Oxygen and methane torch ignition device and torch generation method thereof

An ignition device and methane technology, which are applied in combustion methods, gas fuel burners, indirect carbon dioxide emission reduction, etc., can solve the problems of low ignition energy and high temperature of the inner wall of the ignition device, so as to relieve heat load, reliable cooling, and improve thermal environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

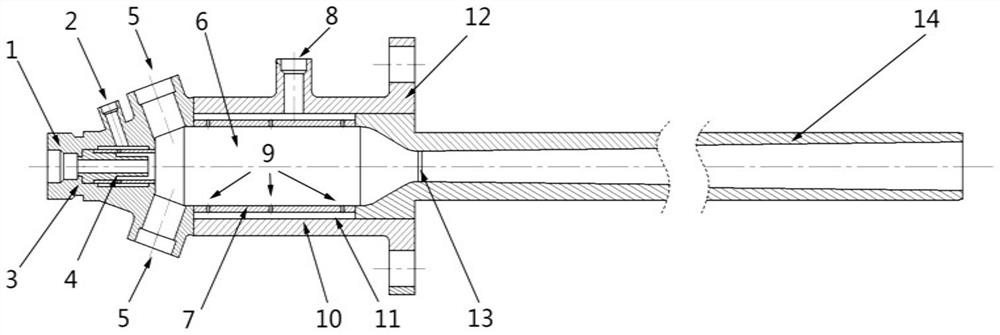

[0036] This embodiment provides a figure 1 The gas-oxygen methane ignition device shown includes a head 3, a body and a gas conduit 14 connected in sequence.

[0037] The gas-oxygen inlet 1 and the coaxial nozzle 4 are sequentially arranged in the head 3 along the gas flow direction, and the gas-oxygen inlet 1 is coaxial with the center of the coaxial nozzle 4, and the side wall of the head 3 is arranged in sequence along the gas flow direction. An igniter 5, the igniter 5 is symmetrically arranged and staggered by 90° radially with the nozzle methane inlet 2; the coaxial nozzle 4 includes an inner nozzle and an outer nozzle coaxially arranged, and the inner nozzle communicates with the gas oxygen inlet 1 , the outer nozzle communicates with the methane inlet 2 of the nozzle; the gas flow direction refers to the gas flow direction of oxygen and methane gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com