Container with folding telescopic structure and using method

A telescopic structure and container technology, which is applied in the field of containers, can solve problems such as equipment damage, easy shaking, and inability to fold, and achieve the effects of improving practicability, protecting from damage, and saving occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

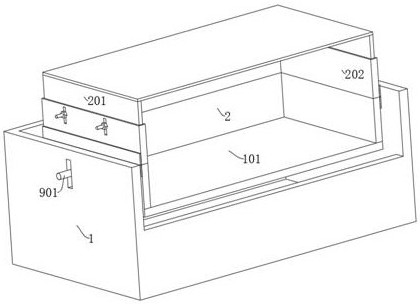

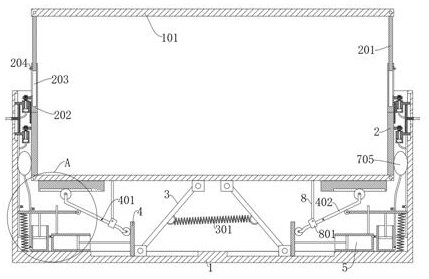

[0041] refer to Figure 1-5 , a container with a folding and telescopic structure, including a frame body 1 and a box body 101, and also includes:

[0042] The first rotating plate 2 is rotatably connected around the bottom of the box body 101;

[0043] The second rotating plate 201 is rotatably connected around the top of the box body 101;

[0044] The connecting plate 202 is slidably connected to the second rotating plate 201 and connected to the first rotating plate 2 through a hinge;

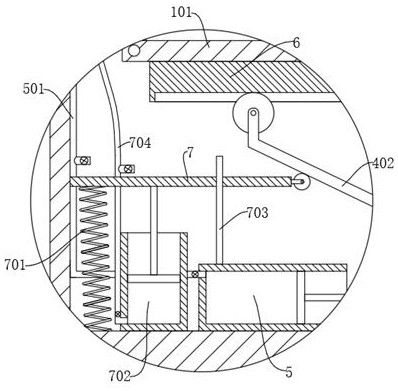

[0045] The bottom of the frame body 1 is provided with a buffer mechanism for supporting the box body 101;

[0046] The side wall of the frame body 1 is provided with a control mechanism to prevent the first rotating plate 2 and the connecting plate 202 from folding automatically;

[0047] The bottom of the frame body 1 is a pneumatic component that can generate gas when the buffer mechanism is working, and the pneumatic component is used to drive the control mechanism to work.

[0048] ...

Embodiment 2

[0057] refer to Figure 1-5 , a container with a folding and telescopic structure, including a frame body 1 and a box body 101, and also includes:

[0058] The first rotating plate 2 is rotatably connected around the bottom of the box body 101;

[0059] The second rotating plate 201 is rotatably connected around the top of the box body 101;

[0060] The connecting plate 202 is slidably connected to the second rotating plate 201 and connected to the first rotating plate 2 through a hinge;

[0061] The bottom of the frame body 1 is provided with a buffer mechanism for supporting the box body 101;

[0062] The side wall of the frame body 1 is provided with a control mechanism to prevent the first rotating plate 2 and the connecting plate 202 from folding automatically;

[0063] The bottom of the frame body 1 is a pneumatic component that can generate gas when the buffer mechanism is working, and the pneumatic component is used to drive the control mechanism to work.

[0064] ...

Embodiment 3

[0073] refer to Figure 1-5 , a container with a folding and telescopic structure, including a frame body 1 and a box body 101, and also includes:

[0074] The first rotating plate 2 is rotatably connected around the bottom of the box body 101;

[0075] The second rotating plate 201 is rotatably connected around the top of the box body 101;

[0076] The connecting plate 202 is slidably connected to the second rotating plate 201 and connected to the first rotating plate 2 through a hinge;

[0077] The bottom of the frame body 1 is provided with a buffer mechanism for supporting the box body 101;

[0078] The side wall of the frame body 1 is provided with a control mechanism to prevent the first rotating plate 2 and the connecting plate 202 from folding automatically;

[0079] The bottom of the frame body 1 is a pneumatic component that can generate gas when the buffer mechanism is working, and the pneumatic component is used to drive the control mechanism to work.

[0080] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com