A processing method of bamboo-wood composite cross-laminated wood and the resulting product

A bamboo-wood composite and processing method technology, applied in wood processing appliances, layered products, wood layered products, etc., can solve the problem of bending and tensile failure, low bending strength and rigidity, rolling shear damage to the surface layer board and other problems, to achieve the effects of high integrity, reduced self-weight burden, excellent gluing performance and anti-rolling shear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

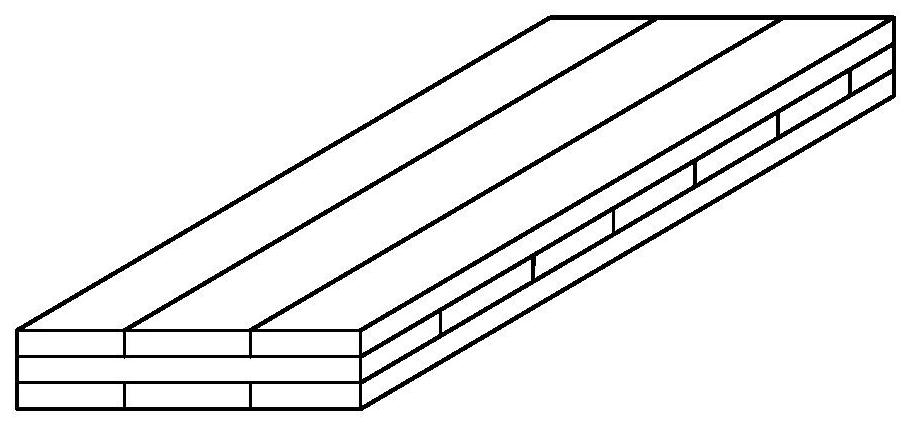

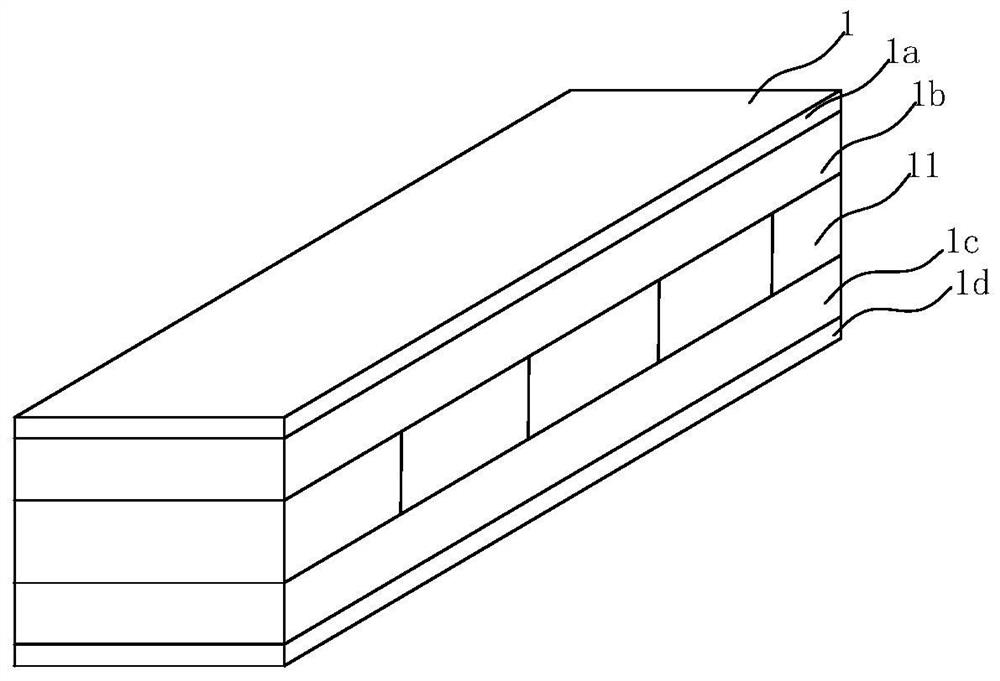

[0044] Such as Figure 3 to Figure 4 As shown, the present embodiment takes the bamboo-wood composite CLT (cross-laminated timber) of the three-layer structure as an example, and adopts the recombined bamboo material in the spruce-pine-fir (Spruce-pine-fir, SPF) wood and the bamboo material To make bamboo-wood composite CLT, the technical solutions involved in the specific production process are:

[0045] A hierarchical structure is set up sequentially from top to bottom. Layer 1 is the upper surface composite outer layer in the composite outer layer 1, including the outermost layer 1a and the second outer layer 1b. The outermost layer 1a is made of recombined bamboo material, and the grain direction is along the In the length direction, the second outer layer 1b adopts SPF material, and the texture direction is along the length direction; layer two is the second layer 11, which is the middle layer (symmetrical laminate) in this embodiment, and the symmetrical laminate is a ho...

Embodiment 2

[0057] On the basis that other technical solutions of embodiment 1 remain unchanged, the difference is that in this embodiment:

[0058] S5. Glue application: Apply a structural adhesive to the surface to be glued of the cross-laminated wood substrate as a load-bearing member. The adhesive is a one-component polyurethane adhesive, and the amount of glue applied is 180g / m 2 ;

[0059] S7. Pressure curing: Under the condition that the ambient temperature is higher than 15°C, pressurize the four sides of the cross-glued wood board, specifically: pressurize in the up and down directions, the pressurized pressure is 1.5MPa, and pressurize the sides in the width direction, The pressurization pressure is 0.4MPa, and the pressurization time is 3h.

[0060] In this embodiment, the moisture content of the material is preferably 13%, which can best realize the penetration and gluing of the adhesive to the material in this embodiment, and improve the overall bonding strength of the cross...

Embodiment 3

[0063] Such as Figure 5 , Figure 6 As shown, the present embodiment takes the bamboo-wood composite CLT (cross-laminated timber) of the five-layer structure as an example, and adopts the recombined bamboo material in the spruce-pine-fir (Spruce-pine-fir, SPF) wood and the bamboo material To make bamboo-wood composite CLT, the technical solutions involved in the specific production process are:

[0064]A hierarchical structure is set up sequentially from top to bottom. Layer 1 is the upper surface composite outer layer in the composite outer layer 1, including the outermost layer 1a and the second outer layer 1b. The outermost layer 1a is made of recombined bamboo material, and the grain direction is along the In the length direction, the second outer layer 1b is made of SPF material, and the grain direction is along the length direction; the second layer is the second layer 11, which is a transverse layer, made of recombined bamboo material, and the grain direction is along...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com