Header-system connecting system based on high-pressure cylinder zero output and reheat steam and operation method

A technology for reheating steam and high-pressure cylinders, which is applied in steam generation, steam engine installations, steam generation installations, etc., can solve problems such as dependence on thermal electrolysis coupling technology, and achieve the effect of flexible load distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings.

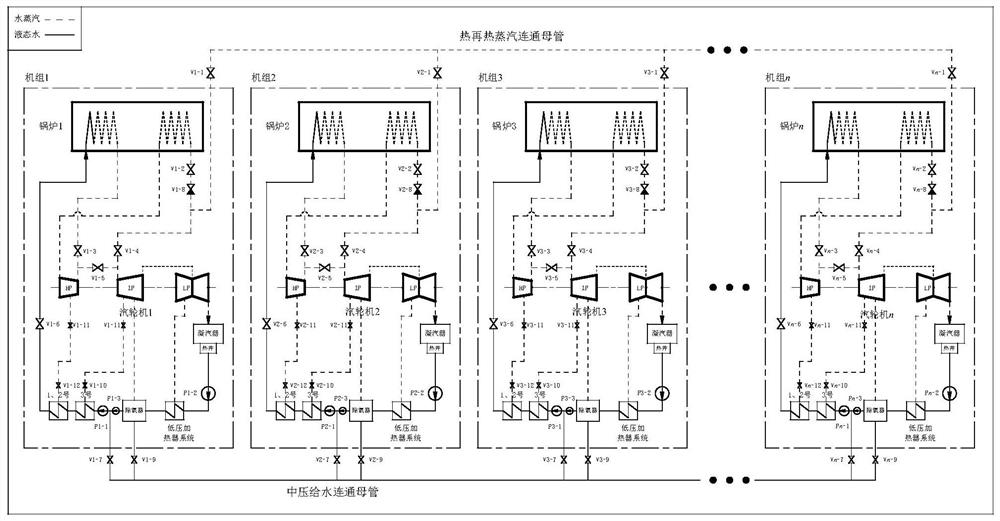

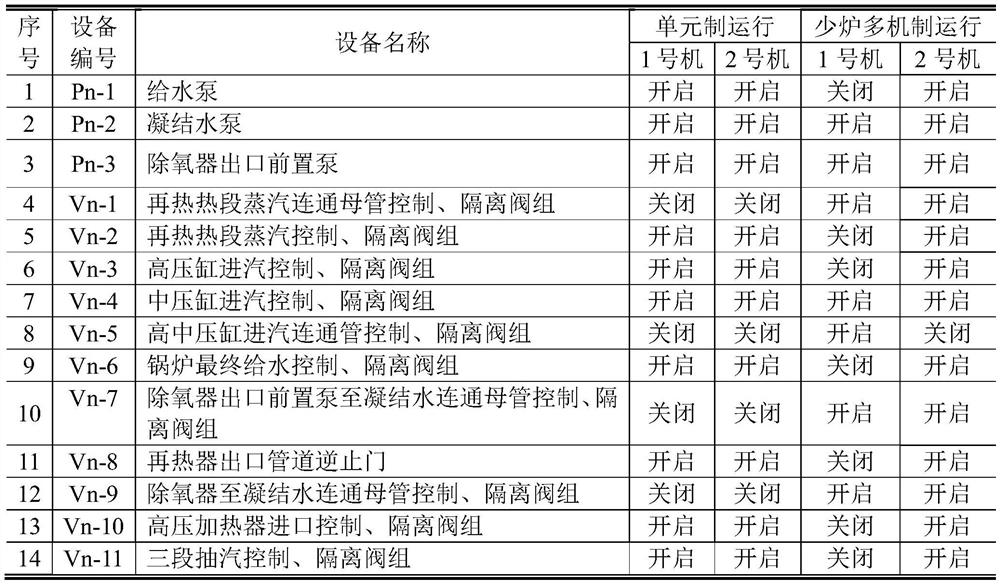

[0039] see figure 1 , The present invention provides a connection system and operation method based on high-pressure cylinder zero output and reheat steam main pipe, including conventional boilers, steam turbine steam-water systems and extension systems. Among them, the additional system includes: the main pipe connecting the steam in the reheating hot section, the connecting pipe connecting the condensed water, the connecting pipe connecting the deaerator to the condensed water connecting the main pipe, the connecting pipe connecting the steam inlet of the high and medium pressure cylinder and the corresponding control, shutting off the valve group, and reheating. The check valve of the outlet pipe of the heater and the medium-pressure combined steam valve are transformed into adjustable medium-pressure combined steam valves.

[0040] Wherein, the steam-water syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com