Water hose storage method of water hose robot and water hose robot

A robot and hose technology, applied in the field of robotics, can solve the problems of the hose winding device being inflexible, single-function, and not strong in mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

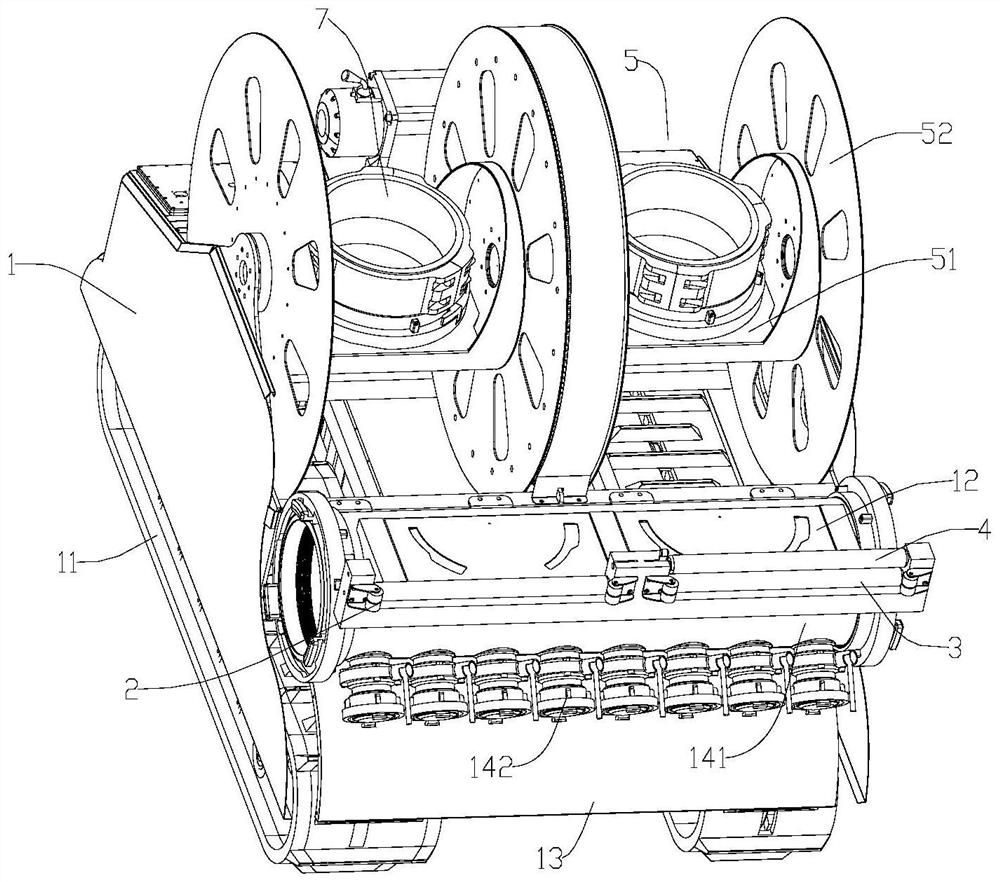

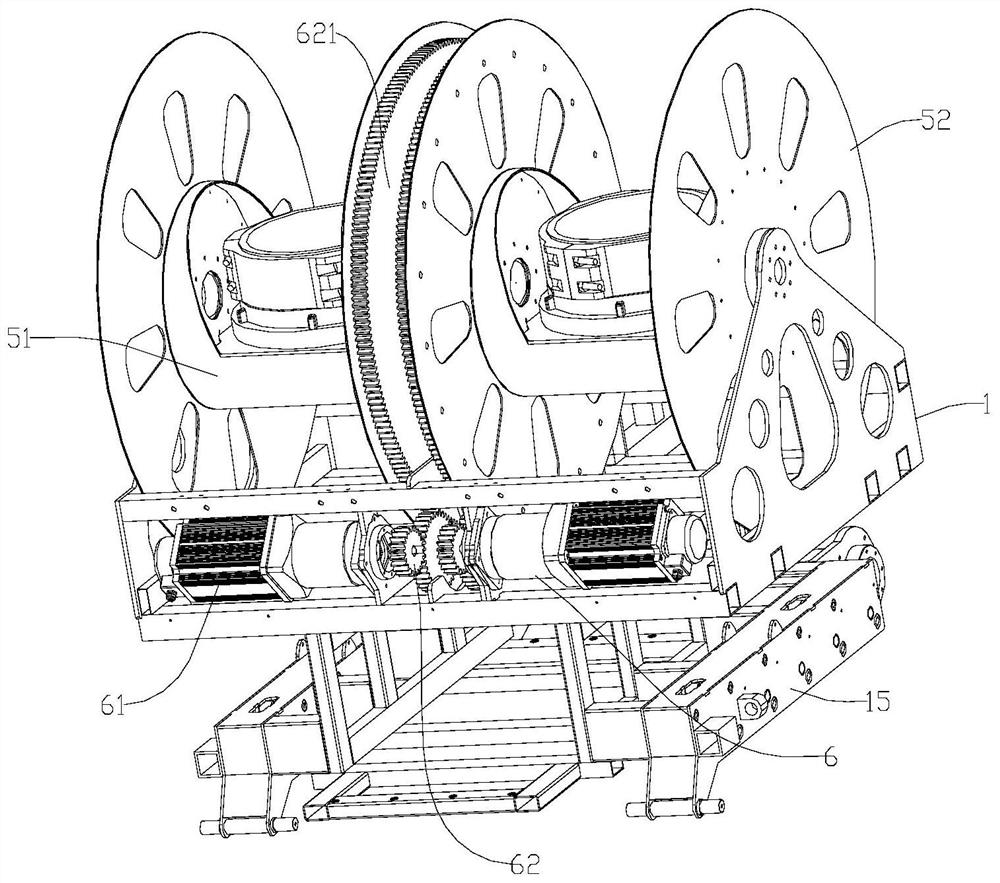

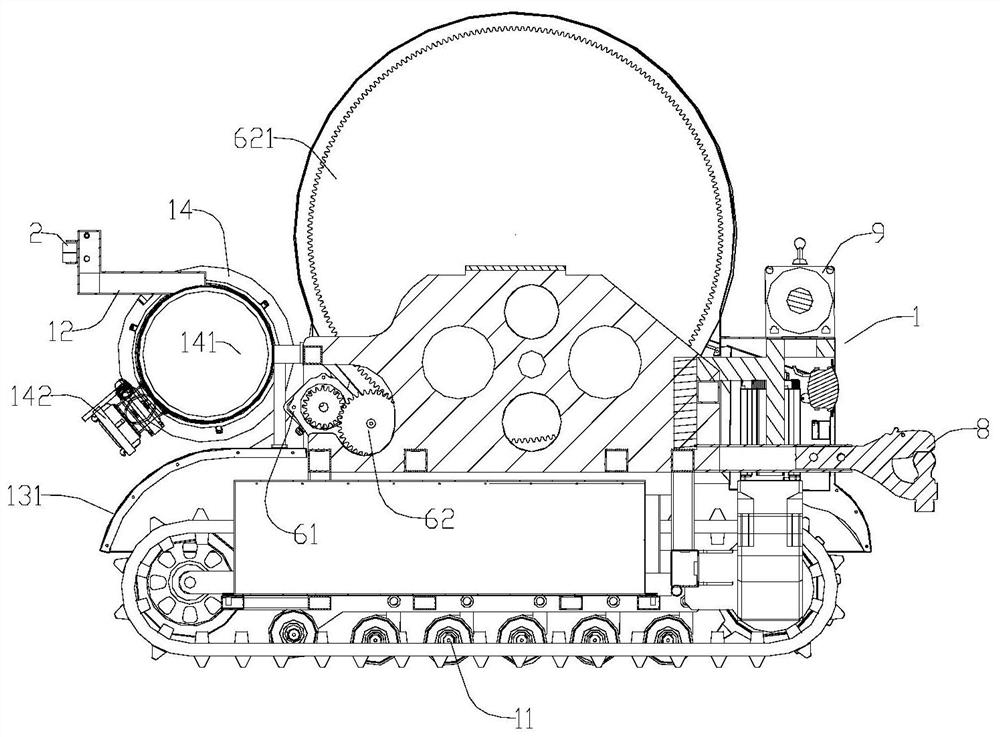

[0038] combined with Figures 1 to 5 A hose storage method of a hose robot of the present invention is described.

[0039] Such as Figure 1 to Figure 5 The hose robot shown includes a main body 1 of the hose robot, a walking mechanism, a hose reel 5, a water distribution pipe 14 and a limit roller, the walking structure is a crawler belt walking mechanism 11, and the hose reel 5 includes The rotating body 51 and the driving device 6, the crawler walking mechanism 11 is arranged at the bottom of the main body 1, and the crawler walking mechanism 11 can increase the obstacle-surmounting ability of the hose robot, so that it can adapt to most construction work scenarios. Operation: the hose reel 5 is installed on the main body 1, the rotating body 51 of the hose reel 5 is used to install the hose joint 7, and the driving device 6 drives the rotating body 51 to rotate. And in order to simplify the structure of the hose robot, the crawler walking mechanism 11 and the driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com