Synchronous reversing valve for oxygen-enriched heating furnace

A heating furnace and reversing valve technology, applied to valve details, multi-way valves, valve devices, etc., can solve problems such as poor synchronization of four-way valve switching actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

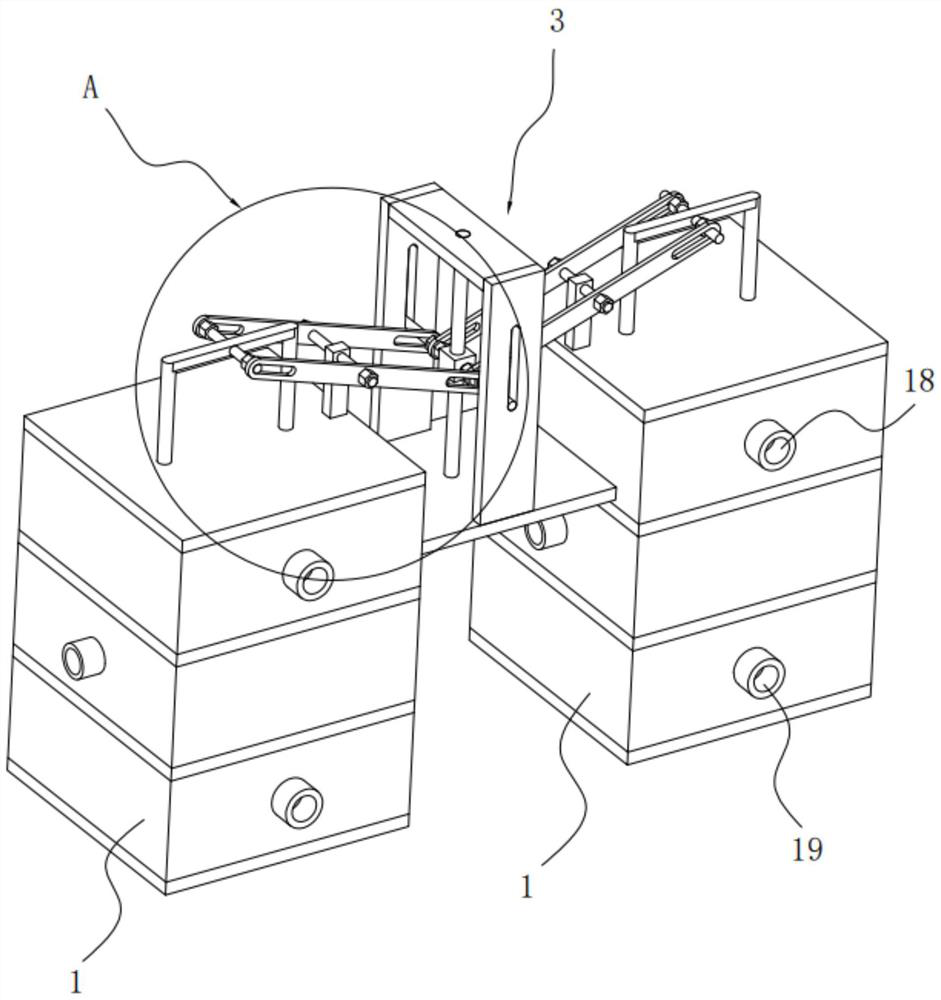

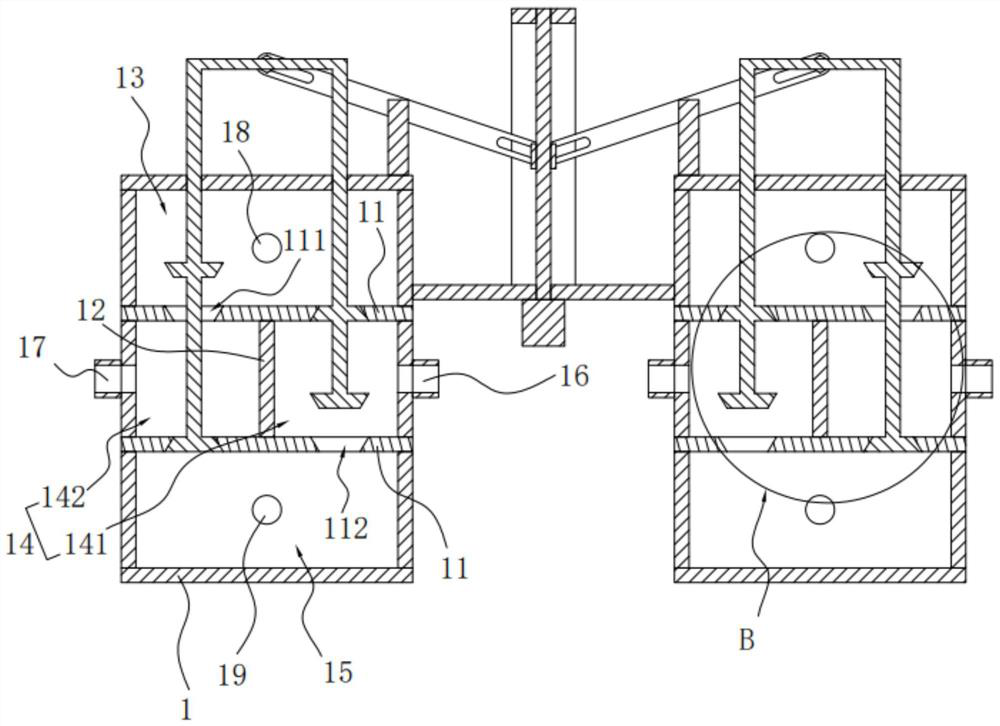

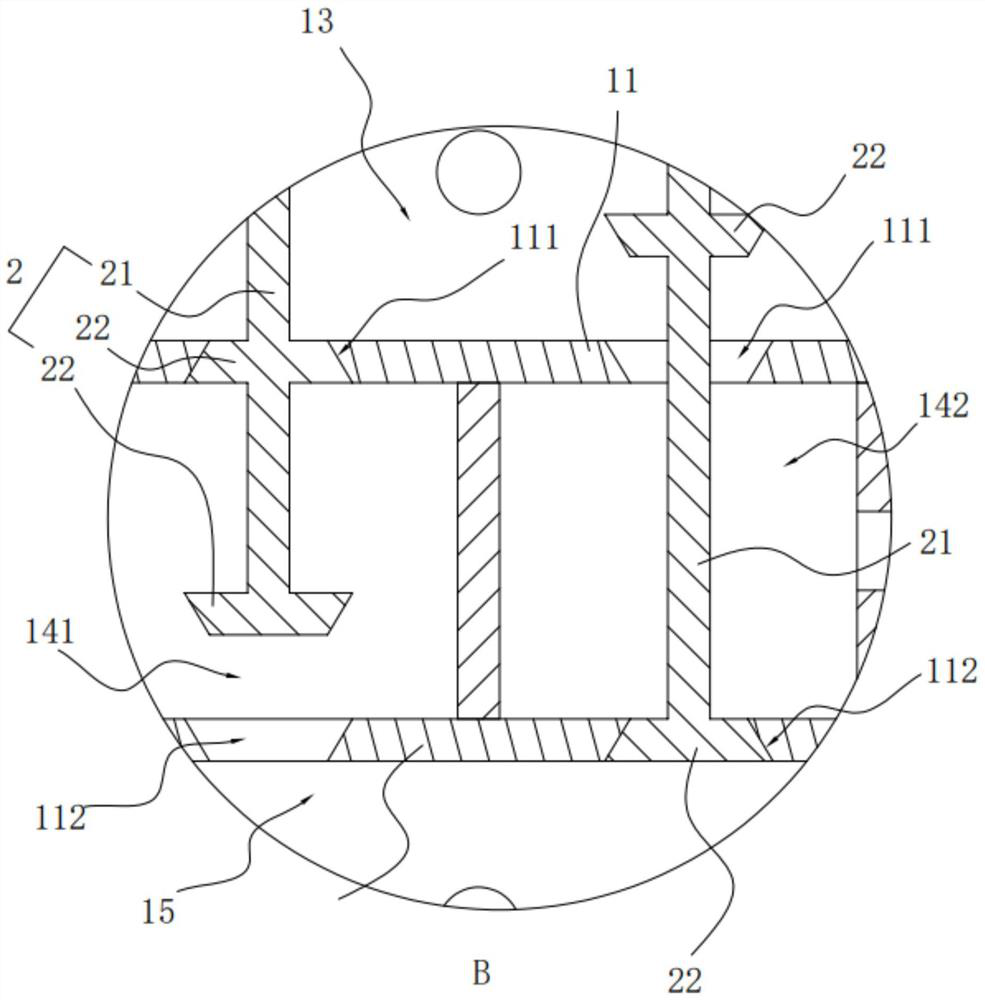

[0045] Embodiment 1: A synchronous reversing valve for an oxygen-enriched heating furnace, see the attached figure 1 , attached figure 2 And attached image 3 , including two valve bodies 1, a valve core 2 arranged in the two valve bodies 1, and a power mechanism 3 for driving the valve core 2 to move; specifically, the two valve bodies 1 have the same structure, and the inside of the valve body 1 is provided with a hollow Cavity, the valve body 1 is provided with two partition plates 11 fixedly connected to the inner wall of the valve body 1, and the two partition plates 11 are arranged in the vertical direction, thereby dividing the cavity in the valve body 1 from top to bottom. It is a fluid chamber 13, a switching chamber 14 and an exhaust gas chamber 15; in the middle of the switching chamber 14, a switching plate 12 is arranged between the two partition plates 11, and the switching plate 12 is fixedly connected with the partition plate 11 and the inner wall of the swit...

Embodiment 2

[0065] Embodiment two: a kind of oxygen-enriched heating furnace, see attached Figure 6 , which includes a furnace body 4, a gas pipe 6 for providing gas for the furnace body 4, an oxygen-enriched air pipe 5 for providing oxygen-enriched air for the furnace body 4, and two exhaust pipes for exhausting the exhaust gas in the furnace body 4. Air pipe 7, four regenerators 41 fixedly connected on the furnace body 4 and the reversing valve in the first embodiment; specifically; the gas pipe 6 and the oxygen-enriched air pipe 5 are connected with the two fluidic inlet pipes of the two valve bodies 1 respectively. 18 connection, the two tail gas pipes 7 are connected with the two tail gas discharge pipes 19 of the two valve bodies 1 respectively, and the four regenerators 41 are connected with the two first connecting pipes 16 and the two second connecting pipes of the two valve bodies 1 respectively.

[0066] Specifically, the two regenerators 41 connected with the two first connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com