Plugging method for pressure-bearing dewatering well of high-water-level basement

A technology for dewatering wells and basements, applied in construction, infrastructure engineering, etc., can solve the problems of difficult installation of blind plates, unsatisfactory sealing effect, etc., and achieve the effect of ensuring welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

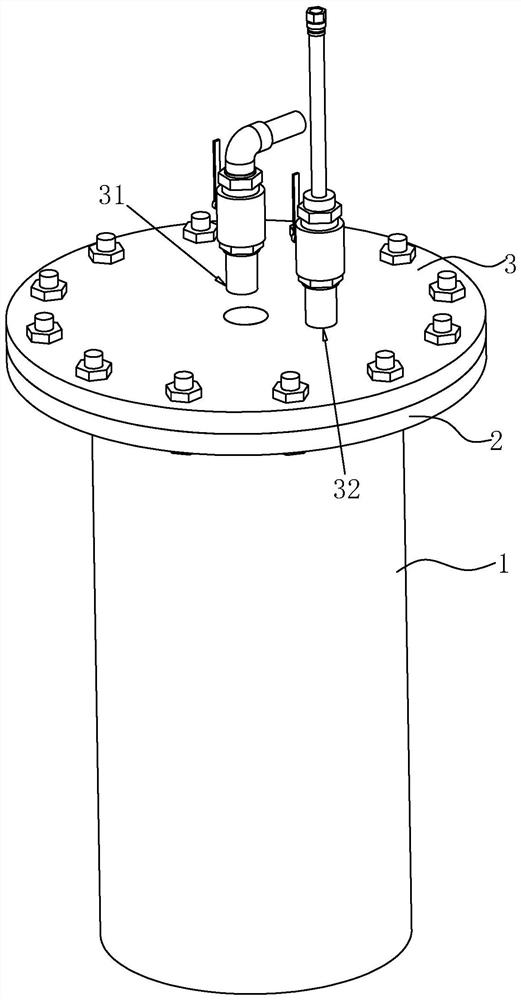

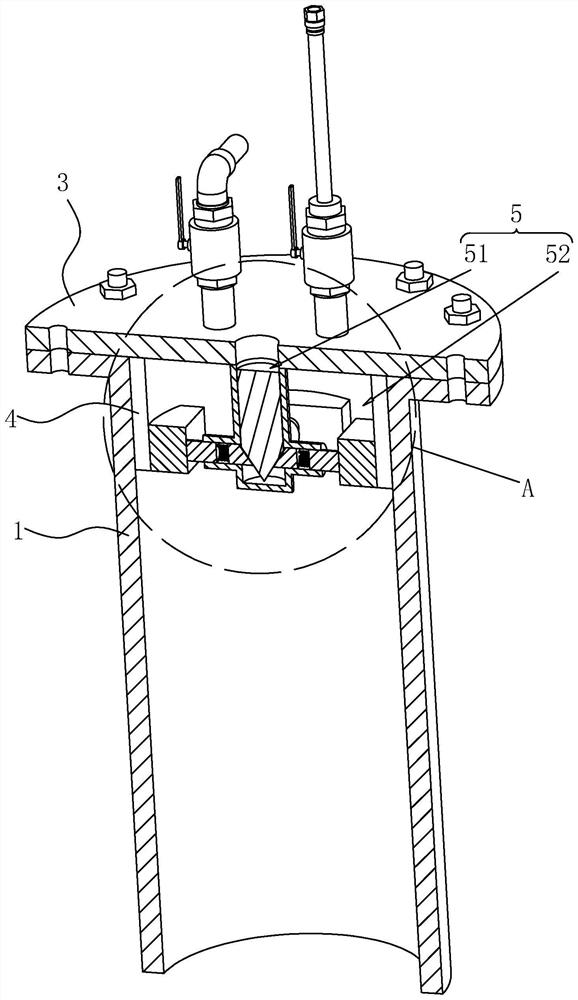

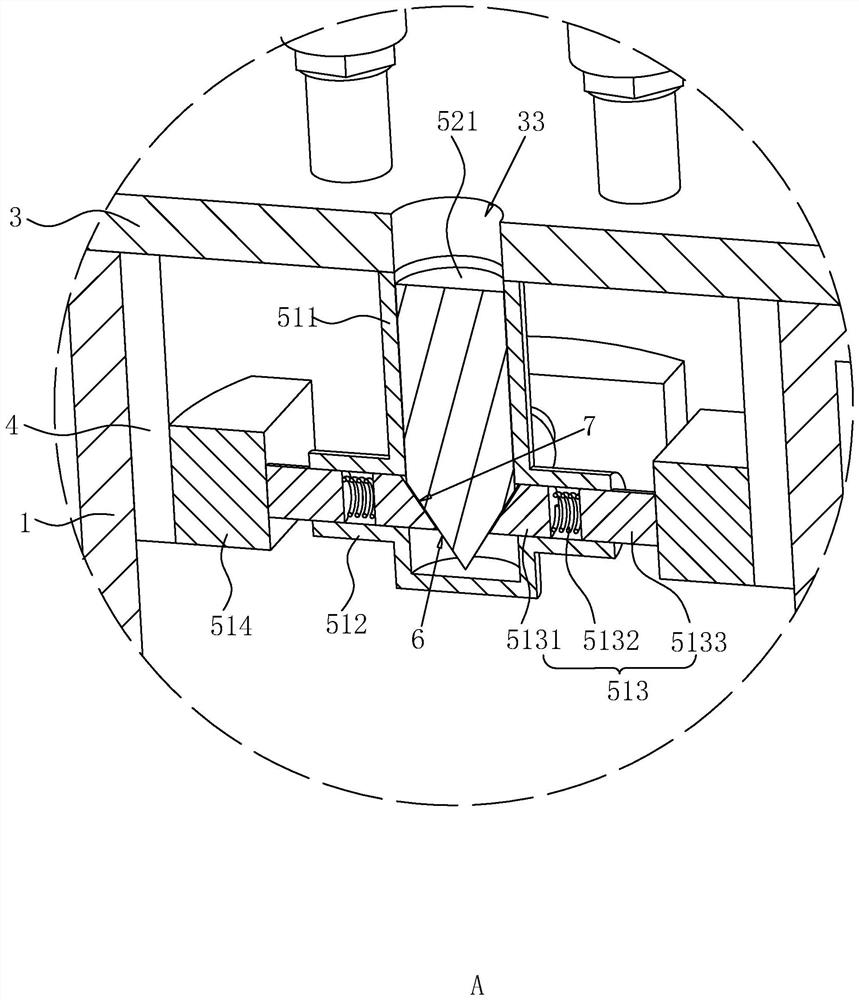

[0041] The following is attached Figure 1-3 The application is described in further detail.

[0042] The embodiment of this application discloses a method for sealing water wells under pressure in high-water level basements. figure 1 , 2 , including the following steps:

[0043] Installation steps of water-stop steel casing: make a suitable water-stop steel casing 1 according to the size of the dewatering well, lower the water-stop steel casing 1 into the dewatering well, and weld the flange on the top of the water-stop steel casing 1 in advance 2, so that the flange 2 is outside the dewatering well;

[0044]Blind plate installation steps: glue a circle of waterproof rubber ring 4 matching the inner pipe diameter of water-stop steel casing 1 in the center of the plate surface of blind plate 3, and then place the plate surface inside the waterproof rubber ring 4 on the blind plate 3 Install an abutting device 5 on it, align the waterproof rubber ring 4 with the water-stop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com