Improved foaming behaviour of polymer compositions using passive nucleation

A composition and polymer technology, used in the production of foamed polymer compositions and cables, which can solve problems such as negative environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] 1. Measurement method

[0063] a) Melt flow rate

[0064] The melt flow rate (melt flow rate, MFR) was determined according to ISO 1133-1 and expressed in g / 10 min. MFR is an indicator of the fluidity of a polymer, and thus of its processability. The higher the melt flow rate, the lower the viscosity of the polymer.

[0065] Measure the MFR of polyethylene (co)polymer at a temperature of 190°C and a load of 2.16kg 2 . Measure the MFR of polypropylene (co)polymer at a temperature of 230°C and a load of 2.16 kg 2 .

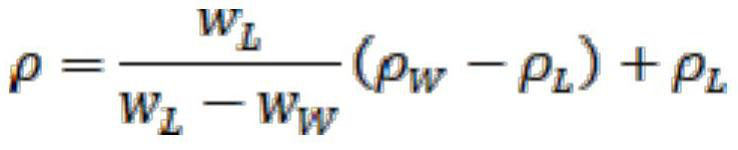

[0066] b) Density of solid material

PUM

| Property | Measurement | Unit |

|---|---|---|

| polymeric | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com