Multi-part connector assembly

A technology of connector components and holding components, which is applied in the direction of pipeline connection arrangement, hose connection device, coupling, etc., can solve the problems of large installation space, etc., and achieve the effect of increasing pull-out friction and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

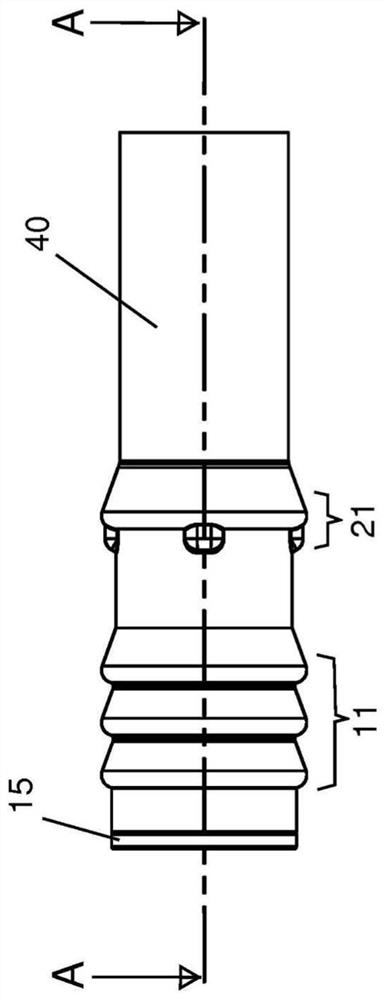

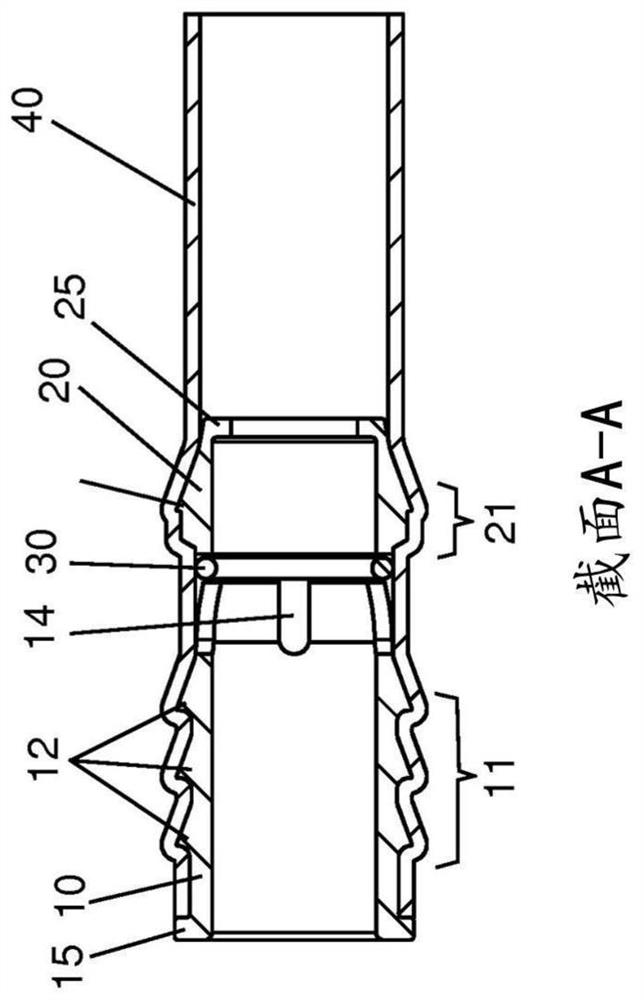

[0020] Figure 1a shows the to-be-connected Figure 2a Hose end 40 of sleeve 50 is shown. The hose end 40 fits snugly onto the outer surfaces of the first and second members 10 , 20 such that its outer profile is similar to that of the first and second members 10 , 20 . Only the flange portion 15 of the first member 10 remains outside the hose 40, and Figure 1a and 1d is shown on the far left. From Figure 1c and Figure 2c These details are best seen and understood in the cross-sectional view of .

[0021] Figure 1c A connector assembly consisting essentially of three parts is shown: a first retaining member 10 to engage the hose 40 and socket 50, a second retaining member 20 to engage the hose 40, and an O-ring 30 form A sealing element is inserted axially between the first and second members 10 , 20 and is adapted to form a seal between the outer surface of the sleeve 50 and the inner surface of the hose 40 .

[0022] The first retaining member 10 has a first flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com