Gob-side entry retaining method for large-dip-angle coal seam

A technology of large inclination and empty entry retaining, which is applied in earth-moving drilling, surface mining, wellbore lining, etc., can solve the technical hazards of roadside support, instability of rigid support body, complicated construction process, etc. The effect of reducing the installation workload, reducing the masonry height, and saving the cost of roadway retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

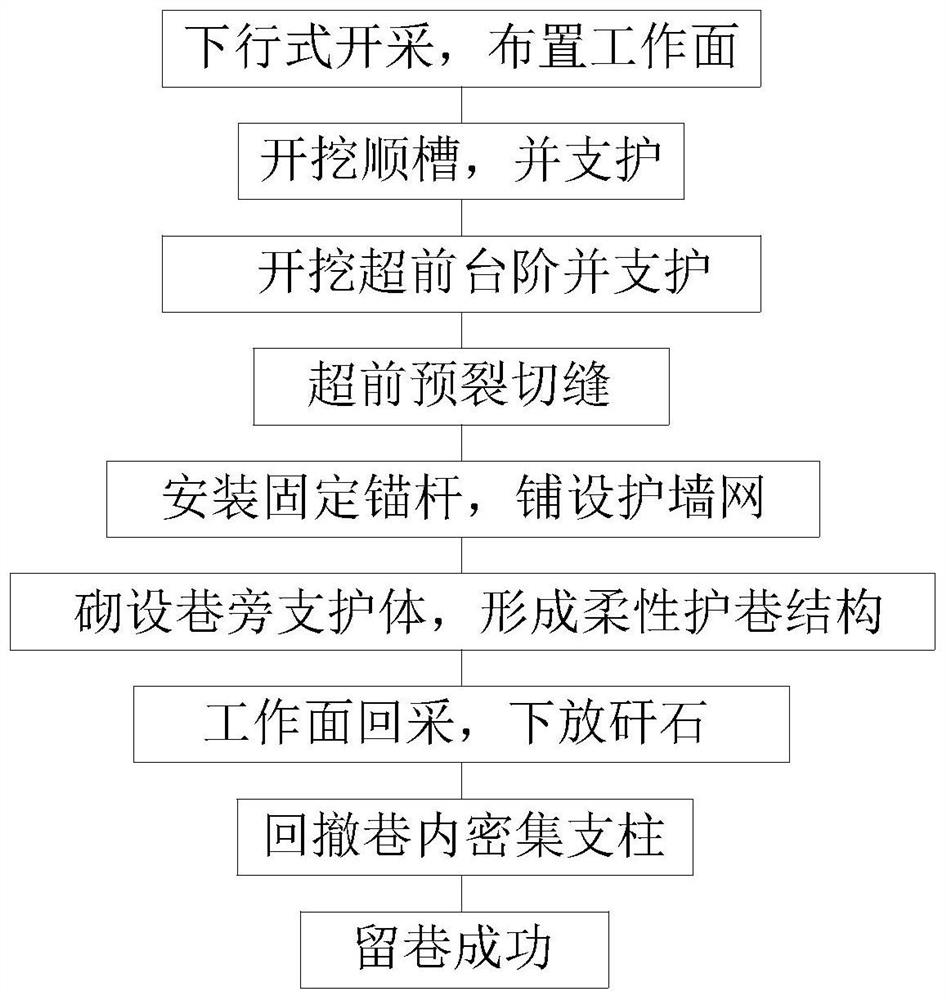

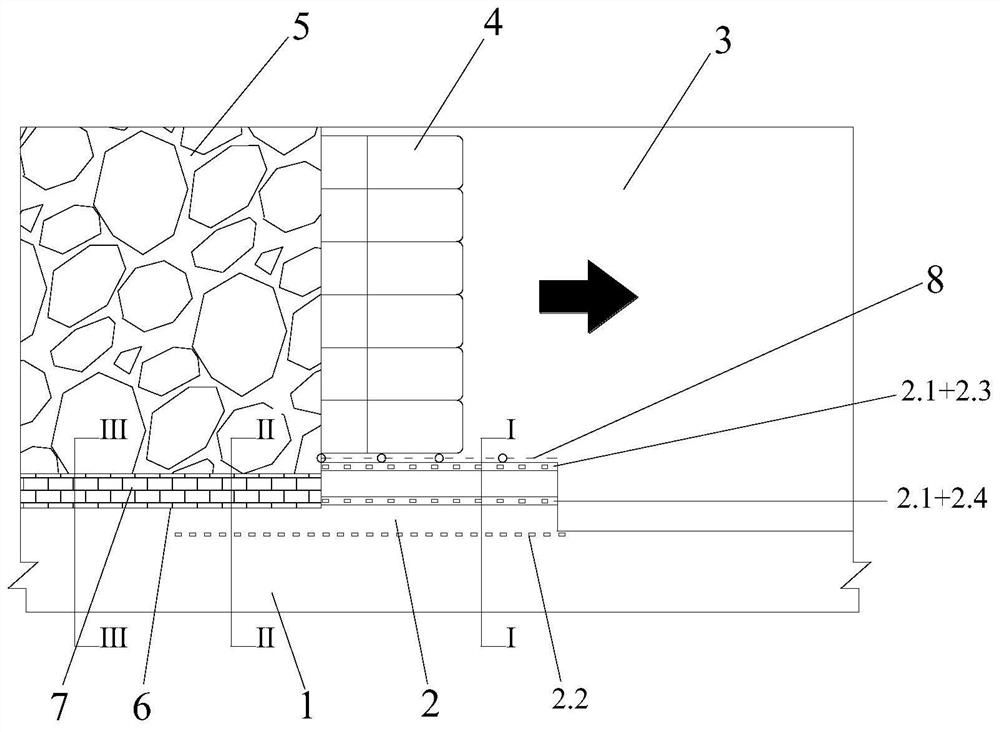

[0027] Such as Figure 1 to Figure 5 Shown, concrete steps of the present invention are:

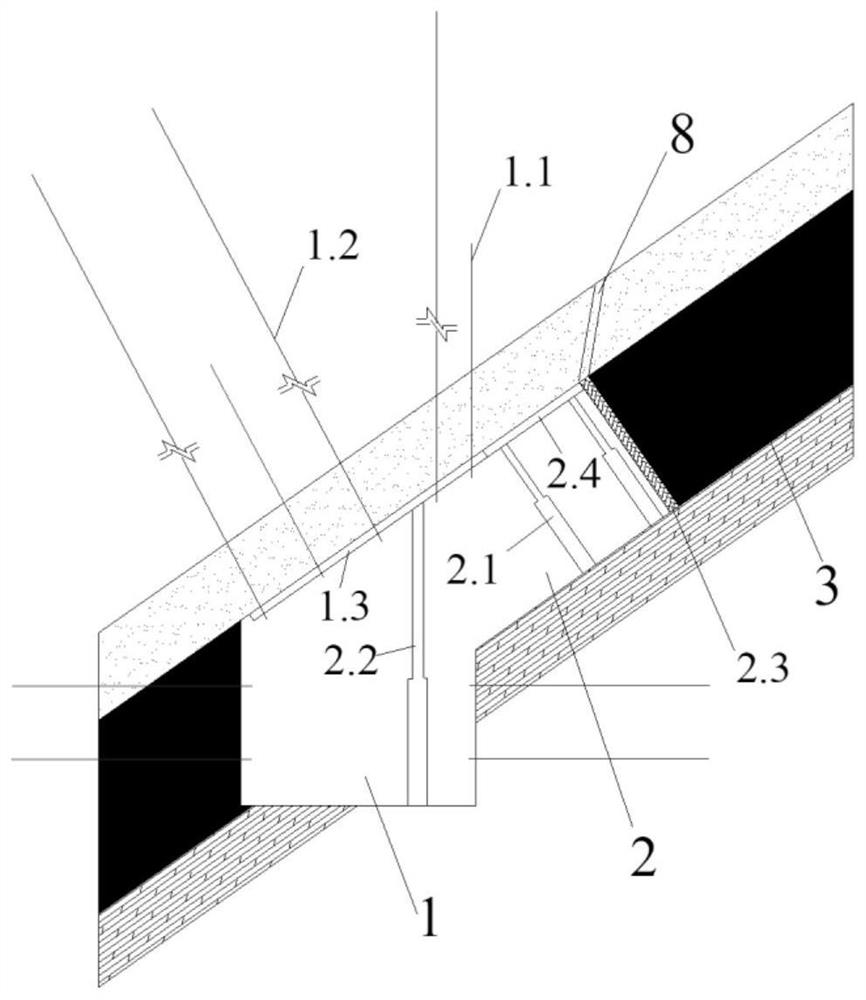

[0028] A. Use the descending mining method to arrange the working face 3; then excavate the tunnel, and use the anchor rod 1.1 or the anchor cable 1.2 plus the steel belt 1.3 for support;

[0029] B. During the recovery process of working face 3, construct a length of 10-20m along the direction of working face 3 from the lower end of working face 3 (the end of working face 3 that is closer to the ground is the upper end and the other end is the lower end) , a super-front step 2 with a width of 2-3m, while using multiple rows of single pillars 2.1 plus hinged top beams 2.4 to support the roof exposed by the super-front steps 2, wherein the hinged top beams 2.4 are supported by the single pillars 2.1 and the top plate Pressing and contacting, the distance between single pillars 2.1 in each row is 0.6-1.0m; the distance betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com