Workshop layout scheduling optimization method based on multi-objective non-dominated sorting

A non-dominated sorting and multi-objective technology, applied in the field of workshop layout scheduling optimization, can solve the problems of lack of theoretical data support, integrated optimization, etc., and achieve the effect of reducing cumbersomeness and improving global search capabilities

Active Publication Date: 2021-07-13

ZHEJIANG UNIV OF TECH

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing workshop scheduling and layout schemes are mostly based on orders and experience, lacking the support of certain theoretical data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

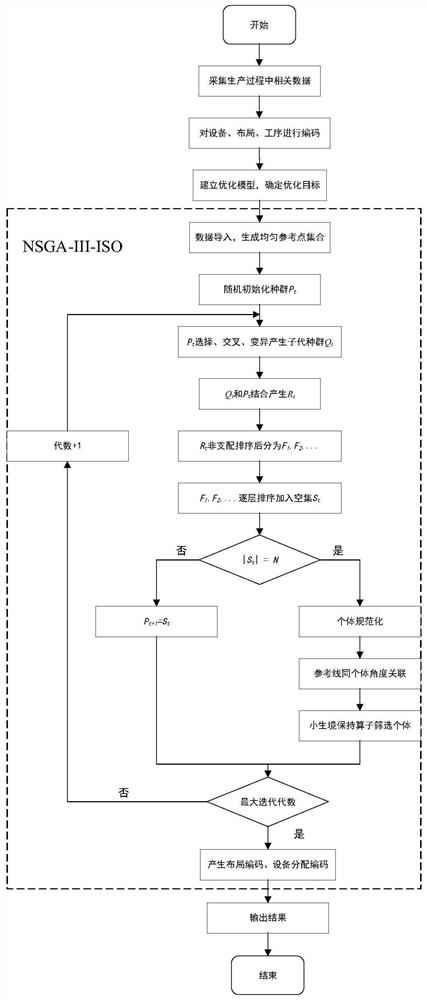

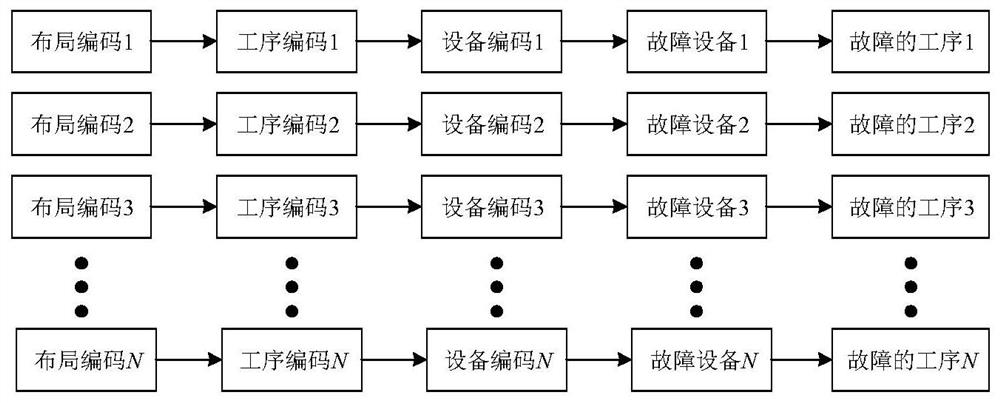

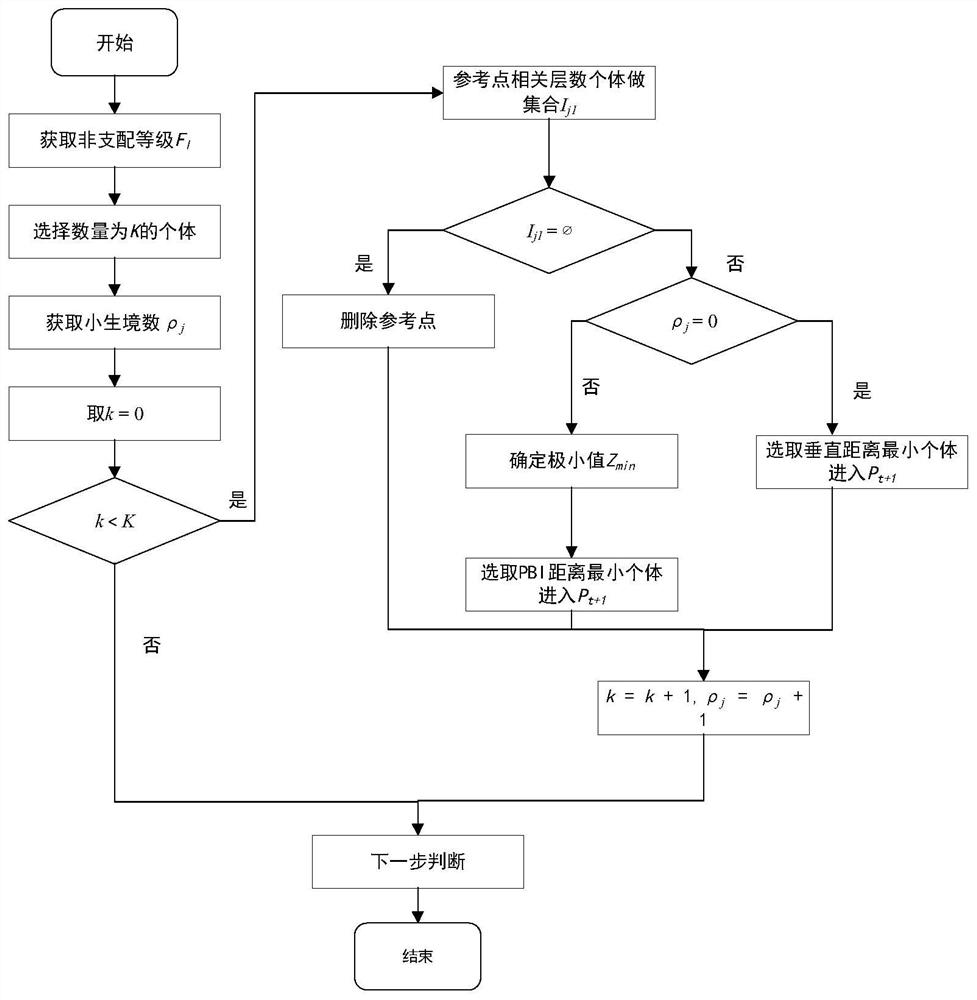

The invention discloses a workshop layout scheduling optimization method based on multi-objective non-dominated sorting. The method comprises the following steps: 1, collecting data related to production resources in an enterprise production process; 2, encoding equipment, layout and processes of a production workshop, and establishing an optimization model; 3, generating a uniform reference point set, and randomly initializing a population Pt of which the scale is N; 4, performing selection, crossover and variation on the population Pt to obtain a filial generation population Qt with the scale of N, and merging the parent population and the filial generation population to obtain a population Rt with the scale of 2N; 5, after the Rt is subjected to non-dominated sorting, dividing the Rt into a plurality of layers such as F1, F2 and the like; 6, indicating that St = F1 union, F2 union... Fl, and until '2jeemaa2' St '2jeemaa2' is greater than or equal to N; 7, normalizing individuals: normalizing all individual targets in the St; 8, setting a clustering operator, and defining the niche number of the ith reference point as rho i; 9, selecting K individuals from the F1 by using the niche number and putting the K individuals into Pt + 1; 10, judging whether the maximum number of iterations is met or not; and 11, generating layout codes and equipment allocation codes.

Description

technical field [0001] The invention relates to a workshop layout scheduling optimization method. Background technique [0002] In actual engineering optimization problems, most of them are multi-objective optimization problems, that is, to optimize the maximum and minimum values of multiple objectives in a specific field such as transportation, factory production, and logistics scheduling. Compared with single-objective optimization problems, multi-objective optimization is often more complicated and difficult to solve, and the optimization goals are usually in conflict with each other. At the same time, it is difficult to find a perfect solution. In most cases, some trade-offs, decision-making, and cooperation are required. High-efficiency algorithms, etc. to obtain better results, and better results generally have a certain degree of robustness. [0003] Evolutionary methods are mostly inspired by biological survival or evolution in nature. Different from traditional ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06Q10/06G06Q50/04G06K9/62

CPCG06Q10/0631G06Q50/04G06F18/23Y02P90/30

Inventor 王亚良范欣宇丁杨科高康洪黄利

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com