High-speed impact filing rounding device for balls

A technology of high-speed impact and ball rolling, which is applied in the direction of file/file device, file/file device, other manufacturing equipment/tools, etc., and can solve the problem of low efficiency, low efficiency and slow speed of file disc deburring, etc. problem, to achieve the effect of saving tool consumption, reducing pressure and reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0019] The present invention will be described in further detail below in conjunction with specific embodiments and drawings.

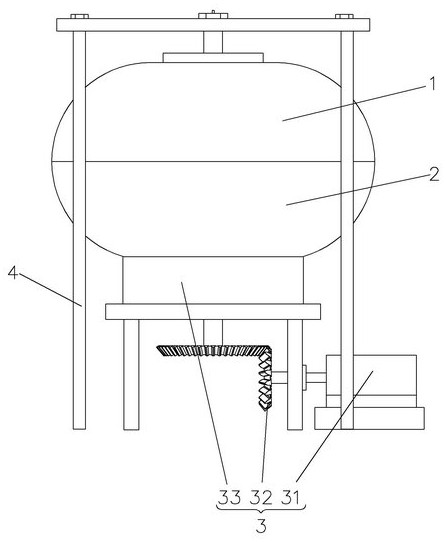

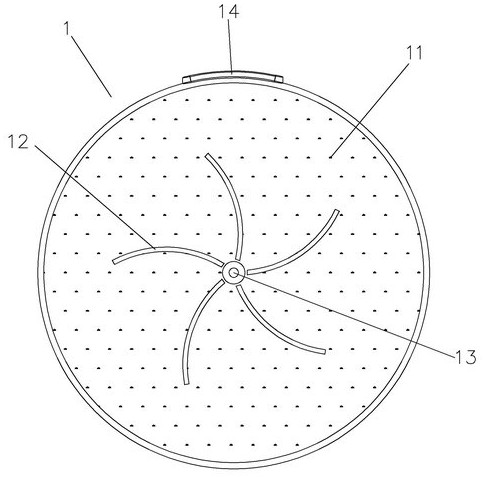

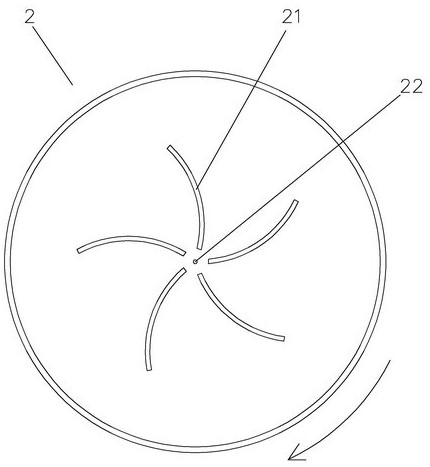

[0020] A preferred embodiment, reference Figure 1 to 4 A high-speed impact of the ball for the ball, including the upper bobbin 1 for boring the ball moving on the surface of the upper bumper 1, and the ball is moving in the inner surface of the bog box 1 Then finally returned to the downlift box 2; the downlift box 2, which will enter the ball in the downlift box 2 by rotation, and the entry into the inner surface of the split on the insertion box 1 The drive mechanism 3 is used to drive the downlift case 2 to rotate. In the present embodiment, it can be further improved, and the frame 4 is provided, and the upper bile box 1 and the drive mechanism 3 are provided on the rack 4, and the downlift case 2 is disposed on the drive mechanism 3. Specifically, the rack 4 can be further split into the upper bobbin bracket and the downlift case bracket, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com