Photosensitive chip assembly, mobile terminal, camera module and preparation method thereof

A photosensitive chip and camera module technology, applied in the field of photography, can solve the problems of blurring around and poor photographing quality, and achieve the effect of reducing field curvature and poor photographing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The specific implementation manners of the present invention will be described in more detail below with reference to the drawings and embodiments, so as to better understand the solutions of the present invention and the advantages of various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

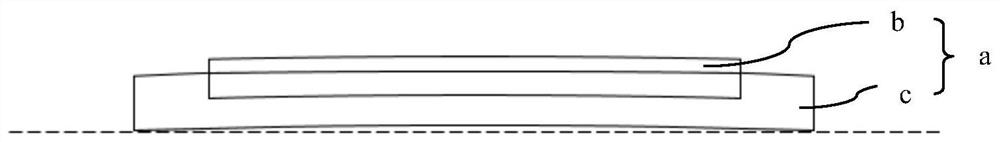

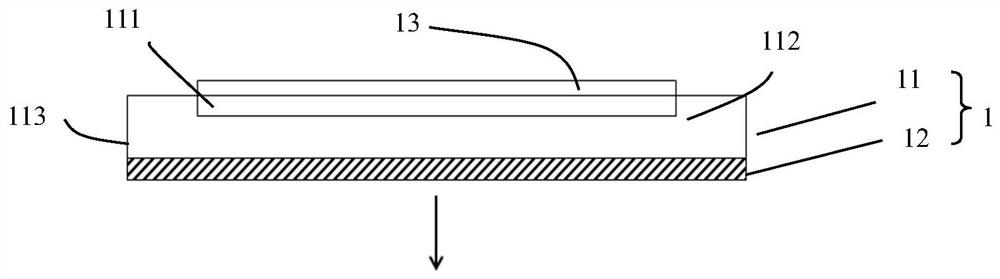

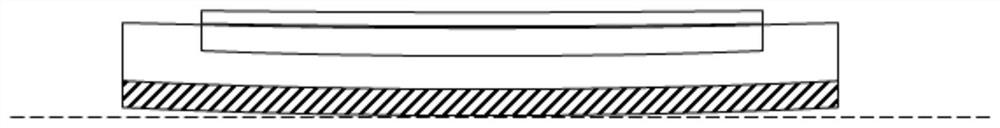

[0096] figure 1 It is a schematic diagram of the deformation state of a traditional photosensitive chip. figure 2 It is a schematic structural diagram of a photosensitive chip assembly according to an embodiment of the present application. Figure 3a It is a schematic diagram of a deformed photosensitive chip according to an embodiment of the present application. Figure 3b It is a schematic diagram of the protruding distance of the part in the photosensitive chip to the direction of the stress film in an embodiment of the present application. Figure 4a It is a schemat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com