A modular magnetic liquid sealing device

A magnetic liquid and sealing device technology, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems that magnetic liquid sealing devices are not widely used and difficult to assemble, so as to shorten downtime, ensure sealing performance, reduce The effect of friction and wear and temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

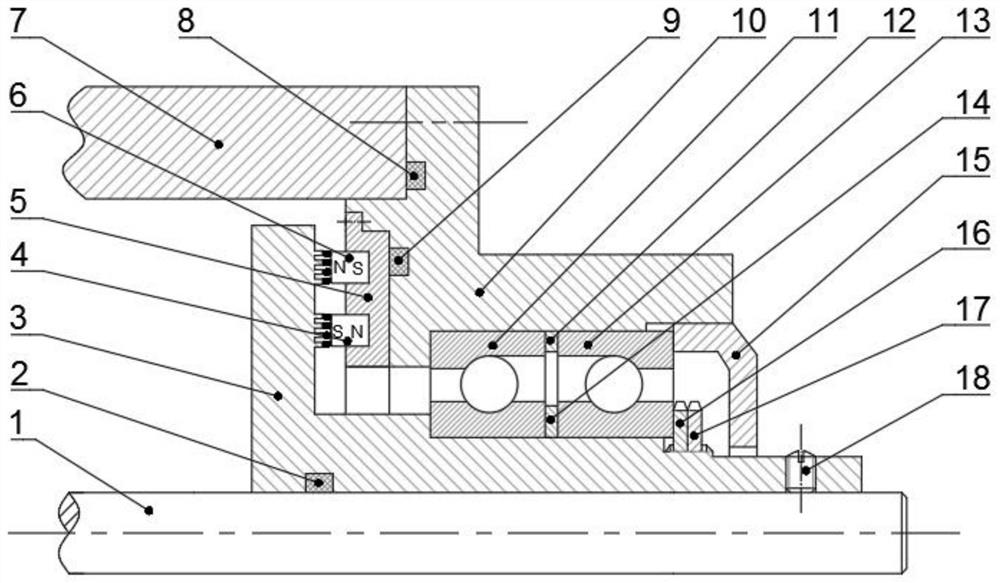

[0013] The present invention is further described by taking the accompanying drawings as a specific embodiment. For the convenience of description, if the words "left" and "right" appear in the following, it only means that they are consistent with the left and right directions of the accompanying drawings, and do not limit the structure.

[0014] A modular magnetic liquid seal such as figure 1 As shown, the device includes: shaft (1), sealing ring I (2), sleeve (3), annular permanent magnet I (4), magnetic conduction ring (5), annular permanent magnet II (6), box (7), seal ring II (8), seal ring III (9), inner shoulder sleeve cup (10), left bearing (11), metal gasket I (12), right bearing (13), metal gasket Ⅱ(14), end cover(15), round nut Ⅰ(16), round nut Ⅱ(17), flat head set screw(18).

[0015] It constitutes the connection between the various parts of the device: the sealing ring I (2) is installed in the groove of the inner surface of the sleeve (3); the sealing ring II (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com