Dry anaerobic fermentation equipment for organic waste

A dry anaerobic fermentation, organic waste technology, applied in the direction of solid waste removal, etc., can solve the problem of high stickiness of banana peels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] For example figure 1 -example Figure 5 Shown:

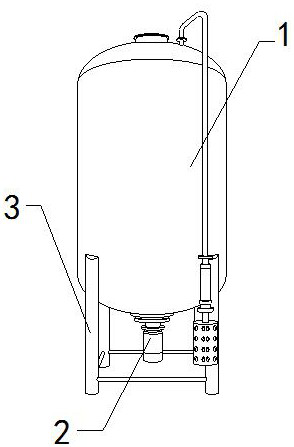

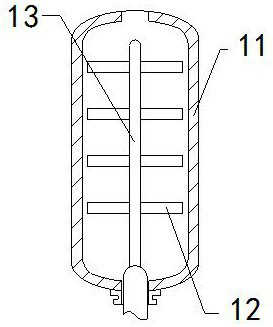

[0029] The present invention provides a dry anaerobic fermentation equipment for organic waste, the structure of which includes a fermenter 1, a driver 2, and a support frame 3, the driver 2 is installed at the bottom of the fermenter 1, and the outer surface of the fermenter 1 Welded with the inner side of the support frame 3; the fermenter 1 includes a shell 11, blades 12, and a rotating shaft 13, the blades 12 are welded to the outer surface of the rotating shaft 13, and the rotating shaft 13 penetrates the inner position of the shell 11.

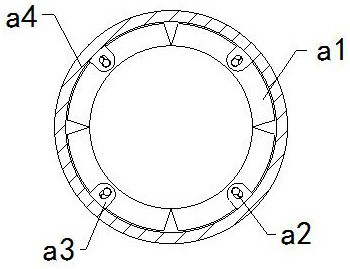

[0030] Wherein, the housing 11 includes an extension plate a1, a rebound piece a2, a transition piece a3, and an outer frame a4. Between the inner side of the block a3 and the protruding plate a1, the inner side of the transition block a3 is attached to the inner wall of the outer frame a4, and there are four protruding plates a1, which are uniformly rounded on the inner side of t...

Embodiment 2

[0036] For example Figure 6 -example Figure 9 Shown:

[0037]Wherein, the contact reducing groove b2 includes a linkage frame b21, a frame body b22, a pull-back bar b23, a lower extension plate b24, and a middle connecting rod b25, and the inside of the linkage frame b21 is slidingly matched with the side of the middle connecting rod b25, The pull-back bar b23 is installed between the inner side of the frame body b22 and the upper end of the lower extension plate b24, the upper surface of the lower extension plate b24 is attached to the bottom of the linkage frame b21, and the middle connecting rod b25 is fixed on The internal upper end position of the frame body b22, through the inertial force generated by the outward extension of the mechanism, can make the lower extension plate b24 extend downward along the middle connecting rod b25 under the cooperation of the linkage frame b21, so that the lower extension plate b24 can The crushed banana peel squeezed into the inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com