Packaging film for vacuum insulation panel and vacuum insulation panel

A technology of vacuum insulation panels and packaging films, which is applied in the direction of layered products, chemical instruments and methods, glass/slag layered products, etc., which can solve the problems of low thermal conductivity and increased thermal conductivity of aluminum-coated films that affect energy saving effects and product quality. Large and other problems, to achieve the effect of stable and controllable quality, long stretch life, and strong tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A packaging film for a vacuum heat insulation panel, which comprises: a protective layer, a gas barrier layer and a heat-welding layer, and the heat-sealing layer is an ETFE material layer with a thickness of 15-95 μm.

[0052] As the protective layer, a coextruded stretched film (hereinafter referred to as a coextruded stretched film) obtained by sequentially laminating a nylon-based resin, an ethylene-vinyl alcohol copolymer, and a nylon-based resin is used. This co-extruded stretched film does not use an adhesive, but by co-extruding, a flexible nylon-based resin is laminated on both sides of the gas-barrier ethylene-vinyl alcohol copolymer to give it flexibility. and gas barrier properties.

[0053] The thermally welded layer constituting the packaging film for vacuum heat insulating materials of the present invention has the highest air permeability in the packaging film for vacuum heat insulating materials, and the properties of the thermally welded layer have a g...

Embodiment 2

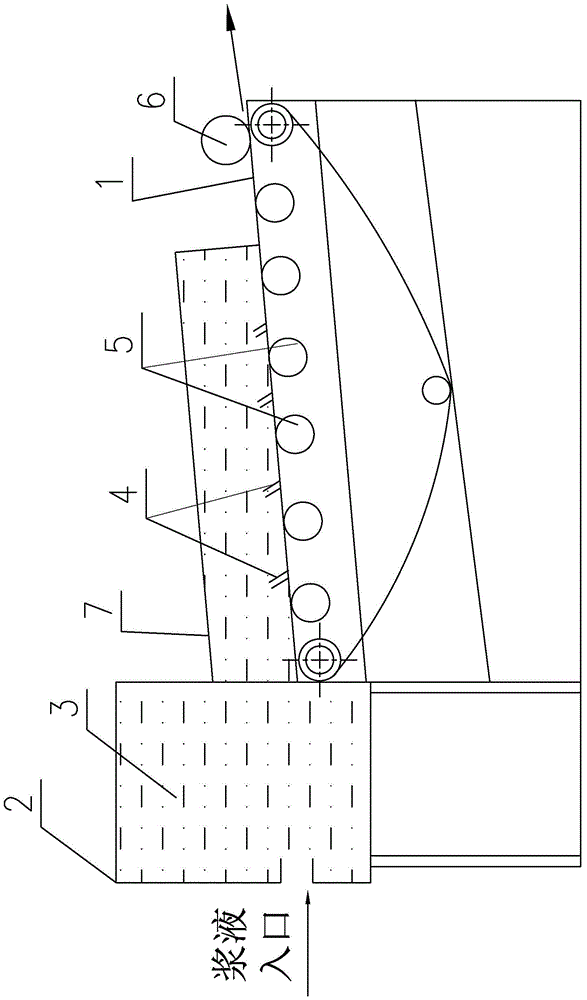

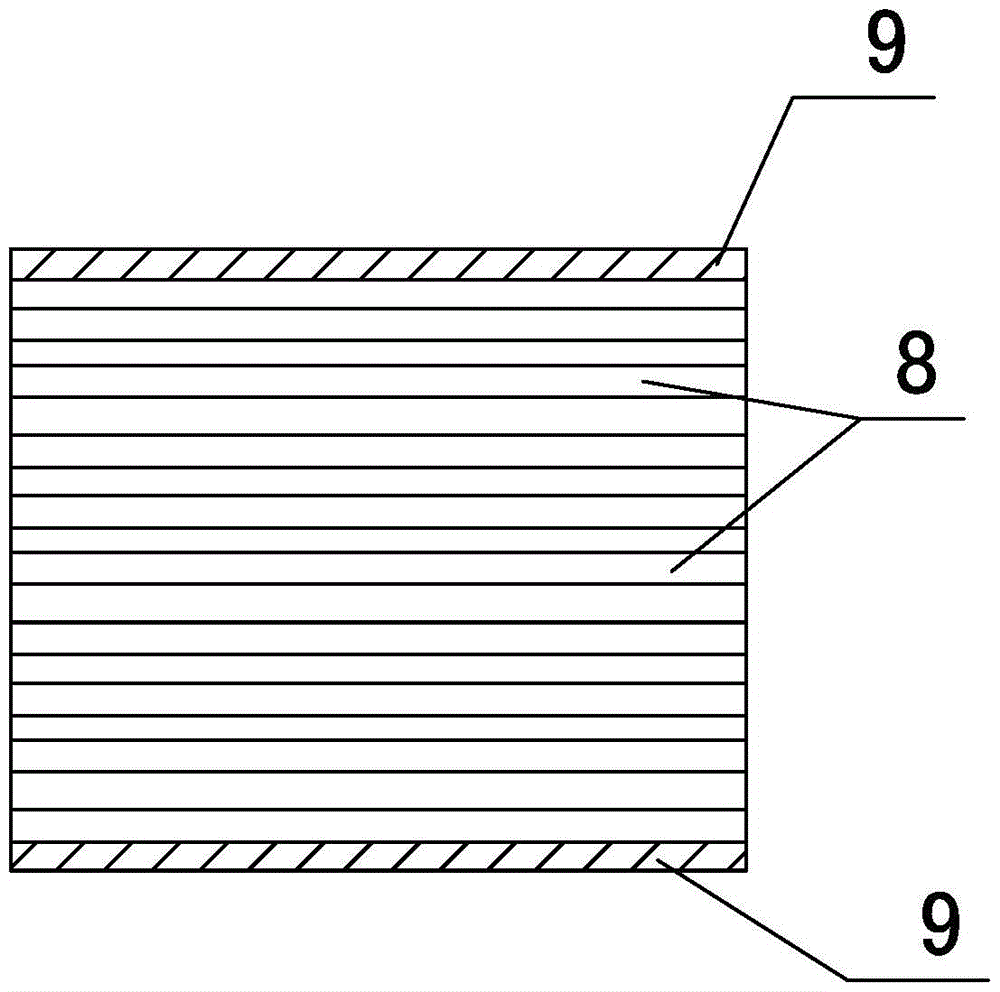

[0062] The vacuum insulation panel made of the film material of the above-mentioned embodiment 1, which includes a core material; as figure 2 , the core material includes an intermediate core material composed of 10 to 30 laminated glass fiber sheets 8 formed by a wet papermaking method (ie, a chopped strand core material); the upper and lower sides of the intermediate core material are completely covered with at least A layer of ultra-fine glass fiber cotton sheet 9; the fiber diameter in the ultra-fine glass fiber cotton sheet 9 is 1-4 μm and the length is 1-5 mm, and the thermal conductivity of the vacuum insulation panel made of the core material is ≤ 0.0025W / m.k.

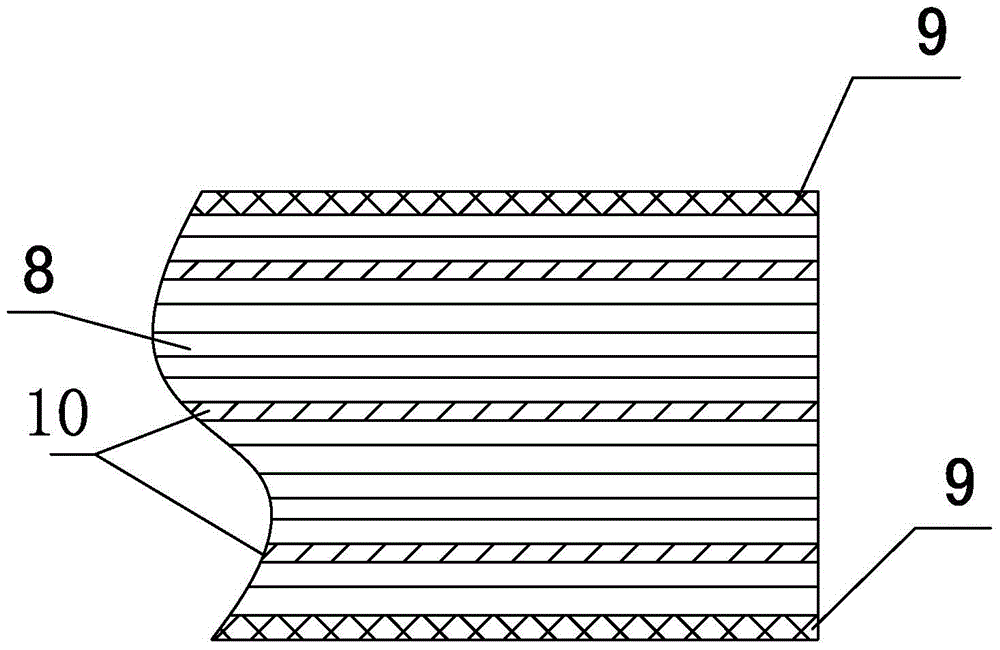

[0063] As a variable embodiment, the intermediate core material is arranged in a bag made of the above-mentioned ultra-fine glass fiber cotton sheet, or the above-mentioned ultra-fine glass fiber cotton sheet 9 wraps the surrounding edges of the intermediate core material To avoid direct contact between the e...

Embodiment 3

[0079] On the basis of Example 2, the vacuum insulation panel core material of this example has the following modifications:

[0080] The intermediate core material is composed of a multi-layer glass fiber sheet formed by wet papermaking after uniform mixing of glass fiber chopped strands and glass fiber cotton, and at least one layer of single-layer glass fiber formed by dry-laid non-woven fabric technology. The mats are alternately stacked and formed, and then the superfine glass fiber cotton sheet is laid on the upper and lower sides of the middle core material. The thermal conductivity of the vacuum insulation panel made of the core material is ≤0.0025W / m.k.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com