Screw fastener for preventing looseness

A screw and tightening technology, applied in the direction of threaded fasteners, screws, nuts, etc., can solve the problems of inconvenient production, inconvenient practical application, complicated operation, etc., to prevent loosening, easy to install or remove, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

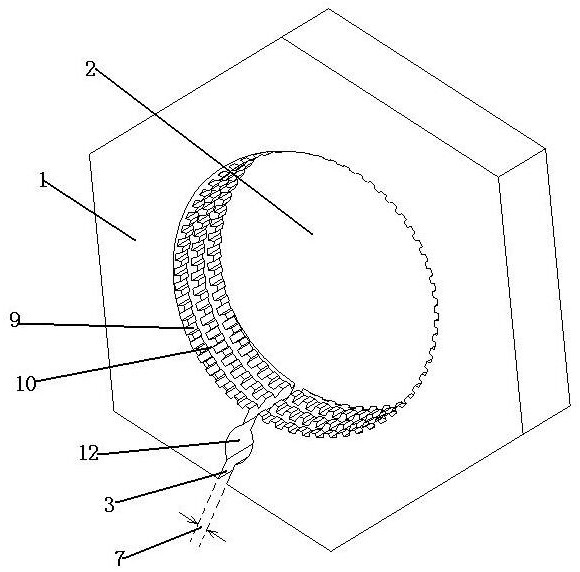

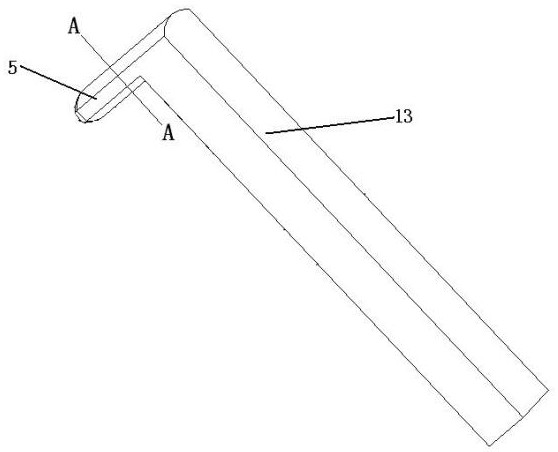

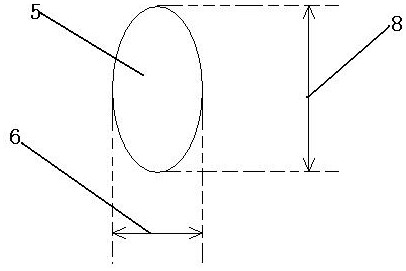

[0035] Such as figure 1 , 2 As shown in , 3, a kind of screw rod holding buckle for preventing slack is made, including a holding button 1, and the holding button 1 is a cylinder with a cylindrical hole 2 in the middle, and the cylindrical hole in the cylinder The side wall of 2 is provided with elastic seam 3, promptly dug a breach on the side of cylinder hole 2 on the cylinder, makes the cylinder hole 2 on the cylinder be the shape of a circle. The inner diameter of the cylindrical hole 2 is slightly smaller than the diameter of the screw rod 4 to be fastened; it is also equipped with a wide and narrow pin 5, and the wide and narrow pin 5 is a bolt, and the narrow diameter 6 of the bolt is less than or equal to the thickness 7 of the elastic seam. The wide diameter 8 of the pin is greater than the thickness 7 of the elastic seam, and the thickness 7 of the elastic seam refers to the distance between the two corresponding surfaces in the elastic seam 3; On both sides, the i...

Embodiment 2

[0041] On the basis of Embodiment 1, a first longitudinal tooth pattern 9 parallel to its central axis is provided on the inner wall of the cylindrical hole 2 of the clasping buckle 1 .

[0042] Alternatively, an internal thread 10 matching the external thread on the screw rod 4 is provided on the inner wall of the cylindrical hole 2 of the clasping buckle 1 .

[0043] Or, on the inner wall of the cylindrical hole 2 of the clasping buckle 1, the internal thread 10 and the second longitudinal tooth pattern are arranged at the same time, that is, the first longitudinal tooth pattern 9 is arranged on the crest position of the internal thread 10, and at the same time the The bottom of the external thread on the screw 4 is provided with a second longitudinal tooth 11 parallel to its central axis, and the second longitudinal tooth 11 and the first longitudinal tooth 9 mesh with each other.

[0044] Or the first longitudinal tooth pattern 9 is arranged at the bottom position of the i...

Embodiment 3

[0046] Such as figure 2 , 3 Shown on the basis of Embodiment 1, an oval hole 12 is dug together in the middle of the two corresponding side walls of the elastic seam 3, and the long diameter of the oval hole 12 is the same as that of the elastic seam 3. Parallel, the short diameter is perpendicular to the elastic seam 3; at the same time, the wide and narrow pin 5 is made into an elliptical structure, the wide diameter 8 is the long diameter of the ellipse, and the narrow diameter 6 is the short diameter of the ellipse.

[0047] The wide and narrow pin 5 is also provided with a handle bar 13 , and the handle bar 13 is perpendicular to the length direction of the wide and narrow pin 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com