Shear wall construction abutted seam formwork connecting structure and supporting method

A technology for connecting structures and shear walls, which is applied to the joints of formwork/formwork/work frame, formwork/formwork/work frame, and building structures, etc., which can solve the problems of low construction efficiency, weak leak resistance, high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

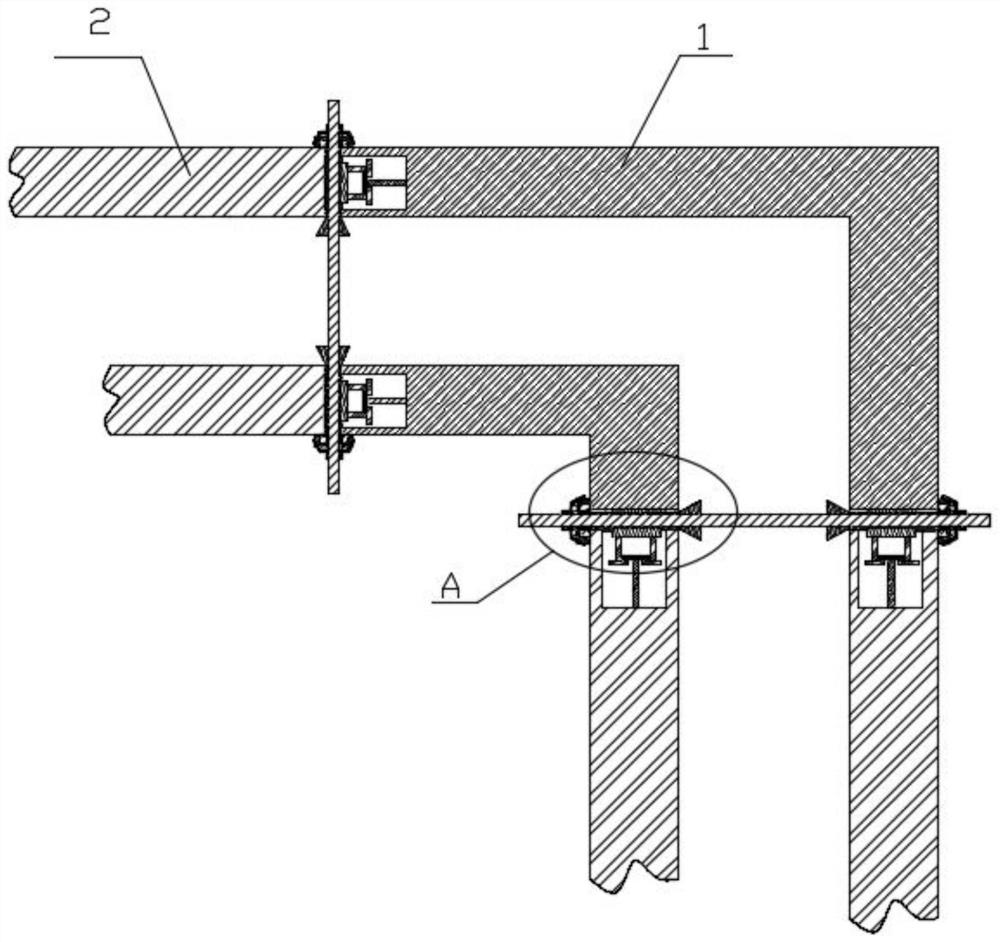

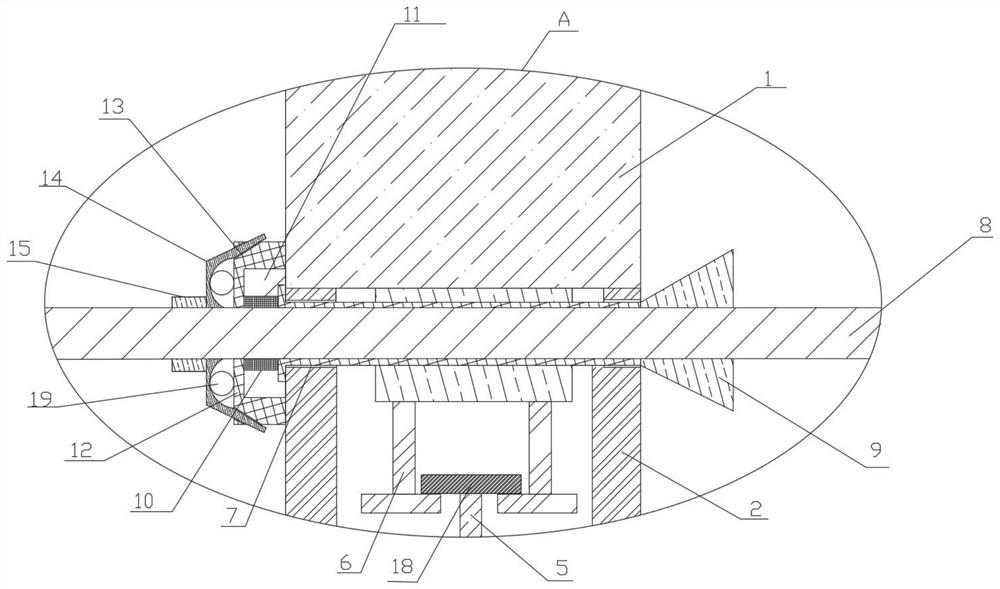

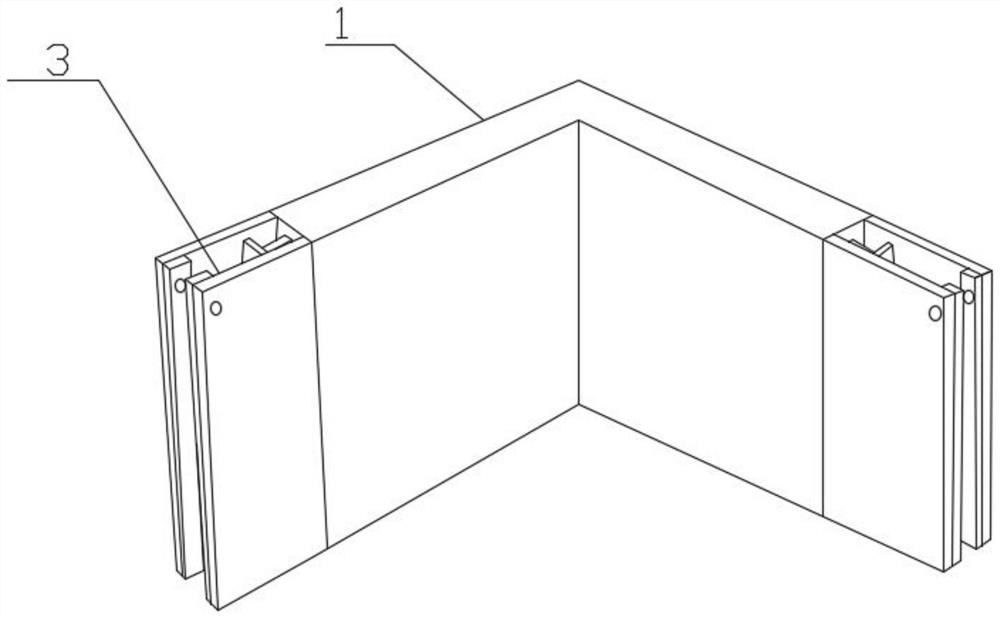

[0034] Such as figure 1 Shown: . A connection structure of joint formwork for shear wall construction, comprising a main formwork 1 and a connection formwork 2, the main formwork 1 includes a connection part one 3, the connection formwork 2 includes a connection part two 4, and the connection part one 3 is A connecting plate 5 is installed, and the connecting part 2 4 includes two sets of limiting plates 6 arranged side by side. Board 6 socket;

[0035] The main formwork 1 and the connecting formwork 2 are all provided with two groups and are installed on both sides of the shear wall to be poured, and the two sides of the connecting part 4 and the connecting part one 3 are all provided with installation holes 7, and the installation holes 7 is provided with two groups, and two groups of bolts 8 are installed in the installation holes 7, and blocking sleeves 9 are installed on the two groups of bolts 8, and two groups are installed on the blocking sleeves 9. The blocking sle...

Embodiment 2

[0048] Such as Figure 7 As shown, it is another embodiment of the present invention. On the basis of Example 1, it is added that the limiting plate 6 and the connecting plate 5 are both in the shape of a fishhook.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com