Water blocking method used in water blocking system of model aircraft

A technology of blocking water and model aircraft, applied in the direction of ships, etc., can solve the problems of hindering the power output of the electric motor, damaging the electric motor, insufficient power of the model, etc., and achieving the effect of improving the comprehensive performance and reducing the friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

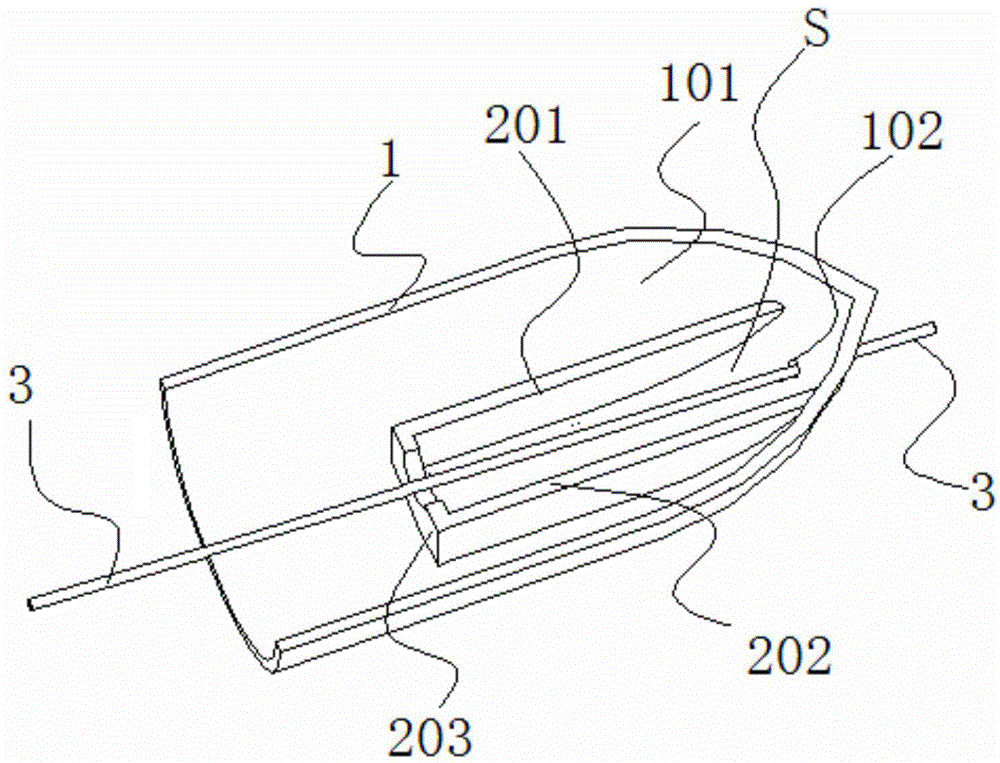

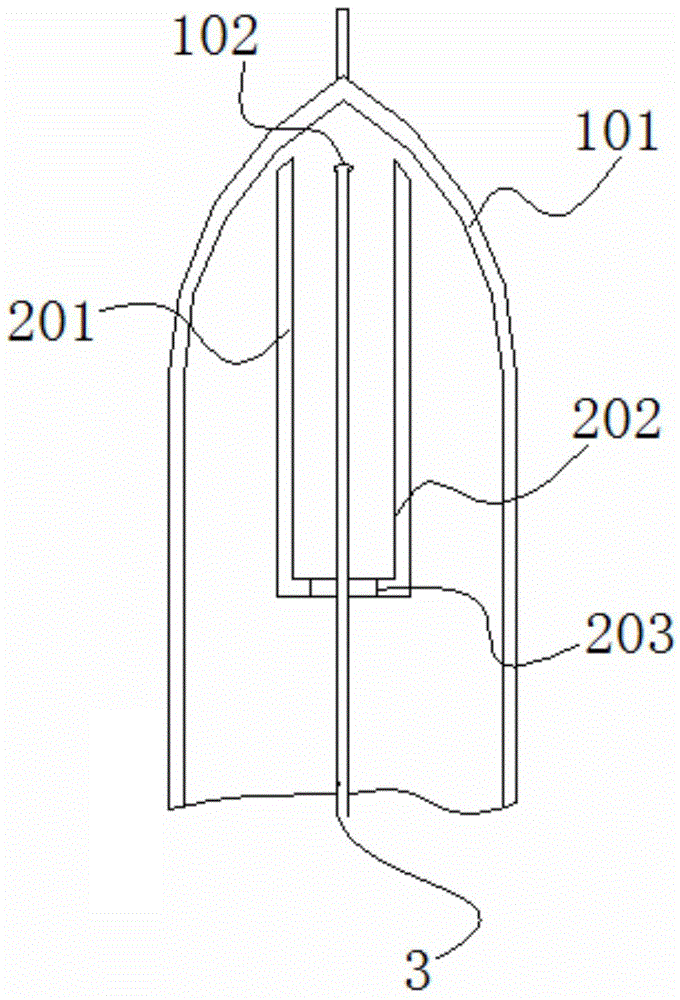

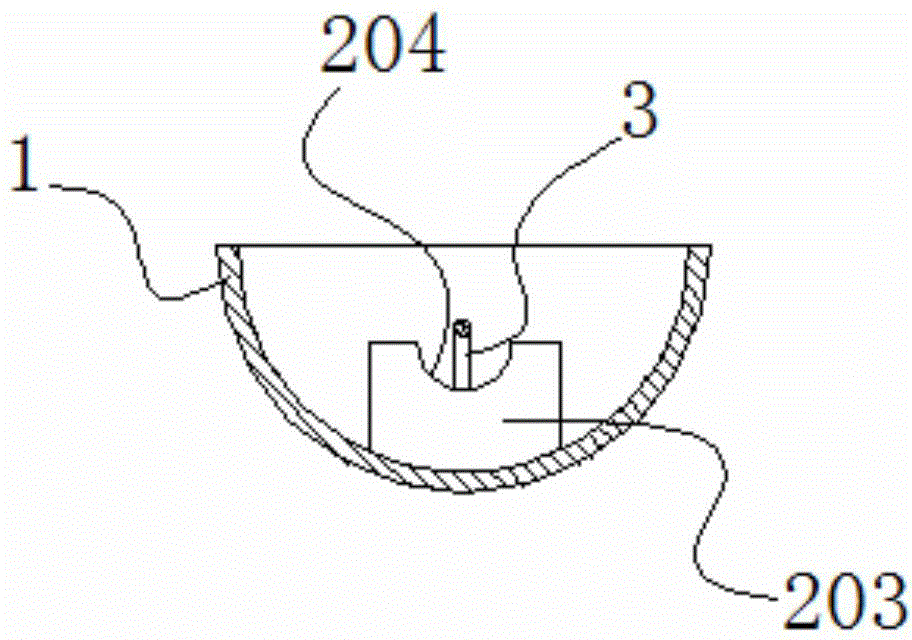

[0029] This embodiment discloses a water blocking method for an airplane model, which includes a model airplane hull 1, a propeller shaft 3, and a first longitudinal rib 201, a second longitudinal rib 202, and a transverse rib 203 installed inside the airplane model hull 1. Aeromodelling water blocking system.

[0030] The stern 101 of the model airplane hull 1 is provided with a propeller water inlet hole 102 . One end of the propeller shaft 3 is connected to the electric motor, and the other end passes through the propeller water inlet 102, and then the propeller is installed. see figure 1 Or 4, the propeller shaft 3 is obliquely inserted into the propeller water inlet hole 102, and the end of the propeller shaft 3 connected to the electric motor is higher than the position of the propeller water inlet hole 102. It is worth noting that, in most aircraft models, the propeller shaft 3 is connected with the output shaft of the electric motor through a rubber sleeve.

[0031]...

Embodiment 2

[0039] This embodiment discloses a water blocking method for an airplane model, which includes a model airplane hull 1, a propeller shaft 3, and a first longitudinal rib 201, a second longitudinal rib 202, and a transverse rib 203 installed inside the airplane model hull 1. Aeromodelling water blocking system.

[0040] The stern 101 of the model airplane hull 1 is provided with a propeller water inlet hole 102 . One end of the propeller shaft 3 is connected to the electric motor, and the other end passes through the propeller water inlet 102, and then the propeller is installed. see figure 1Or 4, the propeller shaft 3 is obliquely inserted into the propeller water inlet hole 102, and the end of the propeller shaft 3 connected to the electric motor is higher than the position of the propeller water inlet hole 102. It is worth noting that, in most aircraft models, the propeller shaft 3 is connected with the output shaft of the electric motor through a rubber sleeve. In this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com