Anti-precipitation hardware paint spraying material cylinder

An anti-sedimentation and material tank technology, applied in the direction of spraying devices, can solve the problems of precipitation and spraying effect reduction, and achieve the effect of avoiding sedimentation and stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

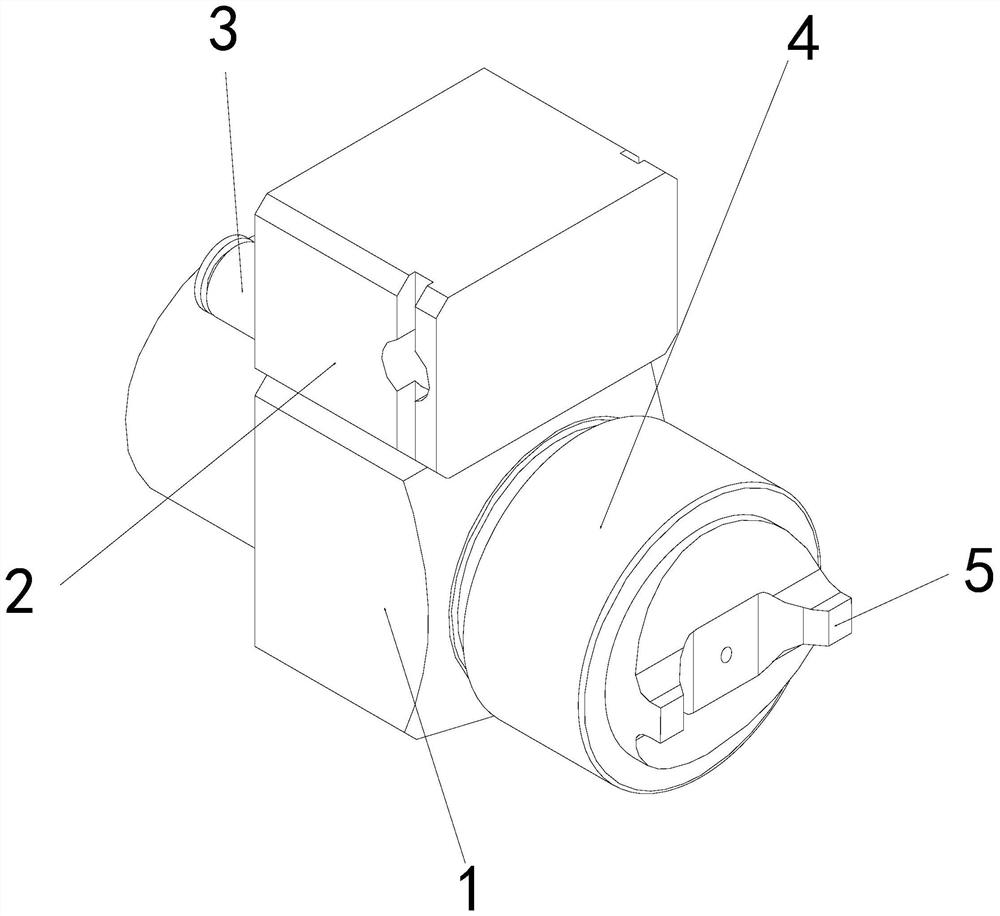

[0029] as attached figure 1 to attach Figure 5 As shown, the present invention provides a kind of anti-sedimentation metal spray paint tank, its structure includes nesting box 1, wiring box 2, connection port 3, material tank 4, docking block 5, and the lower end of the wiring box 2 is screwed It is fixed on the outer wall of the upper end of the nesting box 1, the front end of the connection port 3 is embedded and engaged with the rear end of the cable management box 2, the outer wall of the rear end of the material cylinder 4 is embedded and engaged with the inner wall of the nesting box 1, and the docking block 5. The rear end is welded and fixed on the front surface of the material cylinder 4;

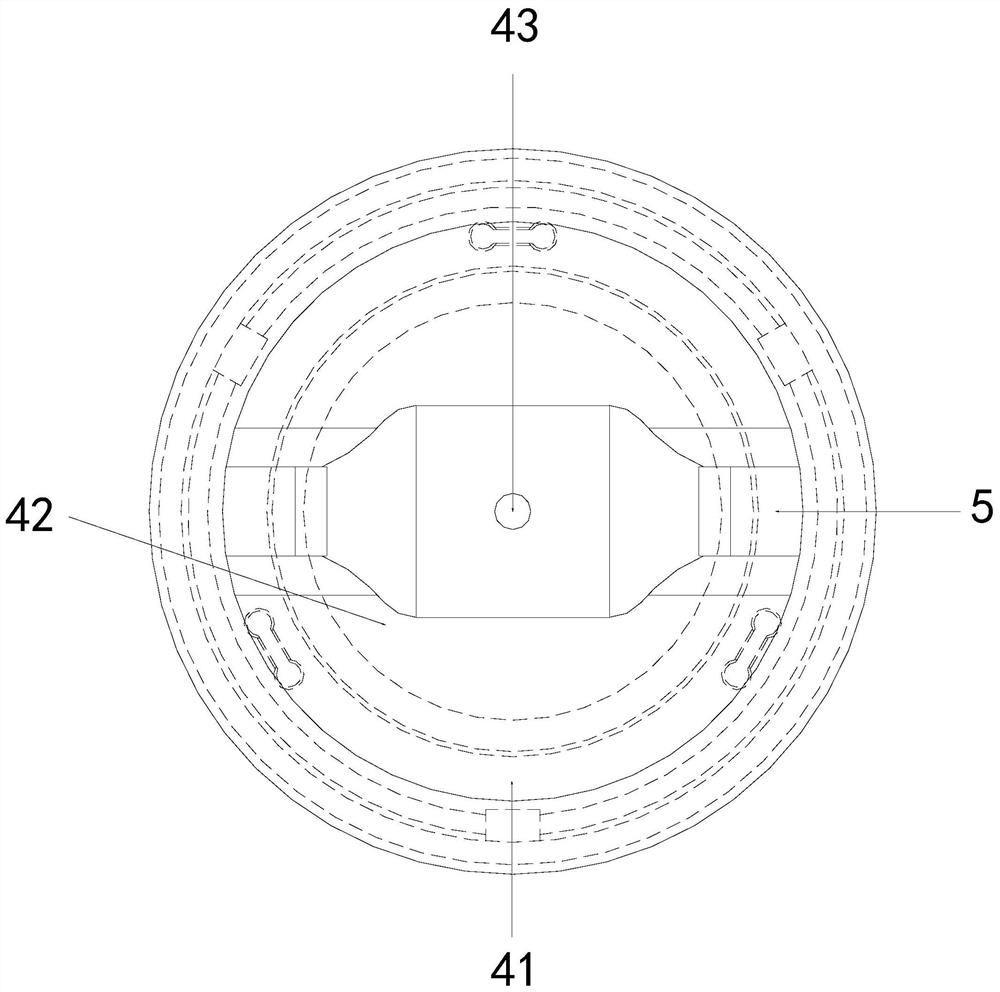

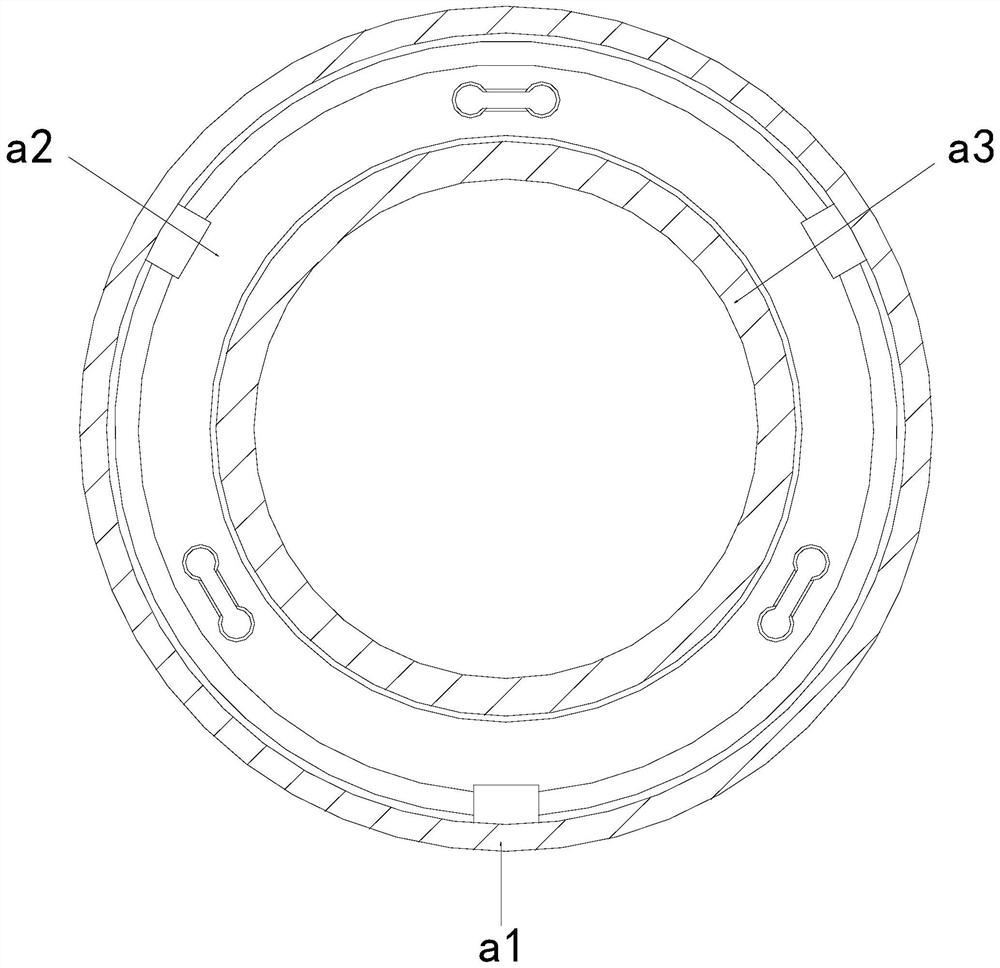

[0030] The material cylinder 4 is composed of a loading cylinder 41, an end plate 42, and a connecting hole 43. The outer wall of the front end of the loading cylinder 41 is embedded and engaged with the outer wall of the rear end of the end plate 42. The connecting hole 43 and t...

Embodiment 2

[0036] as attached Figure 6 to attach Figure 9 As shown: the shock generating mechanism c1 is composed of a ring shock device d1, a fixed frame d2, a closed buckle d3, a fixed hook d4, and a connecting rod d5. The outer walls of both ends of the ring shock device d1 are embedded and engaged with the inner wall of the fixed hook d4 , the inner wall at both ends of the airtight buckle d3 is nested and fixed on the outer wall between the fixed frame d2, the outer wall at both ends of the fixed hook d4 is welded and fixed between the connecting rod d5, and the two ends of the connecting rod d5 are embedded and connected to the airtight buckle The outer wall between d3, the outer wall at the lower end of the fixing frame d2 is embedded and fixed on the inner wall of the housing c2, and there are two fixing frames d2, which are relatively arranged at the two ends of the ring shock device d1, and the fixing frames d2 provided at both ends can be The force of the ring shock device ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap