Combined water feed tank

A water supply tank and combined technology, which is applied in the configuration of water supply devices, water supply pools, buildings, etc., can solve problems such as affecting service life, decline in corrosion performance, stress corrosion, etc., so as to protect physical and mental health, purify the environment, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

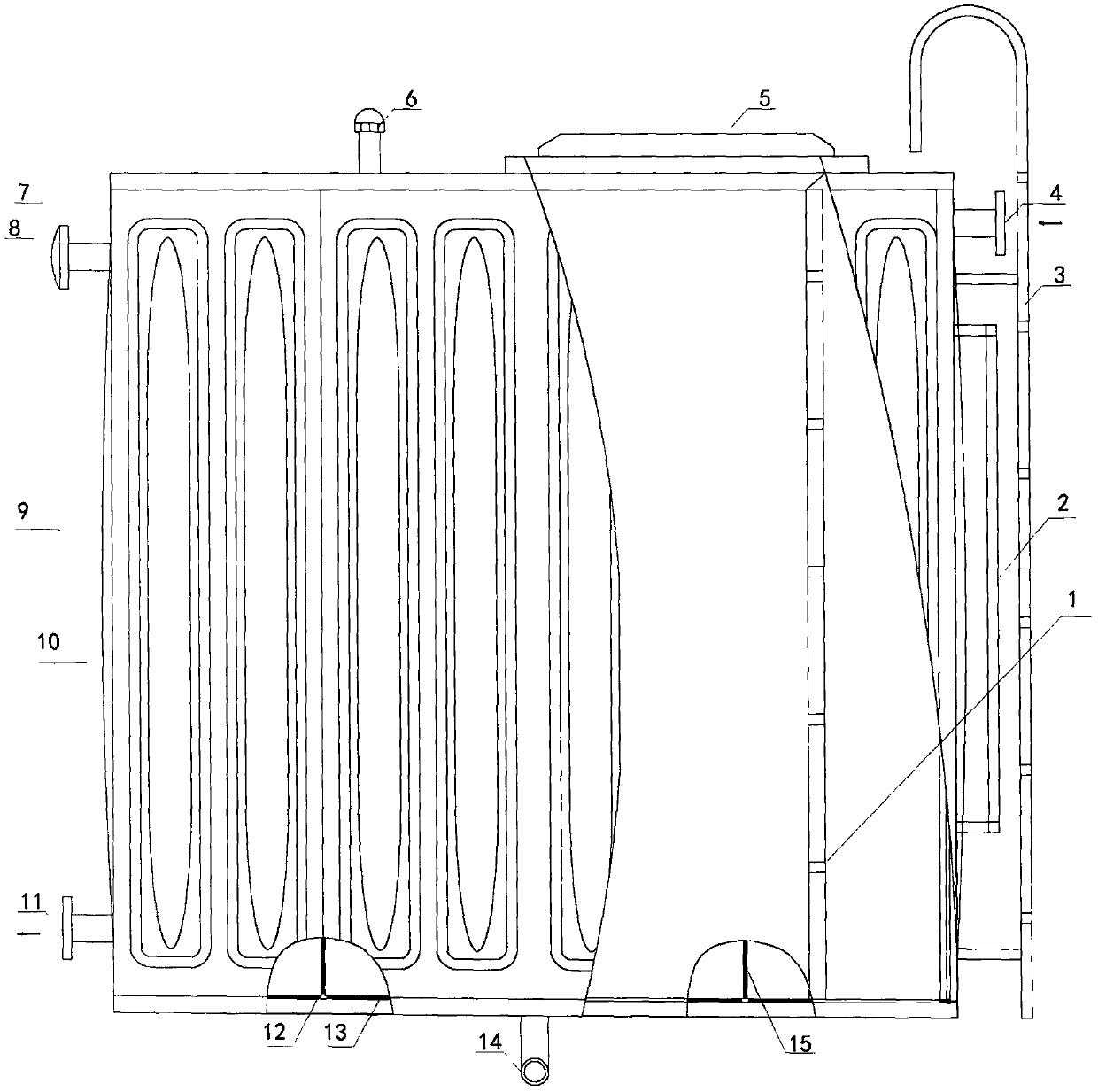

[0011] Below in conjunction with accompanying drawing, the water supply tank combined with 16 combined boards is an example, the present invention will be further described:

[0012] See attached figure 1 , the vertical sealing strip 15 is arranged between the combination plates 9, the vertical sealing strip 15 is connected with the horizontal sealing strip 13 through the tee connecting member 12, and the combination plates 9 and between the combination plate 9 and the bottom plate 16 are fixed with bolts to form a water supply tank;

[0013] The surface of the combined plate 9 is provided with reinforcing ribs 10; the water supply tank is provided with an inner ladder 1 and an outer ladder 3, the upper end of one side of the combined plate 9 is provided with a water inlet 4, and the lower end of the other side is provided with a water outlet hole 11; The upper end of one side of the plate 9 is provided with an overflow valve 7, and the outer end of the overflow valve 7 is fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com