle left and right sides of cleaning box 3 rear parts are connected with the second rotating disc 73 in a rotating manner, and the top of the second rotating disc 73 is provided with a plug 74, and the plugs 74 and the openings on the left and right sides of the cleaning box 3 rear The holes fit together, and a scroll spring 76 is arranged between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com