Composite plastic woven bag manufacturing and processing equipment and method

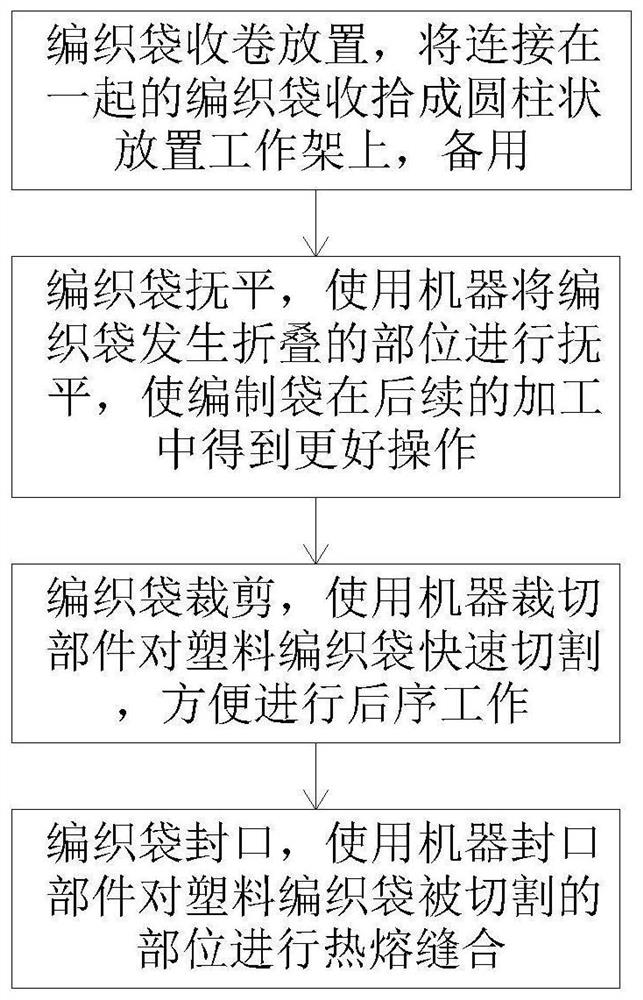

A kind of processing equipment and composite plastic technology, which is applied in bag making operations, flexible container manufacturing, paper/cardboard containers, etc. It can solve the problems of woven bag folding, inconvenience, and inability to cut plastic woven bags, so as to achieve good operation and improve Use effect, effect of convenient post-sequence work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

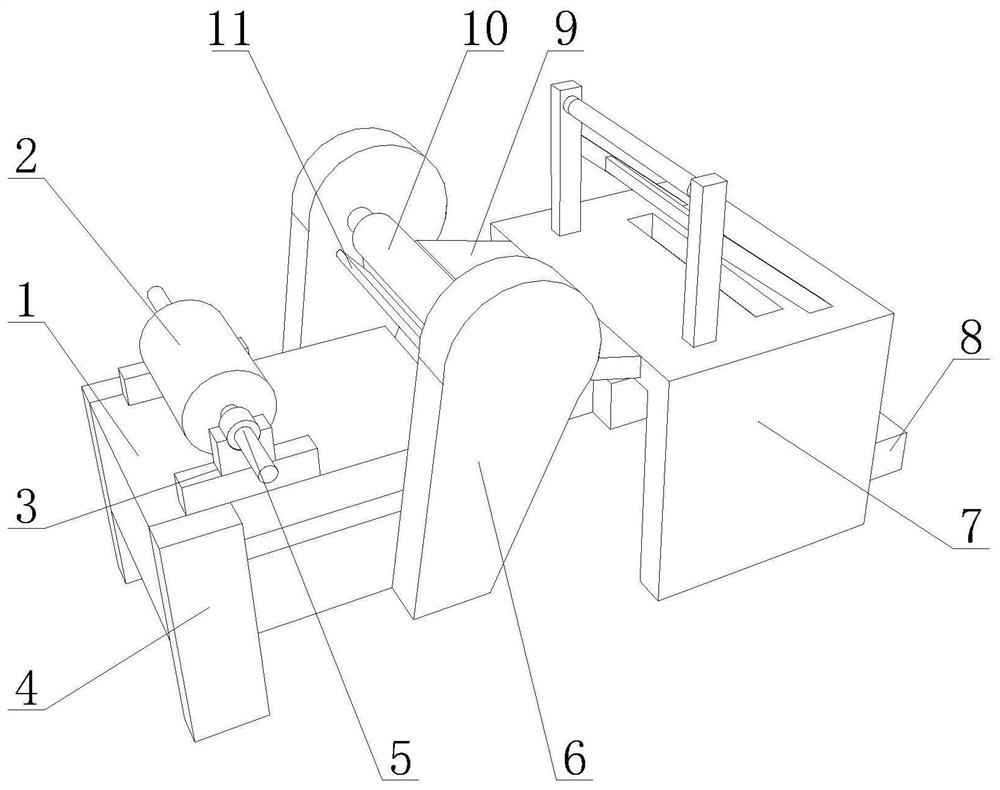

[0034] Such as Figure 1-Figure 5As shown, the present invention provides a composite plastic woven bag production and processing equipment and method, including the production of processing equipment main body 1, woven bag roller 2, support fixed table 3, main body support column 4 and rotating mechanism 5, and the production of processing equipment main body The top left and right sides of the top of 1 are fixedly equipped with a support and fixed platform 3, and the top of the support and fixed platform 3 is movably equipped with a rotating mechanism 5, and the inner side of the rotating mechanism 5 is movably installed with a woven bag roller 2, and the left and right sides of the main body 1 of the production and processing equipment are fixed. The main body support column 4 is installed, and the outside of the production and processing equipment main body 1 is fixedly installed on one side of the main body support column 4. The fan-shaped fixing plate 6 is fixedly install...

Embodiment 2

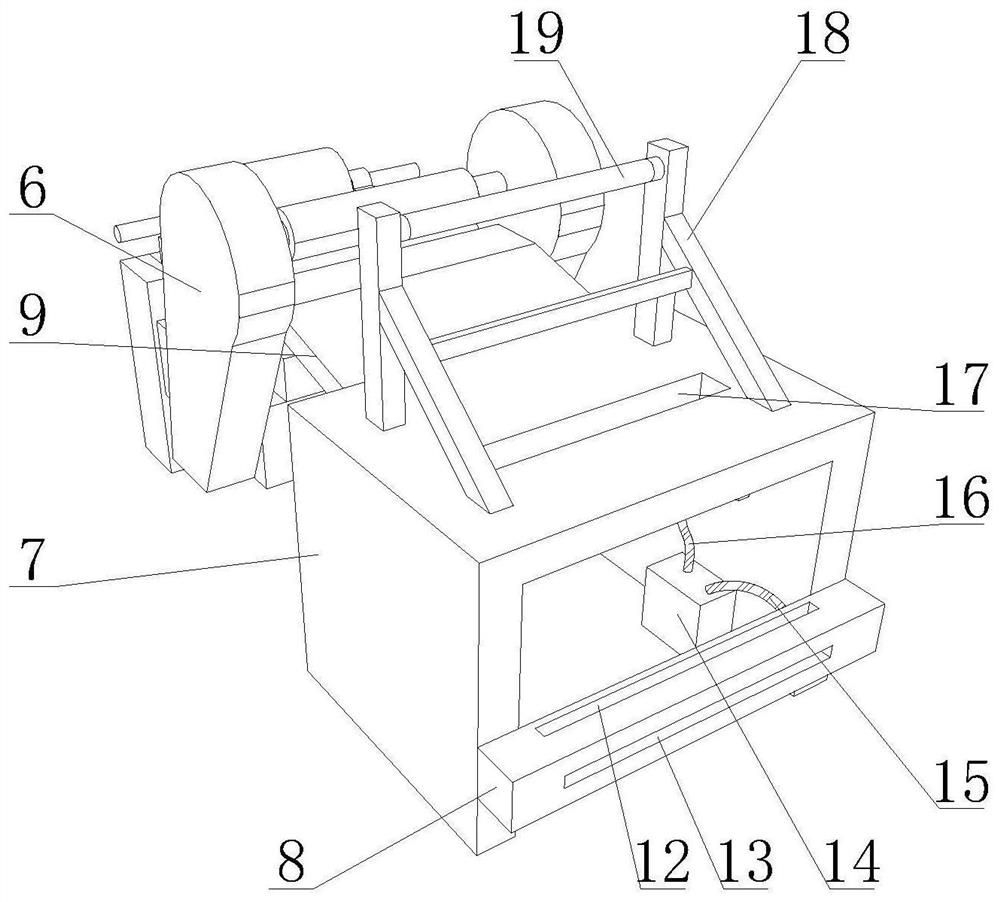

[0038] Such as Figure 1-5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the inner wall of the woven bag cutting body 7 is fixedly equipped with a control cutter 21, and one end of the second electric energy transmission line 16 is fixedly connected to the bottom of the control cutter 21 , the top of the control cutter 21 is fixedly connected with the control cable 20, the inwall of the woven bag cutting main body 7 is fixedly installed with a fixed controller 22, and the inboard of the fixed controller 22 is movably equipped with a movable cutting blade 24, and the control cable 20 One end is fixedly connected to the left side of the fixed controller 22, the inner side of the control cutter 21 is fixedly equipped with a woven bag cutter 23, and the control cutter 21 can control the fixed controller 22 and the woven bag cutter 23 inside the woven bag cutting main body 7 1. The movable cutting blade 24 cuts the woven bag, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com